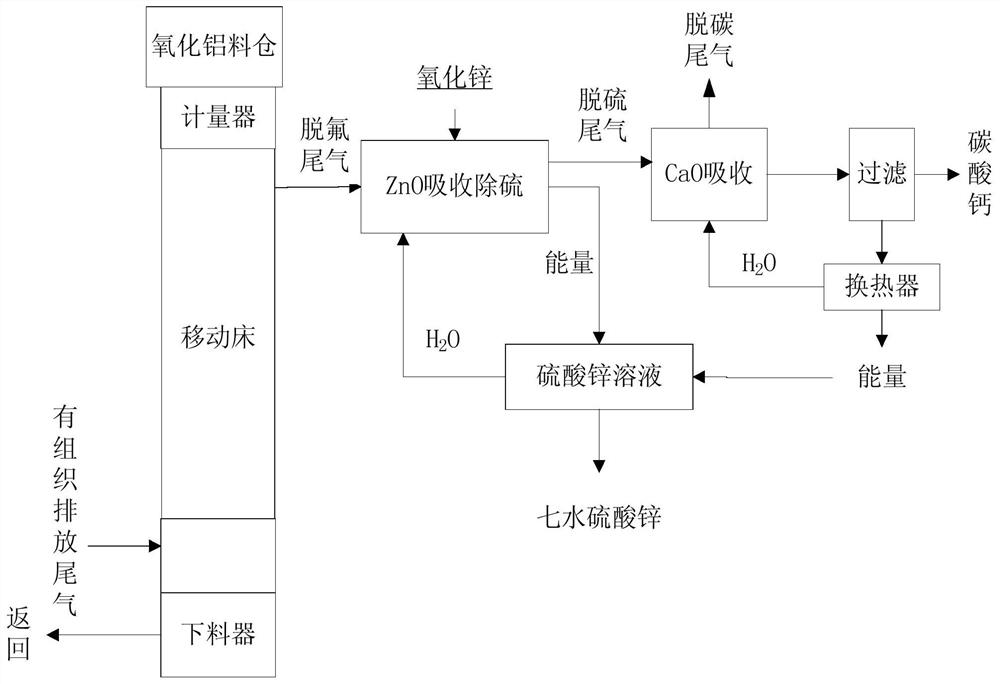

A deep purification method for organized tail gas discharge during aluminum electrolysis production process

A production process and deep purification technology, applied in chemical instruments and methods, separation methods, products, etc., to reduce carbon emissions, have considerable economic value, and improve the effect of defluorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

