Method for preparing bionic bait from polymer insulating resin composite material

An insulating resin and composite material technology, which is applied in artificial fishing bait, fishing, application, etc., can solve the problems of not being able to simulate the living state of small fish well, the purpose of bionics cannot be achieved, and affecting the attraction of big fish, etc. The bionic effect is poor, the service life is improved, and the self-lubricating effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

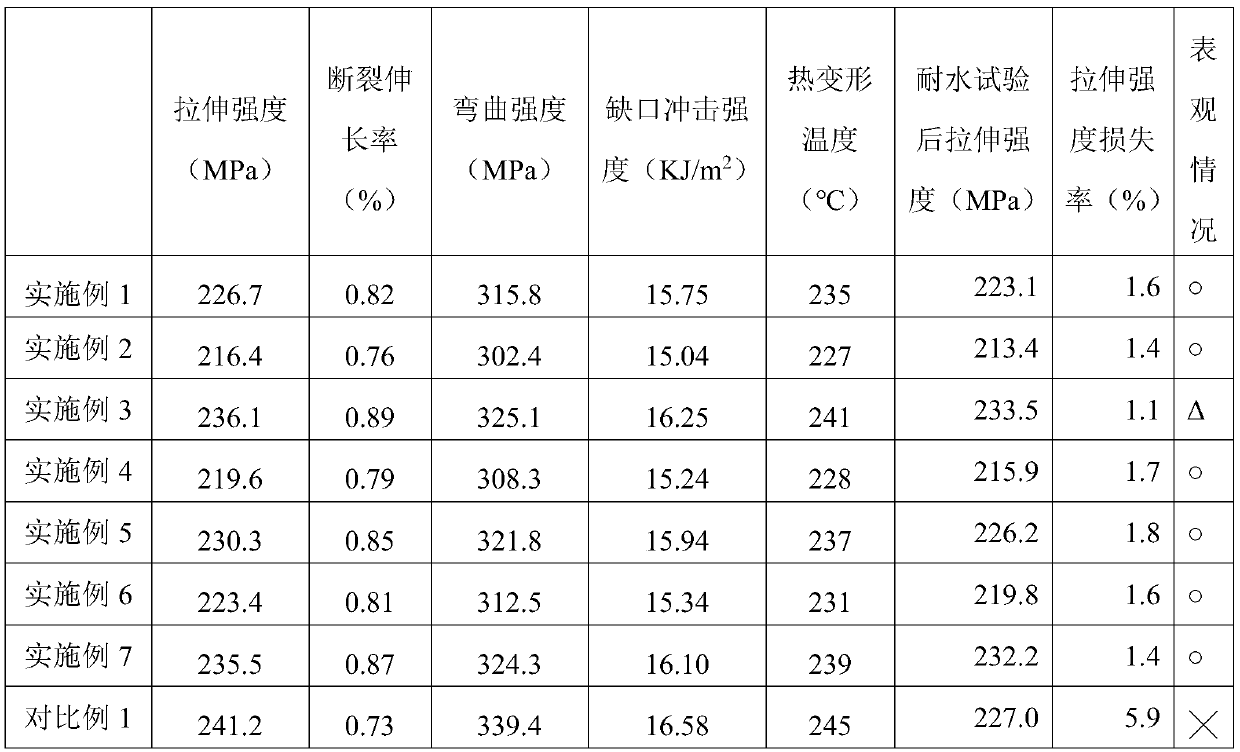

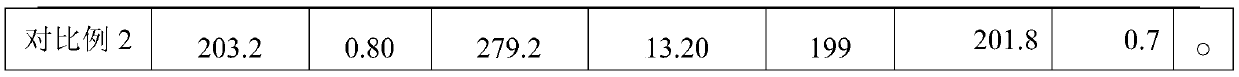

Examples

Embodiment 1

[0038] A method for preparing a bionic bait by using a polymer insulating resin composite material, comprising the following steps:

[0039] (1) First put the nylon 6 resin raw material (CM1021FS purchased from Toray, Japan, with a relative viscosity of 3.4Pa·S (the test solvent is concentrated sulfuric acid with a mass fraction of 95%)) in an oven, and dry it at a temperature of 80°C Treat for 5 hours, take it out and add the glass fiber after refinement treatment, silane coupling agent KH550 and antioxidant into the high mixer, stir and mix at high speed for 3 minutes; then melt, mix and extrude through a twin-screw extruder, Water cooling, pelletizing and drying after stripping to obtain mixture M;

[0040] Wherein, the length of the glass fiber after the thinning treatment is 5 μm;

[0041] The weight ratio of the nylon 6, glass fiber, silane coupling agent KH550 and antioxidant is 1:0.06:0.02:0.04;

[0042]The temperature of the heating section of the twin-screw extrude...

Embodiment 2

[0048] This example is basically the same as the method for preparing the bionic bait in Example 1, except that in step (1), the length of the glass fiber after the thinning treatment is 3 μm; bionic bait.

Embodiment 3

[0050] This example is basically the same as the method for preparing the bionic bait in Example 1, the difference is that in step (1), the length of the glass fiber after the thinning treatment is 8 μm; bionic bait.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com