High-voltage high-curie-point potassium sodium niobate-potassium sodium antimonate series lead-free piezoelectric ceramic and preparation method thereof

A high Curie point, lead-free piezoelectric technology, applied in the field of lead-free piezoelectric ceramics, can solve the problems of narrowing the application temperature range and limiting the application range, so as to improve the structure density, improve the electrical performance and high temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

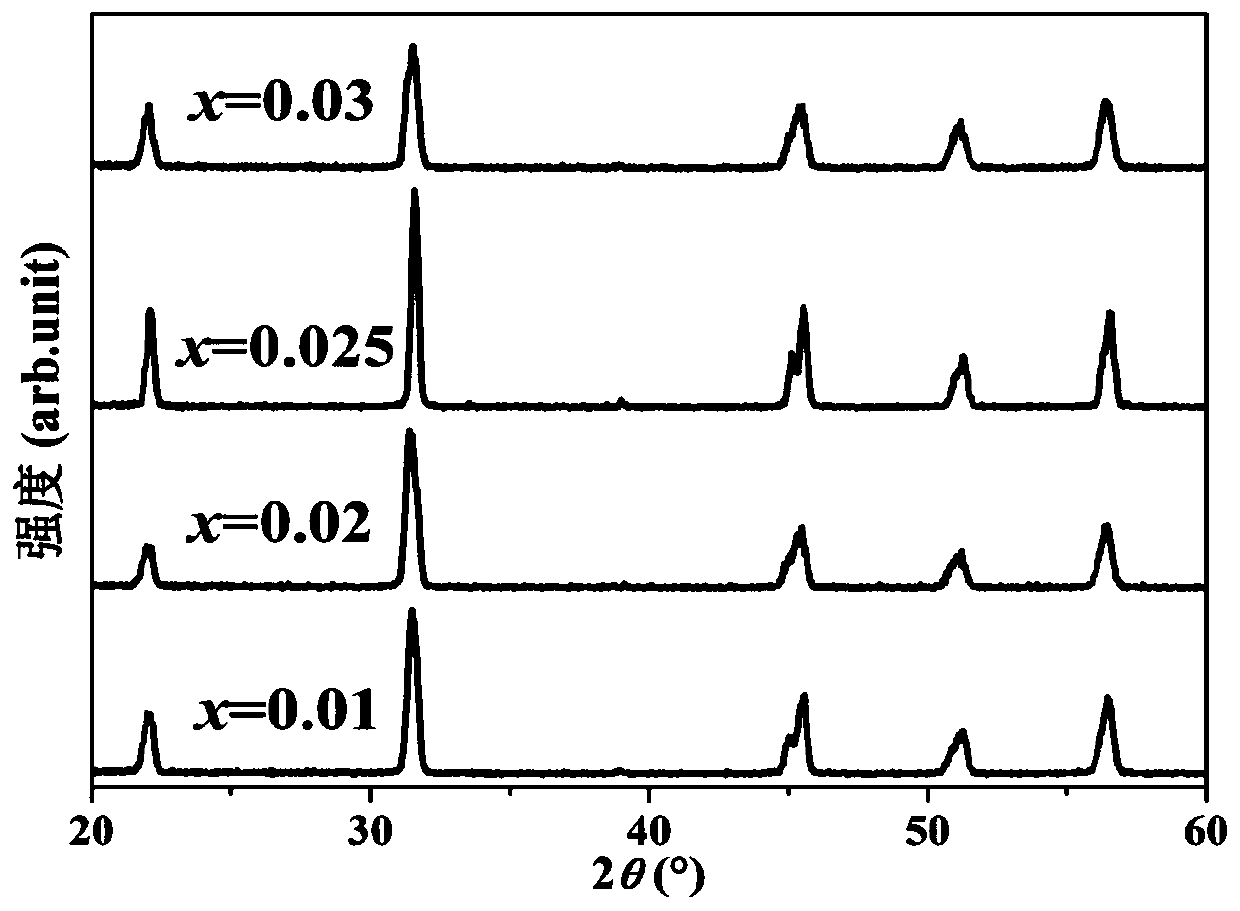

[0032] The present embodiment prepares by general formula 0.965[(1-x)K 0.54 Na 0.476 NbO 3 -xK 0.54 Na 0.476 SbO 3 ]-0.01Bi 2 o 3 -0.0025Fe 2 o 3 -0.03ZrO 2 The lead-free piezoelectric ceramic represented, x=0.01 (sample 1) in the formula, specifically comprises the following steps:

[0033] (1) Ingredients, in K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , Sb 2 O is the raw material, according to the general formula K 0.54 Na 0.476 NbO 3 and K 0.54 Na 0.476 SbO 3 Chemical formula for weighing ingredients;

[0034] (2) Pre-burning, the raw materials prepared in step (1) are milled with absolute ethanol as the ball milling medium, mixed and milled for 24 hours by rolling ball milling, and then dried to obtain dry powder, and then pre-fired at about 850 ° C for about 6 hours for K 0.54 Na 0.476 NbO 3 and K 0.54 Na 0.476 SbO 3 Synthesis;

[0035] (3) Ingredients, in K 0.54 Na 0.476 NbO 3 、K 0.54 Na 0.476 SbO 3 、 Bi 2 o 3 , Fe 2 o 3 , ZrO 2 As raw materia...

