Electrode material for supercapacitor and preparation method and application thereof

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of agglomeration, unfavorable use of supercapacitor materials, and high cost, and achieve the effects of low resistivity, multiple reactive sites, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

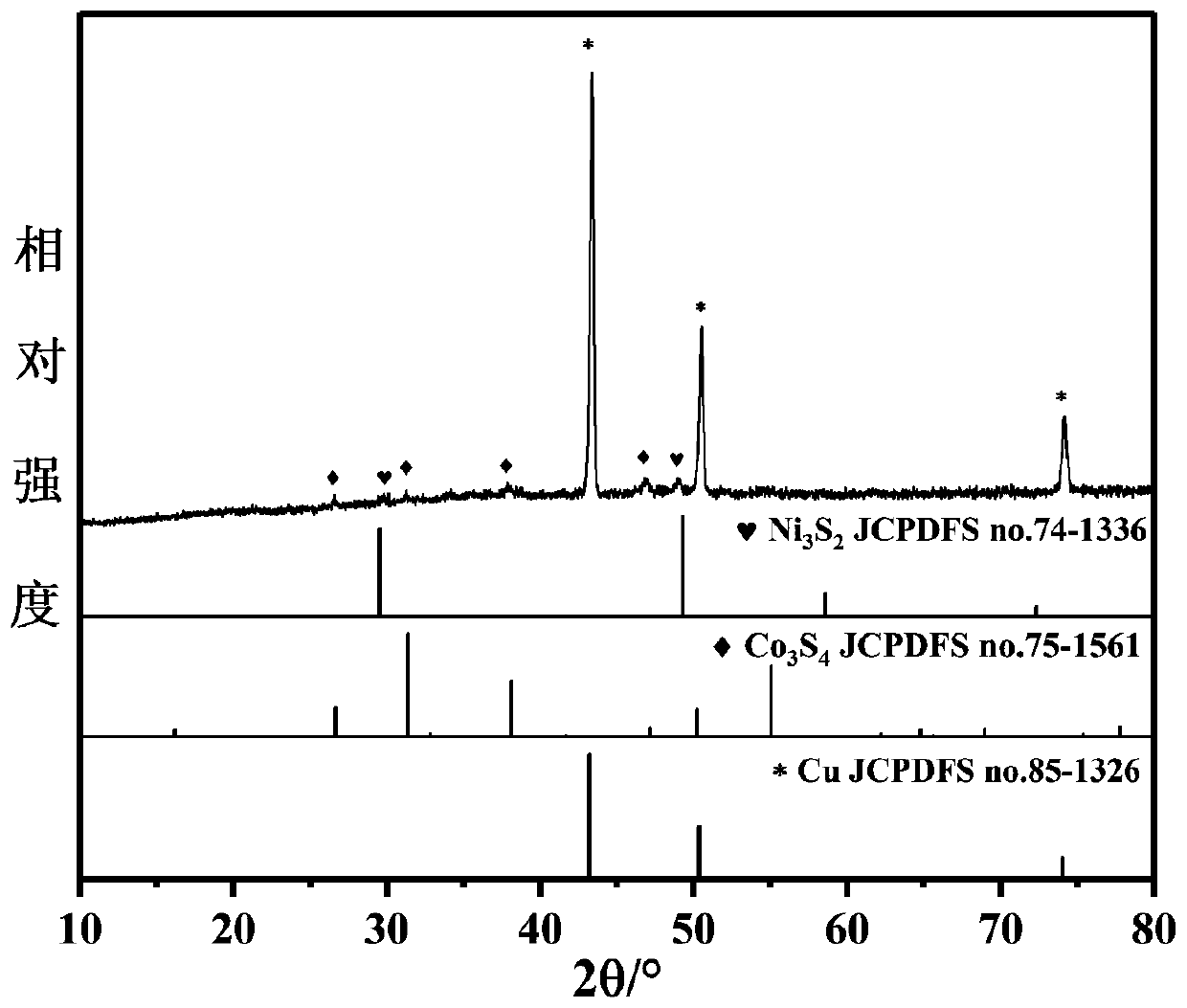

[0038] A method for preparing electrode materials for supercapacitors includes the following steps:

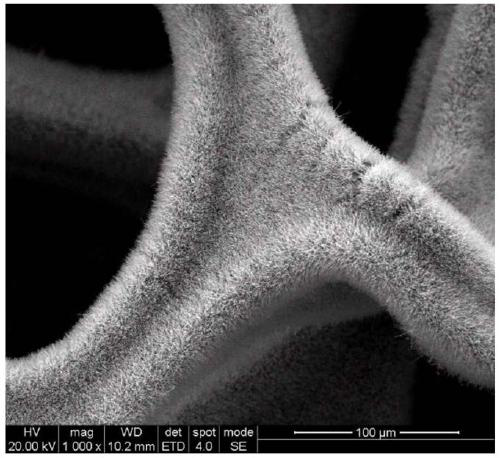

[0039] (1) Pretreatment of foamed copper: Cut the foamed copper into 1cm*3cm, put the foamed copper into 1mol / L hydrochloric acid and sonicate for 10 minutes, take it out and wash it with deionized water several times, and then put it in acetone for 3 minutes of sonication. Finally, the foamed copper was sonicated 2-3 times with absolute ethanol and deionized water, and dried in a vacuum drying oven at 50°C;

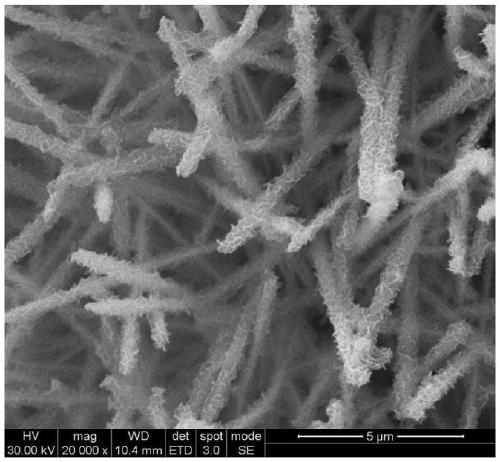

[0040] (2) Put the pretreated foamed copper in a uniform mixed solution of 16mL of sodium hydroxide (10mol / L) and 44mL of ammonium persulfate (0.9mol / L), react for 20 minutes, and then use anhydrous ethanol and Deionized water was sonicated for 2-3 times and dried in a drying box at 50°C to obtain a copper hydroxide nanowire precursor material based on foamed copper.

[0041] (3) Place the prepared copper hydroxide nanowire precursor based on foamed copper in a mixed solution ...

Embodiment 2

[0050] A method for preparing electrode materials for supercapacitors includes the following steps:

[0051] (1) Pretreatment of foamed copper: Cut the foamed copper into 3cm*4cm, put the foamed copper into 1mol / L hydrochloric acid and sonicate for 10 minutes, take it out and wash it with deionized water several times, and then put it in acetone and sonicate for 3 minutes. Finally, the foamed copper was sonicated 2-3 times with absolute ethanol and deionized water, and dried in a vacuum drying oven at 50°C;

[0052] (2) Put the pretreated foamed copper in a homogeneous mixed solution of 16mL of sodium hydroxide (10mol / L) and 44mL of ammonium persulfate (0.9mol / L), react for 20 minutes, and then use absolute ethanol. Ultrasound with deionized water for 2-3 times, and dry in a drying box at 50°C to obtain a copper hydroxide nanowire precursor material based on foamed copper.

[0053] (3) Place the prepared copper hydroxide nanowire precursor based on foamed copper in a mixed solution ...

Embodiment 3

[0056] A method for preparing electrode materials for supercapacitors includes the following steps:

[0057] (1) Pretreatment of foamed copper: Cut the foamed copper into 1cm*3cm, put the foamed copper into 1mol / L hydrochloric acid and sonicate for 10 minutes, take it out and wash it with deionized water several times, and then put it in acetone for 3 minutes of sonication. Finally, the foamed copper was sonicated 2-3 times with absolute ethanol and deionized water, and dried in a vacuum drying oven at 50°C;

[0058] (2) Place the pretreated foamed copper in a homogeneous mixed solution of 16mL of sodium hydroxide (10mol / L) and 44mL of ammonium persulfate (0.9mol / L), react for 20 minutes, and then use anhydrous ethanol and Deionized water was sonicated for 2-3 times and dried in a drying box at 50°C to obtain a copper hydroxide nanowire precursor material based on foamed copper.

[0059] (3) Place the prepared copper hydroxide nanowire precursor based on foamed copper in a mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com