Integrated oil mist purifier based on environmental engineering

An environmental engineering and integrated technology, applied in the direction of chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems that the purifier occupies a large area, occupies a large space, and has low purification efficiency, and achieves clean , avoid poor adsorption effect and improve purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

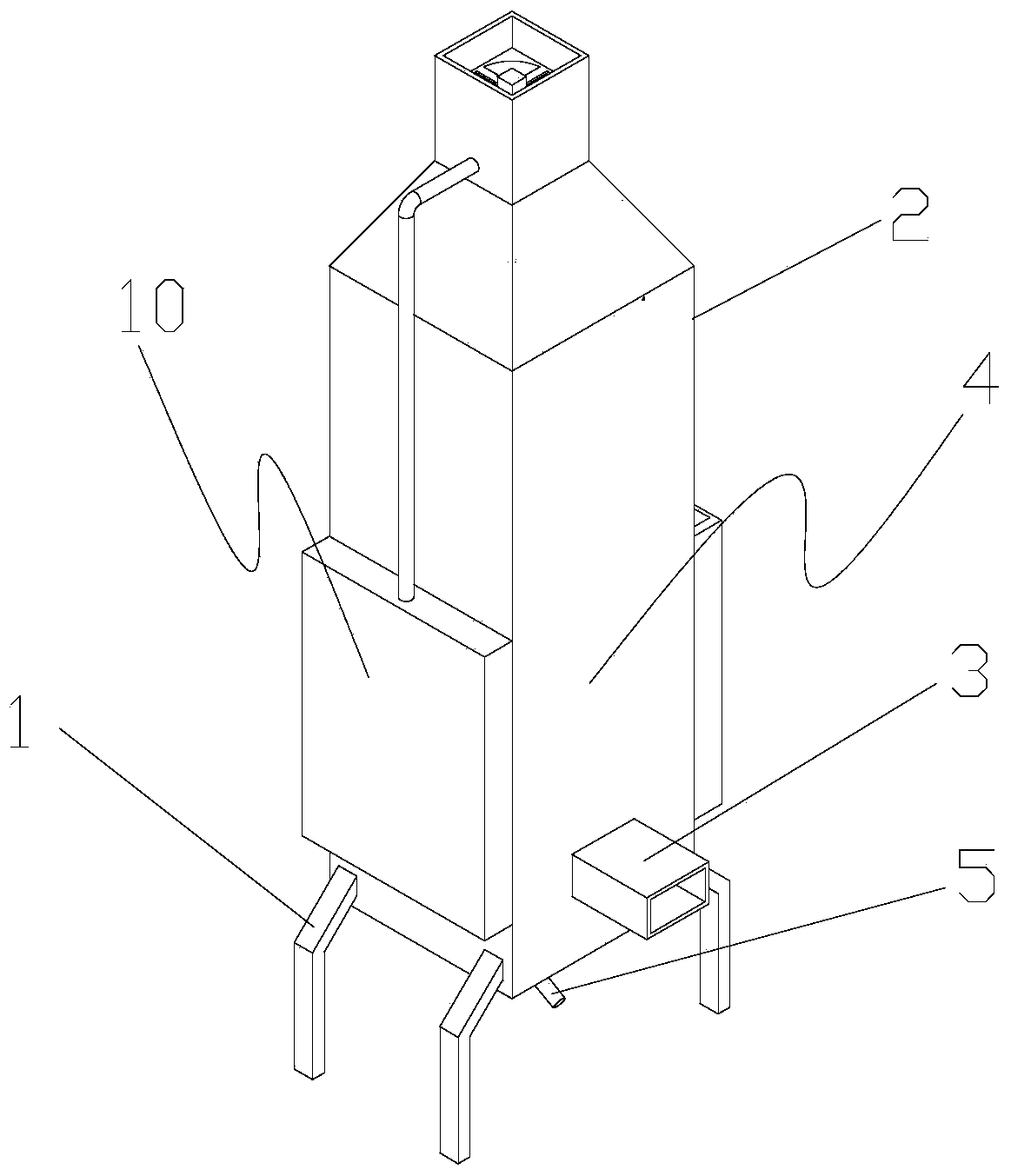

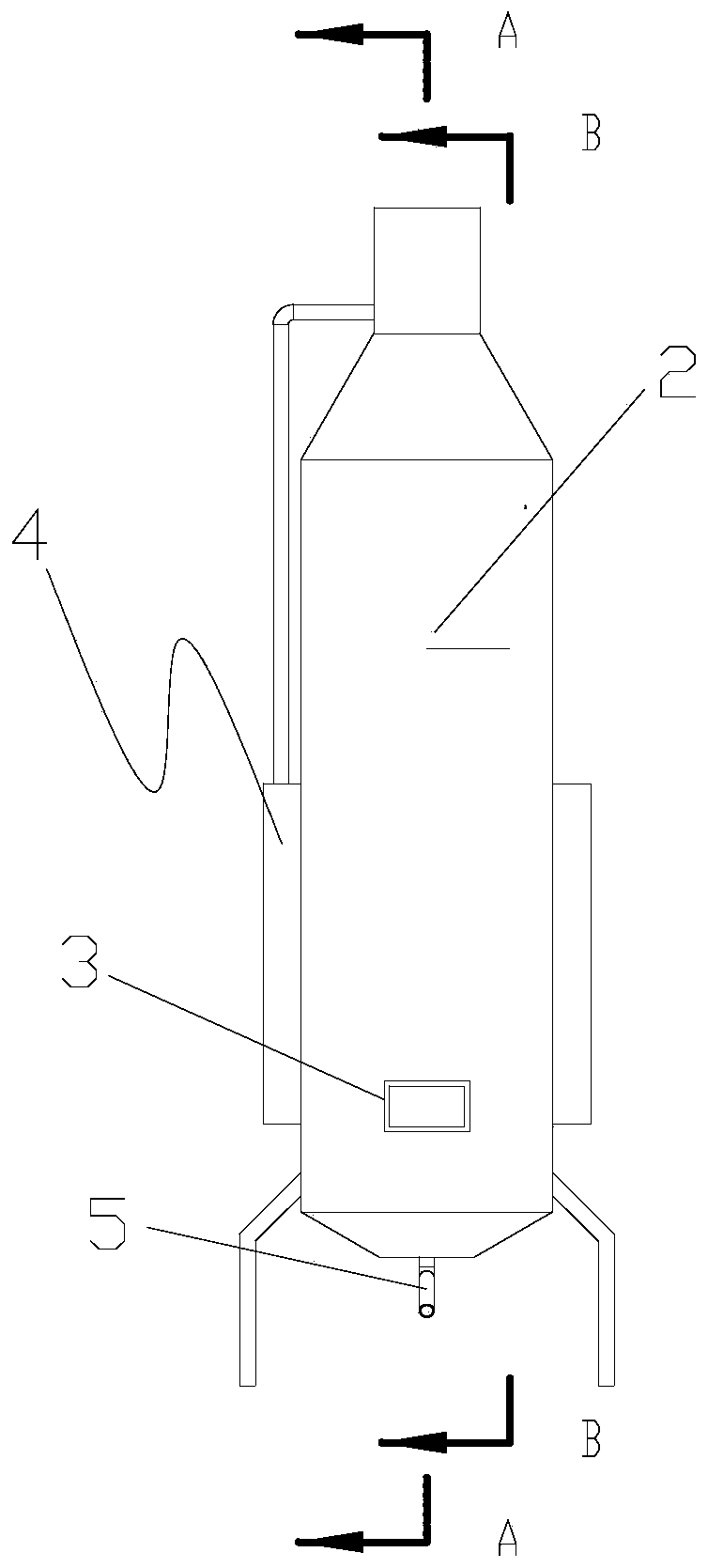

