Waste activated carbon and waste organic solvent synergistic harmless resource utilization and disposal method

A technology of organic solvents and disposal methods, applied in the field of waste treatment and resource utilization, can solve problems such as escape and environmental pollution, and achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for synergistic and harmless resource utilization and disposal of waste activated carbon and waste organic solvent, comprising the following steps:

[0056] (1) Preparation of sodium lignosulfonate: Add lye dropwise to sulfite pulping waste liquor, adjust the pH of the mixture to 10; react at 90°C for 2 hours, filter, concentrate the filtrate, cool and crystallize, that is Obtain sodium lignosulfonate;

[0057] (2) Send the waste activated carbon and petroleum spirit waste organic solvents produced in the electroplating industry to the ball mill at a mass ratio of 100:100, add water or industrial wastewater to a solid content of 51wt%, and grind them into powder with a viscosity of 400mPa.s Activated carbon slurry in organic solvent;

[0058] (3) Send the activated carbon slurry of the organic solvent obtained in step (2), coal, and sodium lignosulfonate obtained in step (1) to a rod mill at a mass ratio of 50:1:0.005, add water or Industrial wastewater to a ...

Embodiment 2

[0062] A method for synergistic and harmless resource utilization and disposal of waste activated carbon and waste organic solvent, comprising the following steps:

[0063] (1) Send the waste activated carbon and waste organic solvent produced in the aspirin production process to the ball mill at a mass ratio of 100:150, add water or industrial waste water to a solid content of 41wt%, and grind it into powder with a viscosity of 300mPa.s Activated carbon slurry in organic solvents;

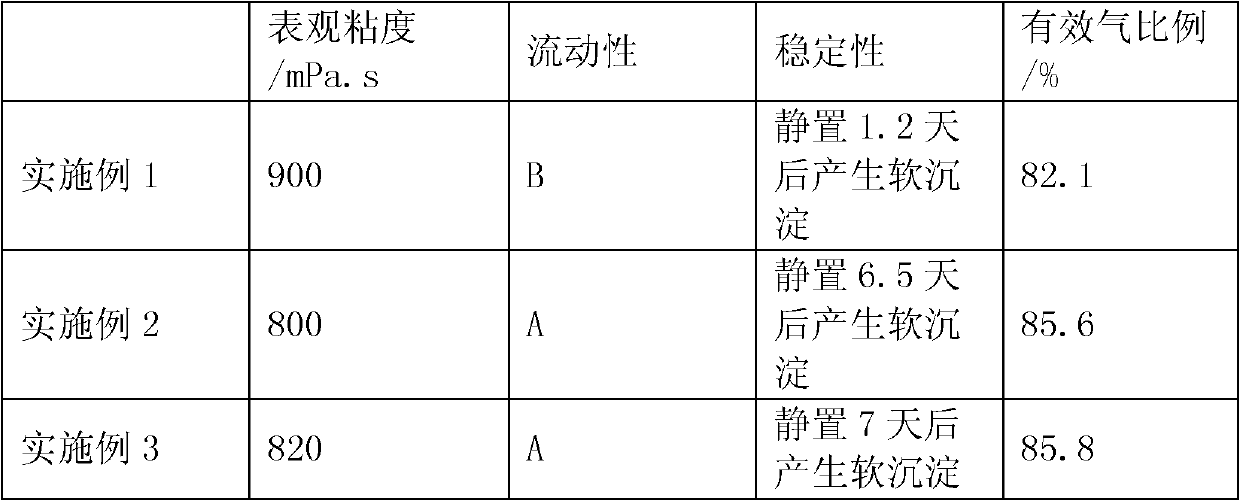

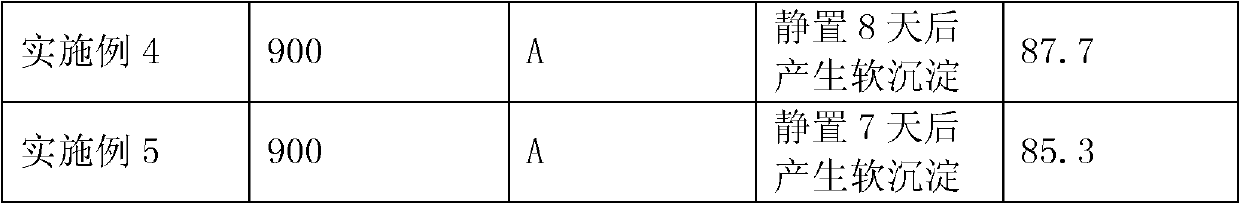

[0064] (2) Send the activated carbon slurry of the organic solvent obtained in step (1), coal, and sodium naphthalenesulfonate formaldehyde condensate to the rod mill at a mass ratio of 20:1:0.004, and add water or industrial wastewater to the solid content 60wt%, ground into a multi-source synthetic slurry with a viscosity of 800mPa.s (i.e. coal water slurry);

[0065] (3) Send the multi-source synthetic slurry obtained in step (2) into the coal-water slurry gasifier together with oxygen, and re...

Embodiment 3

[0068] A method for synergistic and harmless resource utilization and disposal of waste activated carbon and waste organic solvent, comprising the following steps:

[0069] (1) Send the waste activated carbon produced in the ink production process and the waste organic solvent produced in the wood coating process to the ball mill at a mass ratio of 100:200, add water or industrial waste water to a solid content of 35wt%, and grind the powder Make the active carbon slurry of the organic solvent that viscosity is 330mPa.s;

[0070] (2) Send the activated carbon slurry, coal, and sodium polycarboxylate in the organic solvent obtained in step (1) to a rod mill at a mass ratio of 1:1:0.003, and add water or industrial waste water to a solid content of 58wt% , ground into a multi-source synthetic slurry (ie, coal water slurry) with a viscosity of 820mPa.s; the above-mentioned sodium polycarboxylate is a copolymer of methacrylic acid and sodium acrylate;

[0071] (3) Send the multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com