3D printed volcanic pit-shaped texture ceramic and processing method thereof

A technology of 3D printing and processing methods, which is applied in the direction of additive processing, ceramic molding machines, manufacturing tools, etc., can solve the problems of single ceramic surface shape, easy aggregation of ceramic particles, and reduced green body strength, so as to shorten development time and enrich Surface effect, the effect of ensuring the strength of the green body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

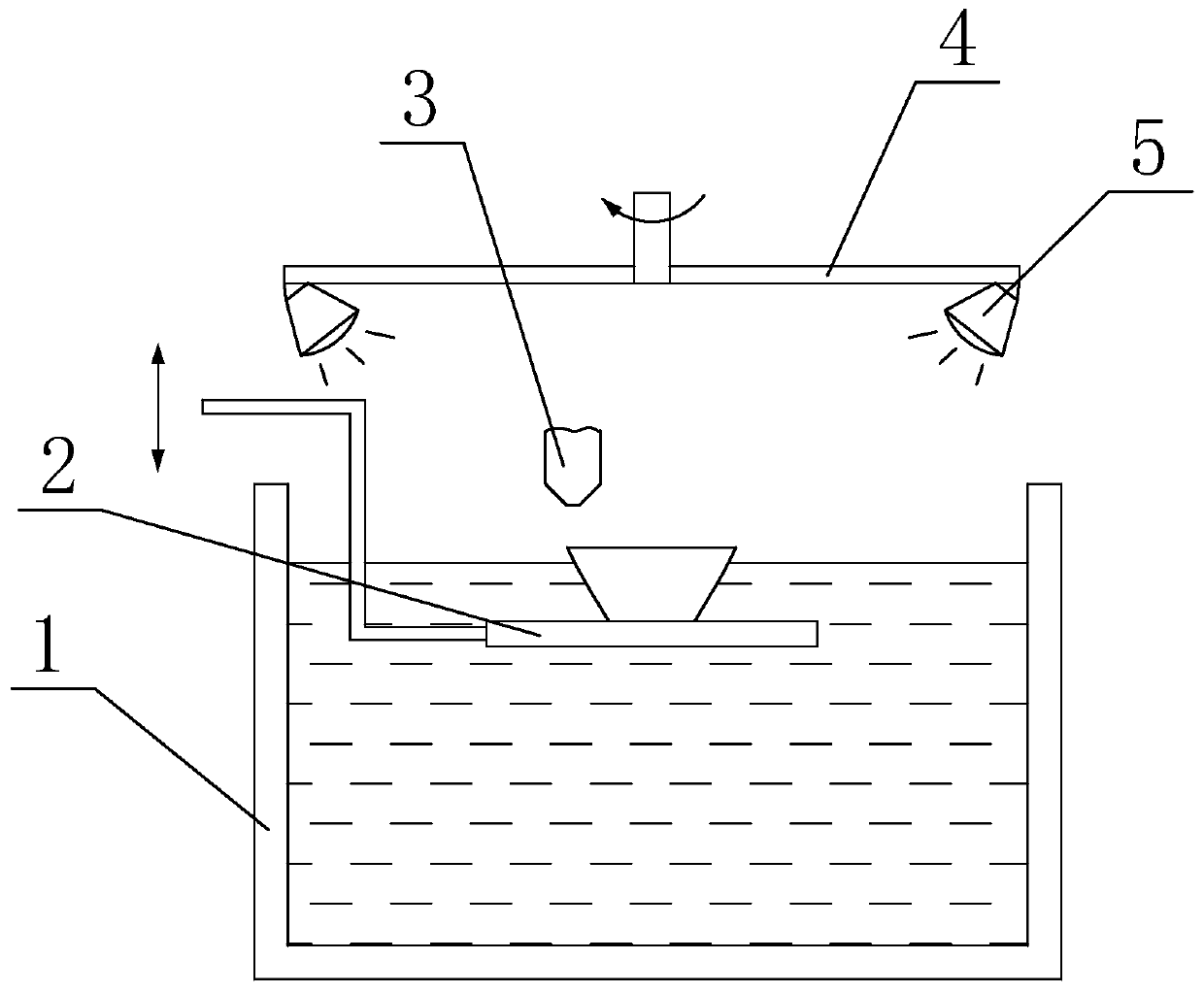

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments.

[0024] The 3D printing volcanic crater-like texture ceramics of the present invention includes the following components in parts by weight: 20-25 parts of kaolin, 10-12 parts of alumina, 5-8 parts of zirconia, 10-12 parts of calcium carbonate, surface 6-7 parts of active agent, 50-60 parts of methyl acrylate photocurable resin, 5-7 parts of dispersant, 10-20 parts of hydroxyapatite powder, and 30-40 parts of water; the glaze is in parts by weight, including the following Components: 30-40 parts of potassium feldspar, 20-25 parts of dolomite, 5-7 parts of calcium carbonate, 20-25 parts of kaolinite, 20-25 parts of quartz and 20-30 parts of water.

[0025] The surfactant is sodium dodecylbenzenesulfonate, and the dispersant is liquid polyacrylic acid sodium salt.

[0026] In specific implementation one, the blank includes the following components in parts by weight: 20 parts of kaolin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com