Embodiment 2

[0041] The present embodiment prepares by general formula 0.965[(1-x)K 0.54 Na 0.476 NbO 3 -xK 0.54 Na 0.476 SbO 3 ]-0.01Bi 2 o 3 -0.0025Fe 2 o 3 -0.03ZrO 2 The lead-free piezoelectric ceramic represented, x=0.02 (sample 2) in the formula, specifically comprises the following steps:

[0042] (1) Ingredients, in K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , Sb 2 O is the raw material, according to the general formula K 0.54 Na 0.476 NbO 3 and K 0.54 Na 0.476 SbO 3 Chemical formula for weighing ingredients;

[0043] (2) Pre-calcination, use absolute ethanol as the ball milling medium for the raw materials prepared in step (1), mix and ball mill for 24 hours by rolling ball milling method, then dry to obtain dry powder, and then pre-calcine the obtained dry powder at about 850°C for 6 hours K left and right 0.54 Na 0.476 NbO 3 and K 0.54 Na 0.476 SbO 3 Synthesis;

[0044] (3) Ingredients, in K 0.54 Na 0.476 NbO 3 、K 0.54 Na 0.476 SbO 3 、 Bi 2 o 3 , Fe 2 ...

Embodiment 3

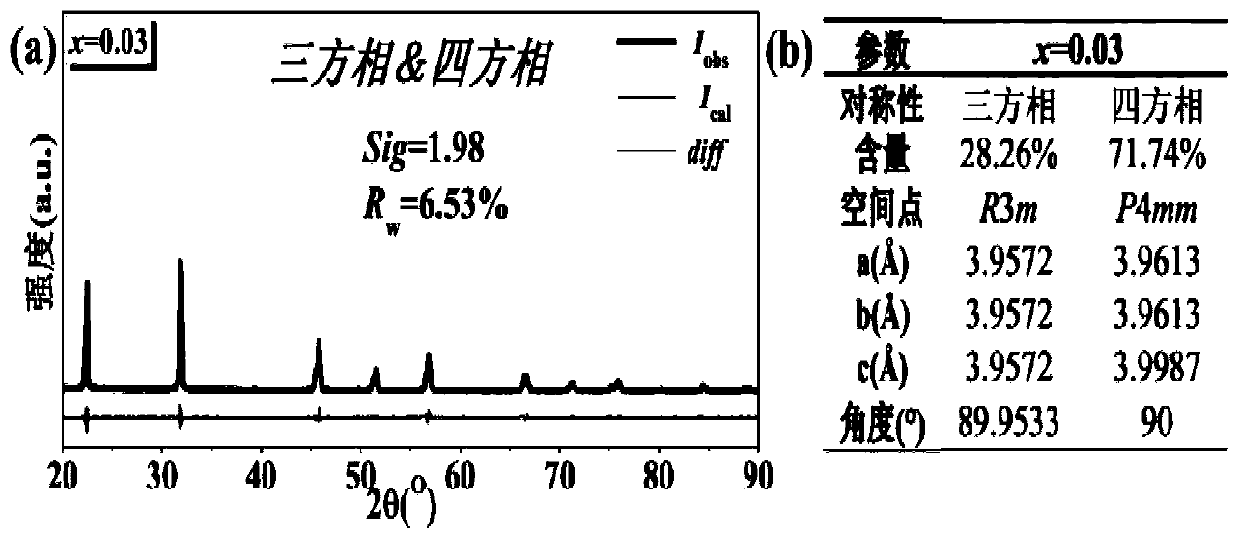

[0050] The present embodiment prepares by general formula 0.965[(1-x)K 0.54 Na 0.476 NbO 3 -xK 0.54 Na 0.476 SbO 3 ]–0.01Bi 2 o 3 -0.0025Fe 2 o 3 -0.03ZrO 2 The lead-free piezoelectric ceramic represented, x=0.025 (sample 3) in the formula, specifically comprises the following steps:

[0051](1) Ingredients, in K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 As raw material, according to general formula K 0.54 Na 0.476 NbO 3 and K 0.54 Na 0.476 SbO 3 Chemical formula for weighing ingredients;

[0052] (2) Pre-calcination, use absolute ethanol as the ball milling medium for the raw materials prepared in step (1), mix and ball mill for 24 hours by rolling ball milling method, then dry to obtain dry powder, and then pre-calcine the obtained dry powder at about 850°C for 6 hours K left and right 0.54 Na 0.476 NbO 3 and K 0.54 Na 0.476 SbO 3 Synthesis;

[0053] (3) Ingredients, in K 0.54 Na 0.476 NbO 3 、K 0.54 Na 0.476 SbO 3 、 Bi 2 o 3 , Fe 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com