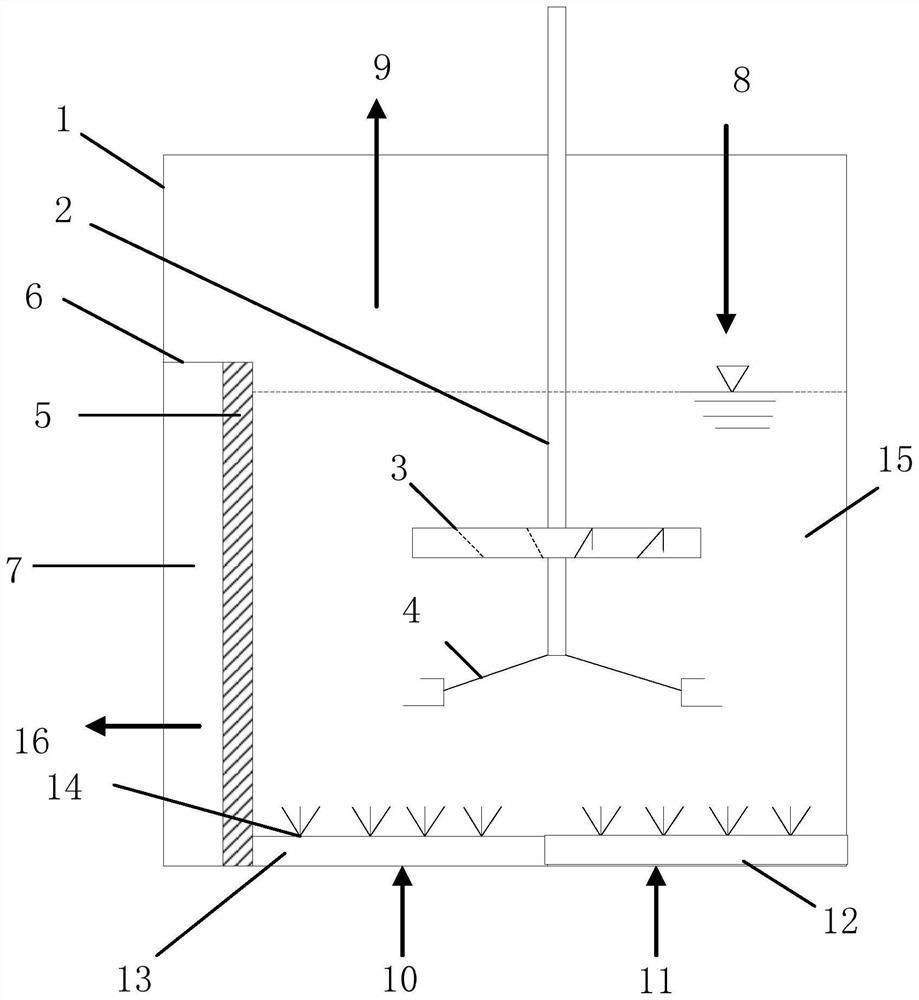

Method used

Image

Examples

Embodiment 1

[0044] The concentration of HF in the organized exhaust gas is 1.2mg / Nm 3 , SO 2 The concentration is 1000mg / Nm 3 , CO 2 The concentration is 8000mg / Nm 3 ;

[0045] The organized exhaust gas is passed into the moving bed equipped with γ-alumina, and the deep defluorination is carried out through the γ-alumina, and the defluorinated tail gas is formed after the deep defluorination; the organized exhaust gas enters from the lower part of the moving bed and flows upward , γ-alumina moves from top to bottom in the moving bed, the flow rate of the exhaust gas is controlled to be 3m / s, the moving speed of γ-alumina is 0.04m / h, and the solid-gas ratio is 25g / m 3 ; The solid-gas ratio refers to the weight of γ-alumina to the volume ratio of the organized exhaust gas;

[0046] HF concentration in defluorinated tail gas 3 ;

[0047] Inject the defluorinated tail gas and ozone into the desulfurization reactor equipped with zinc oxide slurry at the same time. The zinc oxide slurry i...

Embodiment 2

[0055] Method is with embodiment 1, and difference is:

[0056] (1) The concentration of HF in the organized exhaust exhaust gas is 2.1mg / Nm 3 , SO 2 The concentration is 780mg / Nm 3 , CO 2 The concentration is 9000mg / Nm 3 ;

[0057] (2) γ-alumina moves from top to bottom in the moving bed, the flow rate of the exhaust gas is controlled to be 2m / s, the moving speed of γ-alumina is 0.03m / h, and the solid-gas ratio is 28g / m 3 ;

[0058] (3) Desulfurization reactor initial condition Zinc oxide accounts for 18% of water gross weight; When the concentration of the zinc sulfate solution in the reaction tank reaches 260g / L, 1 / 3 of all zinc sulfate solution in the reactor is discharged;

[0059] (4) SO in desulfurization tail gas 2 The concentration of 12mg / Nm 3 ;

[0060] (5) Lower the temperature to 25±1°C for 20 minutes in a water bath, and dry the crystalline solid phase obtained by filtration at 45°C;

[0061] (6) The calcium ion concentration of the calcium ion-containi...

Embodiment 3

[0063] Method is with embodiment 1, and difference is:

[0064] (1) The concentration of HF in the organized exhaust gas is 3.3mg / Nm 3 , SO 2 The concentration is 590mg / Nm 3 , CO 2 The concentration is 10000mg / Nm 3 ;

[0065] (2) γ-alumina moves from top to bottom in the moving bed, the flow rate of the exhaust gas is controlled to be 1m / s, the moving speed of γ-alumina is 0.02m / h, and the solid-gas ratio is 32g / m 3 ;

[0066] (3) Desulfurization reactor initial condition Zinc oxide accounts for 15% of water gross weight; When the concentration of the zinc sulfate solution in the reaction tank reaches 220g / L, 1 / 3 of all zinc sulfate solution in the reactor is discharged;

[0067] (4) SO in desulfurization tail gas 2 The concentration of 10mg / Nm 3 ;

[0068] (5) Lower the temperature to 25±1°C for 30 minutes in a water bath, and dry the crystalline solid phase obtained by filtration at 45°C;

[0069] (6) The calcium ion concentration of the calcium ion-containing solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com