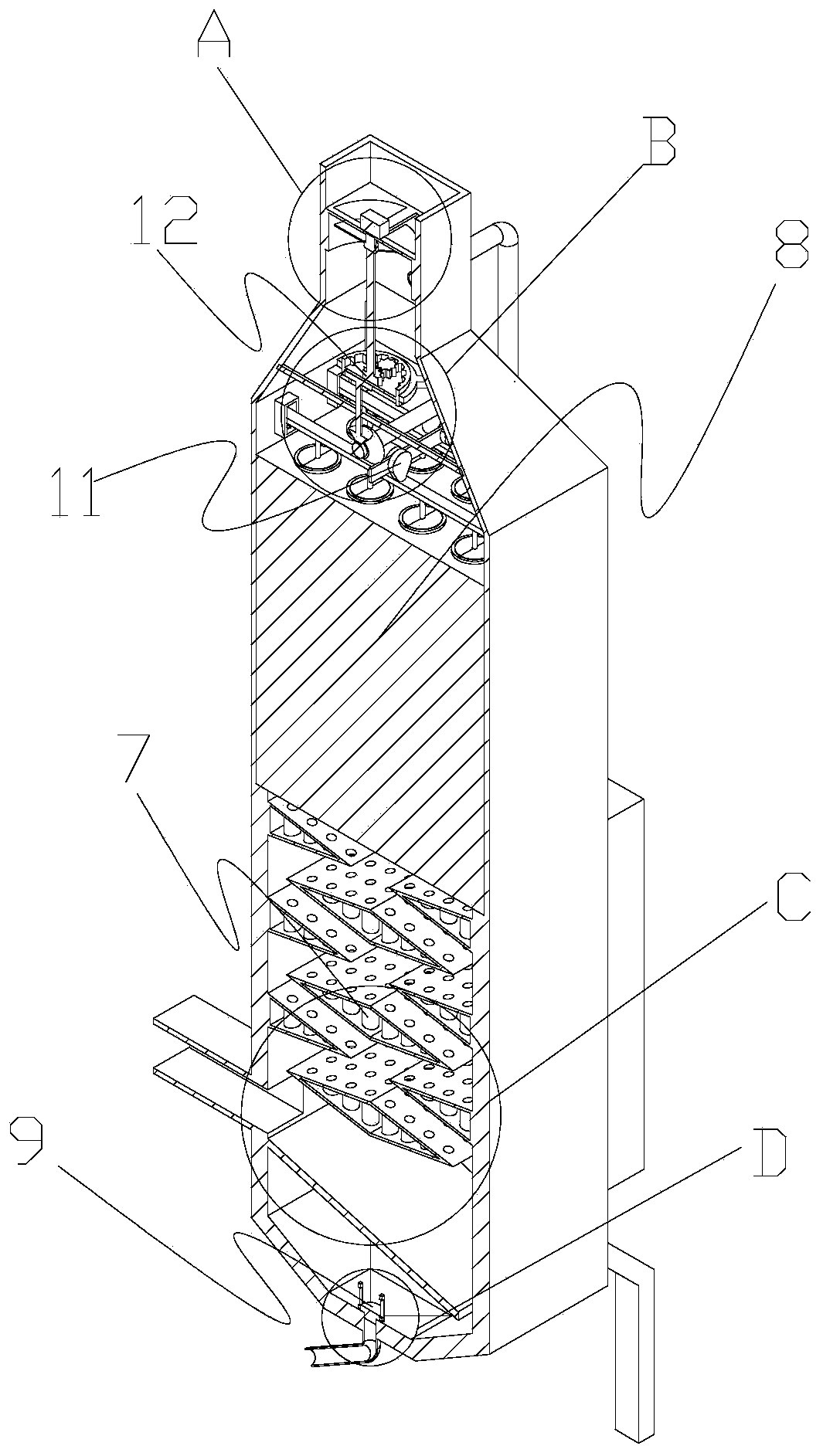

[0032] Such as Figure 1-17 As shown, an integrated oil mist purifier based on environmental engineering, the integrated oil mist purifier includes a first bracket 1, a housing 2, an air inlet 3, an oil purification device 4, and an oil discharge pipe 5; The body 2 is arranged on the first bracket, the air inlet 3 is arranged at the bottom of the side wall of the housing, the air inlet is arranged at the position below the side wall of the housing, the oil purification device 4 is arranged in the housing, and the exhaust The oil pipeline 5 is arranged at the bottom of the housing; the oil mist purification device 4 includes a second bracket 41, a motor 42, a fan blade 43, a primary purification chamber 7, a secondary purification chamber 8, and an oil discharge structure 9; The bracket 41 is located above the housing, and the second bracket is a cross-shaped structure for supporting the motor with good air permeability. The motor 42 is located on the second bracket, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com