A microwave catalysis-biochemical vocs emission reduction combined equipment

A technology of microwave catalysis and combined equipment, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as secondary pollution, and achieve the effects of no secondary pollution, high purification efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

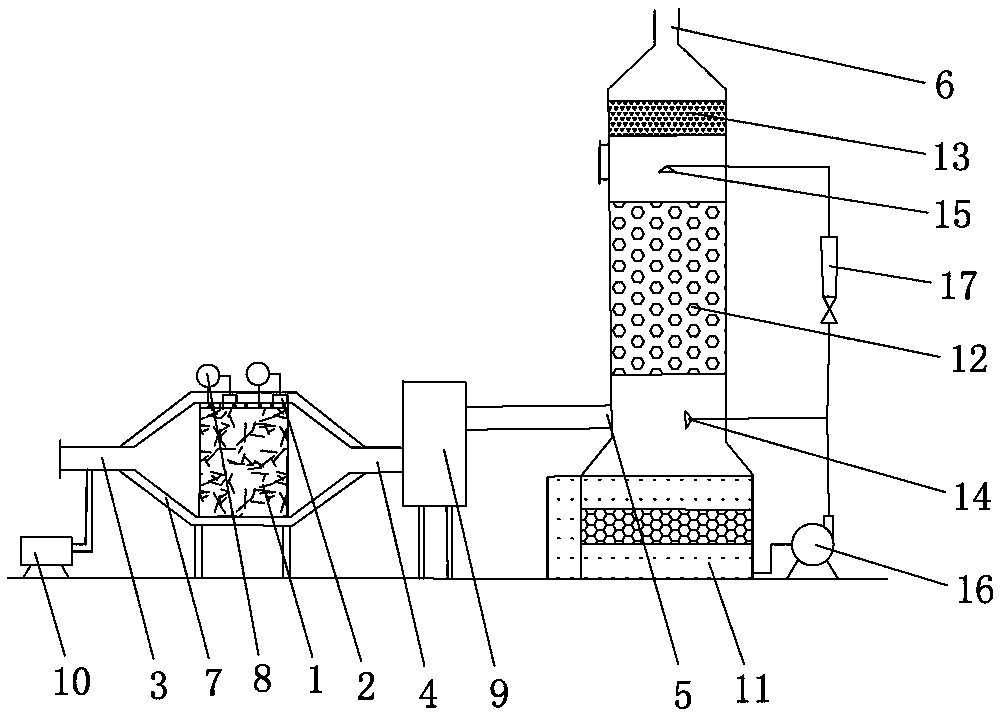

[0035] See figure 1 , a combination of microwave catalysis-biochemical VOCs emission reduction equipment, including a microwave catalysis reaction device and a biochemical reactor arranged in sequence, the microwave catalysis reaction device includes a catalyst layer 1 arranged inside it for exhaust gas to pass through, for heating The microwave launcher 2 of the catalyst layer 1, the catalytic air inlet 3 for the exhaust gas to enter the microwave catalytic reaction device, and the catalytic exhaust port 4 for the exhaust gas to flow out. The biochemical reactor is provided with a biological purification mechanism. There is a biochemical air inlet 5 connected with the catalytic exhaust port 4 and a biochemical air outlet 6 for gas to flow out.

[0036] Wherein, the microwave catalytic reaction device further includes a resonant cavity 7, and the size of the circular section of the resonant cavity 7 gradually decreases from the middle to both ends.

[0037] Wherein, the catal...

Embodiment 2

[0057] See figure 1 , the difference between this embodiment and embodiment 1 is:

[0058] Wherein, the solid catalyst used in the catalyst layer 1 is a mixture of metal oxide, silicon carbide and three-dimensional graphene with a mass ratio of 2:1:2; the metal oxide is an oxide of cobalt, copper, iron, nickel A mixture composed of a mass ratio of 1:2:2:1.

[0059] Wherein, the oxidizing agent adding device 10 of this embodiment does not add an oxidizing agent.

[0060] Wherein, the eluted bacterial layer is a mixed colony layer composed of Pseudomonas putida, Bacillus and Staphylococcus with a colony density ratio of 2:2.5:3.

[0061] Wherein, the drip filter layer is a mixed colony layer composed of the genus Leather, Trichoderma and Paecilomyces with a colony density ratio of 1:2:3.

[0062] Wherein, the third attachment filler is a hydrophilic sponge loaded with graphene and having far-infrared radiation and magnetism.

[0063] Wherein, the filter bacteria layer is a m...

Embodiment 3

[0068] See figure 1 , the difference between this embodiment and embodiment 1 is:

[0069]Wherein, the solid catalyst used in the catalyst layer 1 is a mixture of metal oxide, silicon carbide and three-dimensional graphene with a mass ratio of 2:3:5; the metal oxide is an oxide of cobalt, copper, iron, nickel A mixture composed of a mass ratio of 1:3:5:1.

[0070] Wherein, the oxidizing agent adding device 10 of this embodiment does not add an oxidizing agent.

[0071] Wherein, the elution bacteria layer is a mixed colony layer composed of Pseudomonas putida, Bacillus and Staphylococcus with a colony density ratio of 2:3:4.

[0072] Wherein, the trickle-filtered bacteria layer is a mixed colony layer composed of the genus Leather, Trichoderma and Paecilomyces with a colony density ratio of 1:3:4.

[0073] Wherein, the filter bacteria layer is a mixed colony layer composed of Paecilomyces, Mucor, Trametes and Burkholderia with a colony density ratio of 1:2:3.

[0074] Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com