Concrete seal primer and preparation method thereof

A technology for sealing primer and concrete, applied in primers, coatings, epoxy resin coatings, etc., can solve problems such as difficulty in achieving protection, coating powdering, coating efflorescence, etc., and achieve excellent anti-settling effect, adhesion Good focus and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

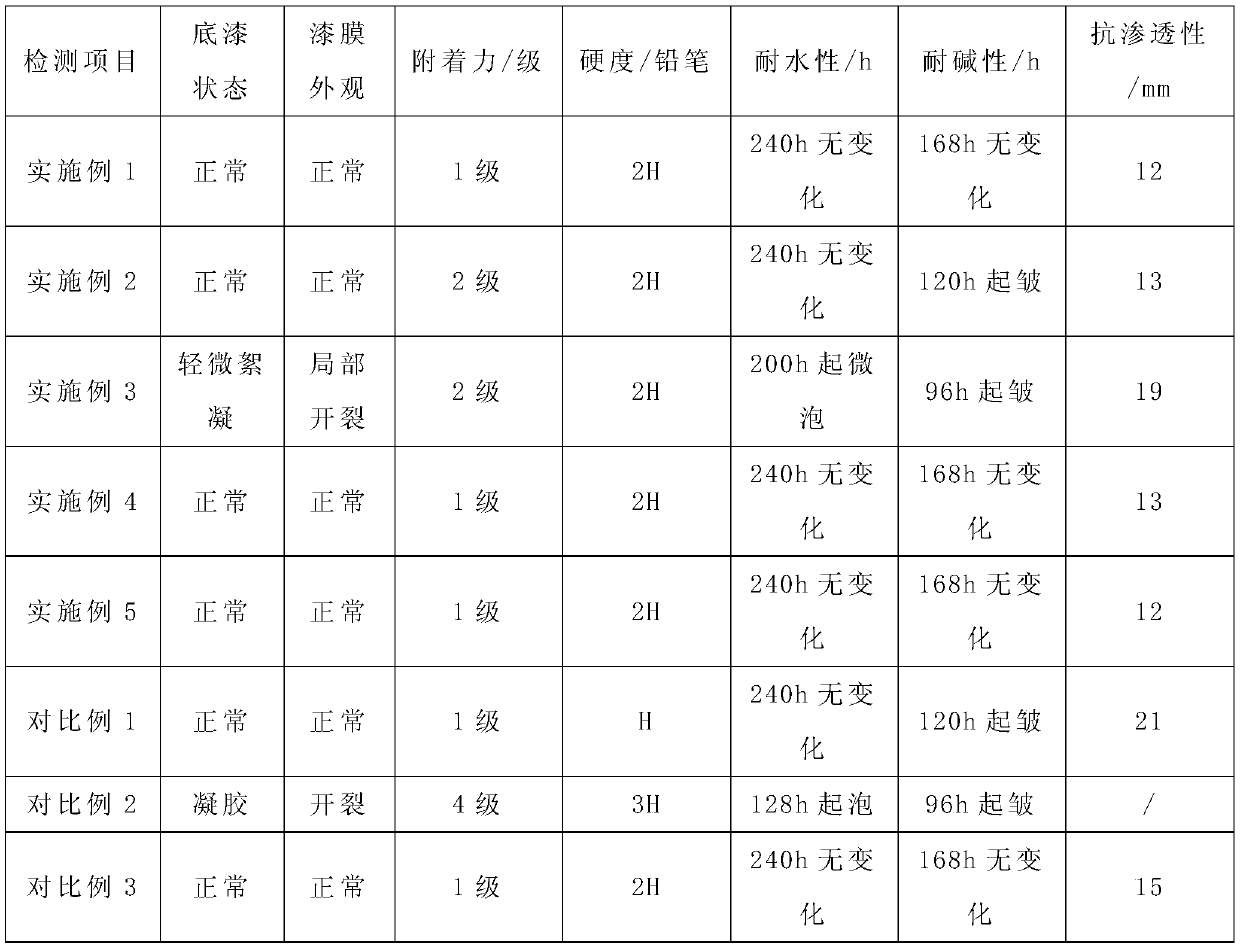

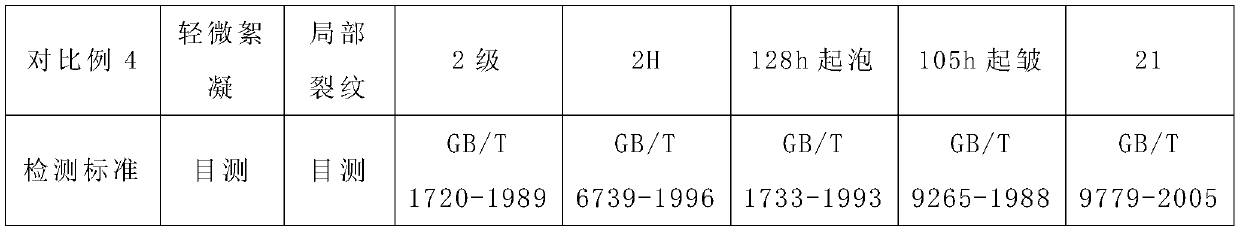

Examples

Embodiment 1

[0031] A concrete sealing primer, composed of two components A and B according to the mass ratio of 10:1,

[0032] Component A main paint: 40 parts of epoxy resin, 0.5 parts of TEGO 810, 0.5 parts of TEGO 280, 2.5 parts of CS-122, 2 parts of ethylene glycol butyl ether, 0.2 parts of bentonite, 5 parts of titanium dioxide, 15 parts of mica powder, talc Powder 5 parts, calcium carbonate 5 parts, nano silica sol THIS-S30 15 parts, deionized water 9.3 parts.

[0033] B component curing agent: 50 parts of amine curing agent, 50 parts of deionized water.

[0034] The above-mentioned component A and component B are prepared into concrete sealing primer according to the following method, and the steps are:

[0035] (1) Add quantitative deionized water into the agitator according to the formula amount, and add co-solvent, defoamer, wetting agent, pigment and filler in order under stirring at a speed of 500r / min, and increase the speed to 1500r after stirring evenly / min, disperse eve...

Embodiment 2

[0039] A concrete sealing primer, composed of two components A and B according to the mass ratio of 10:1,

[0040] Wherein, A component comprises the raw material of following parts by weight:

[0041] 35 parts of epoxy resin, 1 part of dipropylene glycol butyl ether, 1 part of propylene glycol methyl ether, 0.5 parts of BYK022, 0.5 parts of TEGO500, 0.4 parts of bentonite, 10 parts of titanium dioxide, 15 parts of calcium carbonate, 10 parts of silica sol, 26.6 parts of deionized water ;

[0042] B component comprises the raw material of following parts by weight:

[0043] 43 parts of amine curing agent, 57 parts of deionized water.

[0044] The preparation method of above-mentioned concrete sealing primer is the same as embodiment 1.

Embodiment 3

[0046] A concrete sealing primer, composed of two components A and B according to the mass ratio of 10:1,

[0047] Wherein, A component comprises the raw material of following parts by weight:

[0048] 30 parts of epoxy resin, 3 parts of propylene glycol phenyl ether, 2 parts of dipropylene glycol methyl ether, 1 part of TEGO825, 1 part of BYK346, 0.5 parts of bentonite, 5 parts of sericite, 10 parts of calcium carbonate, 20 parts of silica sol, 27.5 parts of deionized water ;

[0049] B component comprises the raw material of following parts by weight:

[0050] 37 parts of amine curing agent, 63 parts of deionized water.

[0051] The preparation method of above-mentioned concrete sealing primer is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com