Environment-friendly oil spill dispersant and preparation method thereof

An oil spill dispersant, an environmentally friendly technology, applied in the field of emergency response to oil spill pollution, can solve the problems of low safety and high toxicity, achieve efficient removal, easy biodegradation, and reduce secondary pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

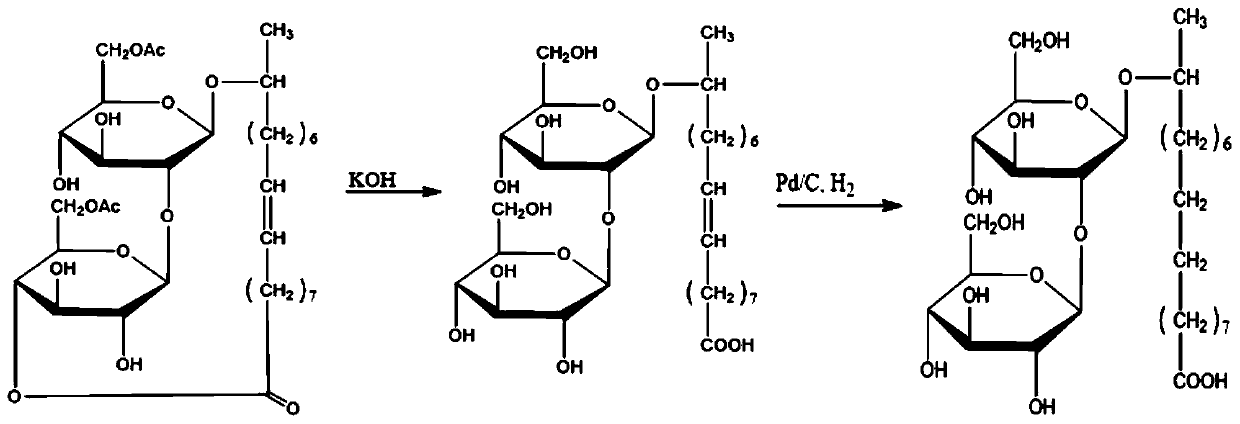

[0023] (1) Put 50Kg of sophorolides in a 500L glass reactor, add 100L of water and 160L of ethanol in turn, stir to form a homogeneous phase, add 1mol / L potassium hydroxide solution to adjust the pH value of the reaction solution to 9-10, at room temperature Stir for 1h, then neutralize with 1mol / L sulfuric acid, filter to remove the precipitate; add Pd / C catalyst to the filtrate, and react for 24h under the protection of hydrogen; then filter to remove Pd / C, and distill off the solvent under reduced pressure to obtain deacetylated acid sophorolipids (such as figure 1 shown).

[0024] (2) In a 100L reactor, add 50L of water as a solvent and heat to keep the temperature of the reactor at 30°C; then add 20% rhamnolipid by mass and stir to dissolve; then add Than 10% deacetylated acidic sophorolipids, stirring and dissolving; then adding mass proportions of 5% sophorolipids and mass proportions of 15% alkyl glycosides, stirring and dissolving; adjusting the pH to Between 7.5 an...

Embodiment 2

[0027] (1) Put 40Kg of sophorolides in a 500L glass reactor, add 80L of water and 140L of ethanol in turn, stir to form a homogeneous phase, add 1mol / L potassium hydroxide solution to adjust the pH value of the reaction solution to 9-10, at room temperature Stir for 1h, then neutralize with 1mol / L dilute hydrochloric acid solution, filter to remove the precipitate; add Pd / C catalyst to the filtrate, and react for 24h under the protection of hydrogen; then filter to remove Pd / C, and distill off the solvent under reduced pressure to obtain Acetylated acid sophorolipids.

[0028] (2) In a 100L reactor, add 75L of water as a solvent and heat to keep the temperature of the reactor at 40°C; then add 10% rhamnolipid by mass and stir to dissolve; then add than 5% deacetylated acidic sophorolipids, stirring and dissolving; then adding mass proportions of 2% sophorolipids and mass proportions of 8% alkyl glycosides, stirring and dissolving; adjusting the pH to Between 7.0 and 7.5, the ...

Embodiment 3

[0031] (1) Put 30Kg of sophorolides in a 500L glass reactor, add 60L of water and 120L of ethanol in turn, stir to form a homogeneous phase, add 0.5mol / L potassium hydroxide solution to adjust the pH value of the reaction solution to 9-10, room temperature Stir for 1 h, then neutralize with 0.5 mol / L dilute sulfuric acid solution, filter to remove the precipitate; add Pd / C catalyst to the filtrate, and react for 24 h under the protection of hydrogen; then filter to remove Pd / C, and remove the solvent by distillation under reduced pressure. Deacetylated acid sophorolipids are obtained.

[0032] (2) In a 100L reaction kettle, add 80L of water as a solvent and heat to keep the temperature of the reaction kettle at 50°C; then add rhamnolipid with a mass ratio of 5% and stir to dissolve; then add than 5% deacetylated acidic sophorolipids, stirring and dissolving; then adding mass proportions of 3% sophorolipids and mass proportions of 7% alkyl glycosides, stirring and dissolving; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com