Modified lignin enhanced rubber and preparation method thereof

A lignin and enhanced technology, applied in the field of rubber, can solve the problems of affecting rubber performance, high energy consumption, uneven particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: the preparation of modified lignin (dipping method)

[0069] Weigh the carbon-carbon double bond-containing compound and the sulfur-containing compound according to Table 1, stir and mix, add ethanol to it, the concentration of the carbon-carbon double bond-containing compound and the sulfur-containing compound are both 2g / mL, to obtain The first solution; according to Table 1, take the compound that can block the hydroxyl group, add ethanol therein, and the concentration of this substance is 2g / mL to obtain the second solution; if the compound containing carbon-carbon double bonds in Table 1 and the sulfur-containing element Compounds and compounds that can block hydroxyl groups do not need to be dissolved in ethanol, and can be used directly, and the consumption of these compounds is controlled according to the description of the following two paragraphs.

[0070] The first solution was added dropwise to 10 g of enzymatic lignin (the amount of carbon-car...

Embodiment 2

[0082] Embodiment 2: the preparation of modified lignin (air flow modification method)

[0083] According to numbers 4, 9, 10 and 12 in Table 1, the first solution and the second solution were prepared according to the same method as in Example 1.

[0084]Spray enzymatic lignin into the crushing chamber through high-pressure air at about 100°C, and at the same time, spray the first solution (flow rate of 40mL / min) into the crushing chamber through the atomizing nozzle, and the speed of the air classification wheel is 2000rpm , run for 2min; then spray the second solution (flow rate of 40mL / min) into the pulverization chamber through the atomizing nozzle, the speed of the air classification wheel is 2000rpm, run for 3min; and then separate through the cyclone separator to obtain four kinds of modified Lignin, namely ligni4, lignin9, lignin10, lignin12. The D50 of the three were 1.6 μm, 1.4 μm, 1.7 μm and 2.3 μm, respectively, through the particle size test of the US-based Mact...

Embodiment 3

[0085] Embodiment 3: Preparation of lignin-reinforced rubber

[0086] (1) Take 10g of enzymatic lignin (particle size has been air-pulverized to 2.1 μm) and the lignin4, lignin9, lignin10, lignin12, lignin13, lignin14 prepared in Example 2, 40g of natural rubber, and 10g of high wear-resistant carbon black N330 , 1g of sulfur, 0.6g of N-cyclohexyl-2-benzothiazole sulfenamide, 2g of zinc oxide and 0.8g of stearic acid were sequentially added to the internal mixer, and banburyed at 100°C for 20 minutes;

[0087] (2) Place the mixed rubber obtained in step (1) in an open mill for 7 times of thin pass, and measure its vulcanization performance with a rubber vulcanizer to obtain the normal vulcanization time t at 180°C. 90 After 3 minutes, they were molded by hot pressing at 180°C for 3 minutes with a flat vulcanizer.

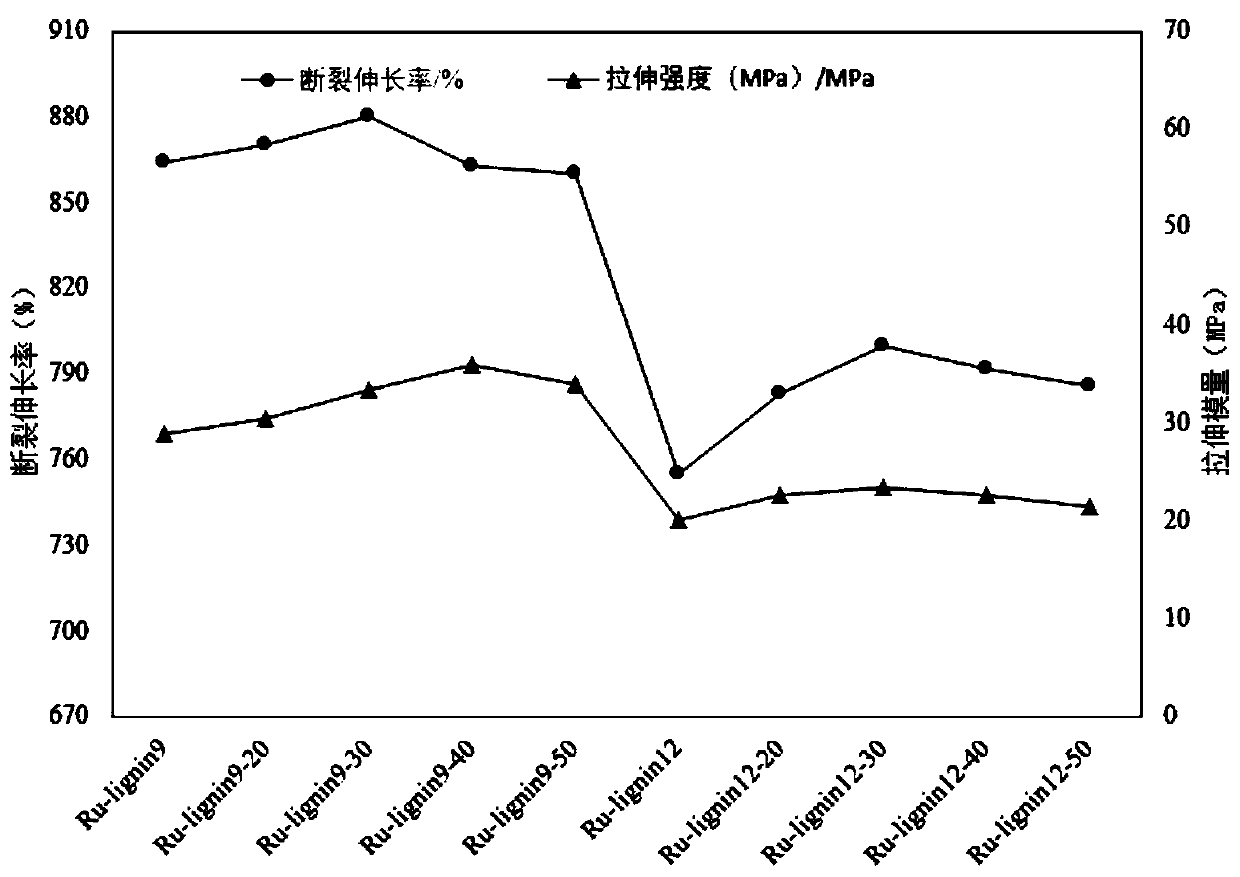

[0088] Table 3 Properties of vulcanized rubber

[0089]

[0090] It can be seen from Table 3 that in the case of the same particle size, compared with unmodifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com