CPP cast film, composite film, preparation method of composite film and tinned sheet

A cast film and cast composite technology, applied in the field of packaging, can solve the problems of difficult printing with special appearance, high loss of printing iron, increase the cost of printing iron, etc., and achieve good corona treatment performance, high temperature resistance, and shear resistance Good performance and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

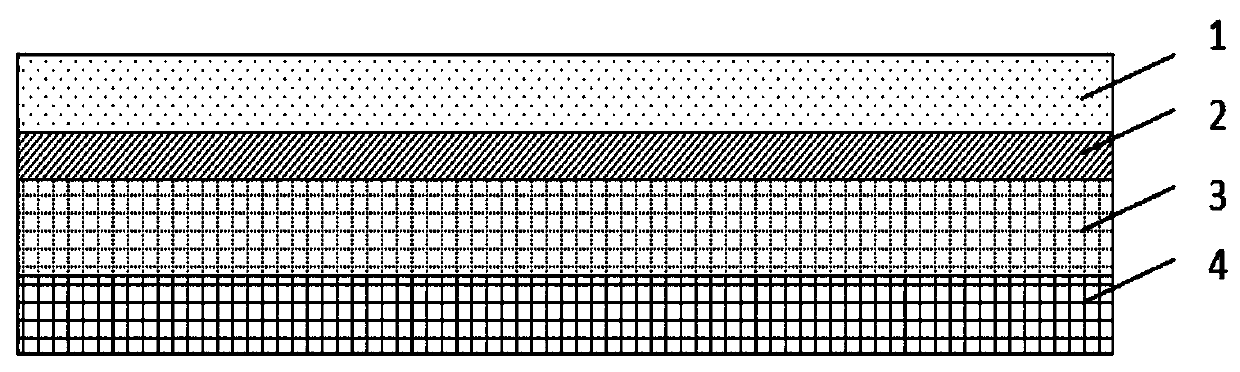

[0047] S1. Prepare the materials contained in the composite layer, intermediate layer and heat-sealing layer of the CPP cast film as described in Table 2 below, and weigh each component. The specific proportions of the three components in the heat-sealing layer are shown in Table 2. shown;

[0048] S2. Add the components of the composite layer, the middle layer and the heat-sealing layer into the multi-layer co-extrusion casting machine respectively, and obtain CPP streams with different resin ratios in the heat-sealing layer by means of three-layer co-extrusion molding. Extended film 1-6;

[0049] Table 2 Composition of composite layer, middle layer and heat seal layer of CPP cast film

[0050]

[0051] The heat-sealing layer resin ratio in the prepared CPP cast film 1-6 is shown in Table 3 below:

[0052] Table 3 CPP cast film 1-6 heat seal layer resin ratio

[0053] sample 18722—PP(%) OE850—PE(%) ABPP10S (%) CPP cast film 1 80 17 3 CPP cas...

Embodiment 2

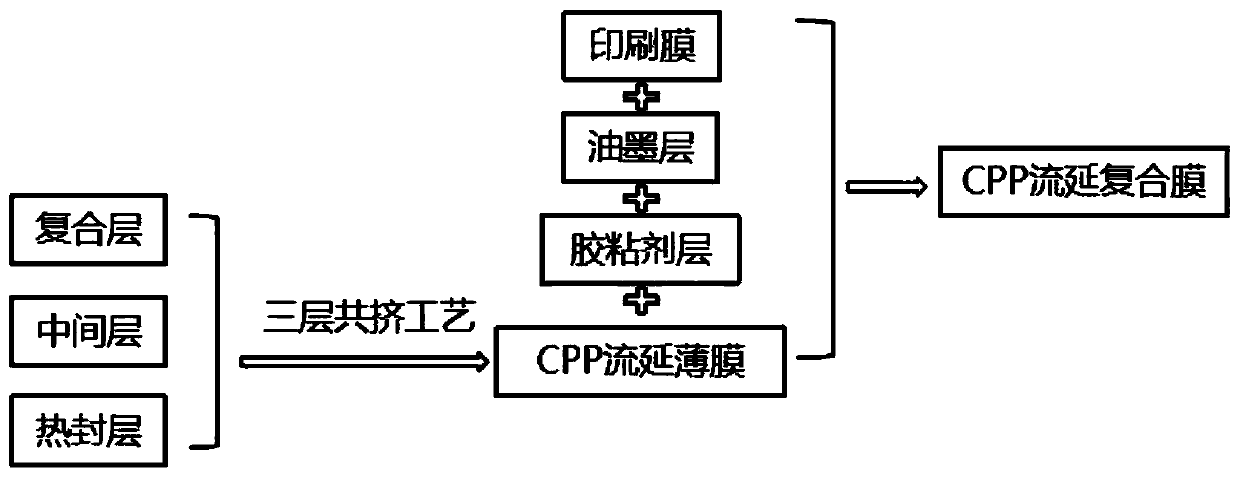

[0055] S1. Print ink on the printing film by gravure printing at a printing speed of 220-250m / min, dry and solidify the ink at 65-80°C to form an ink layer;

[0056] Using dry lamination or solvent-free lamination, the glue is evenly coated on the ink layer of the printing film with a rubber roller, and the amount of glue is 4.5-5.5gsm to form an adhesive layer;

[0057] S2. Heat and press the common film 1 prepared in Comparative Example 1 and the printed film through laminating rollers, the compounding temperature is 70-90°C, and the pressure is 0.2-0.4 MPa, wherein the adhesive layer of the common film and the printed film connected to each other, aged for 48-72 hours at a temperature of 45-55°C, and cooled at room temperature for more than 24 hours to prepare a common composite film 1, and to test the printing effect of the common composite film 1;

[0058] The CPP cast film 1-6 prepared in Example 1 is heated and pressed together with the printed film through the laminati...

Embodiment 3

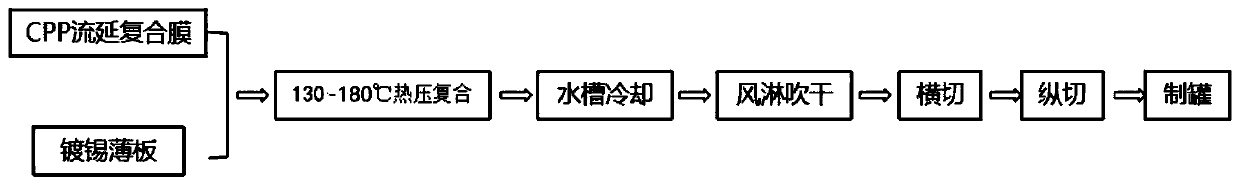

[0061] The ordinary composite film 1 prepared in Example 2 was heat-sealed and pressed with the tin-plated sheet at 120°C, 130°C, 140°C, 150°C, 160°C, 170°C, and 180°C respectively, and the hot-pressed Tin-plated sheet is used for heat-sealing performance test, and the strength value of heat-sealing performance is shown in Table 4 below;

[0062] The CPP cast composite films 1-6 obtained in Example 2 were heat-sealed and pressed with the tin-plated sheet at 120°C, 130°C, 140°C, 150°C, 160°C, 170°C, and 180°C respectively, and the The hot-pressed tin-plated sheet was tested for heat-sealing performance. The strength value of heat-sealing performance is shown in Table 4 below, and the curve of heat-sealing performance changing with temperature is shown in Figure 4 shown;

[0063] Table 4 Heat-sealing performance of composite film and tin-plated sheet at different temperatures (unit: N / 15mm)

[0064]

[0065] Note: The bold part in the table is the strength that meets the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com