Channelization continuous production process of polymethyltriethoxysilane

A technology of polymethyltriethoxysilane and monomethyltrichlorosilane, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problem of difficult prevention and control of material leakage, There are problems of explosion risk and high safety risk, so as to achieve the effect of improving production efficiency, uniform and stable product quality, and reducing safety risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 5

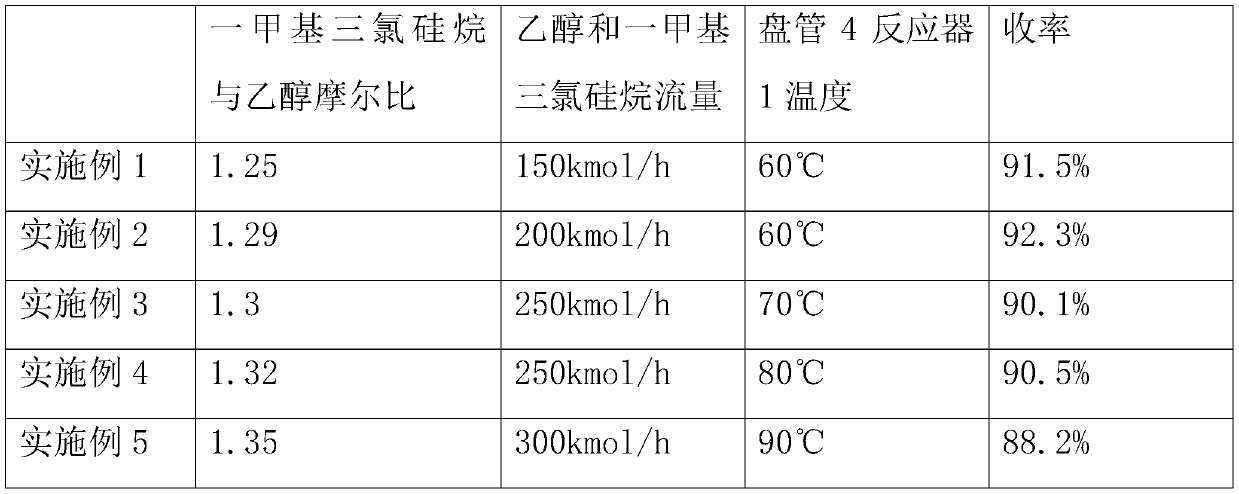

[0037] Polymethyltriethoxysilane was prepared by using the above-mentioned pipelined continuous production process steps of polymethyltriethoxysilane, and the product yield is shown in Table 1.

[0038] Table 1:

[0039]

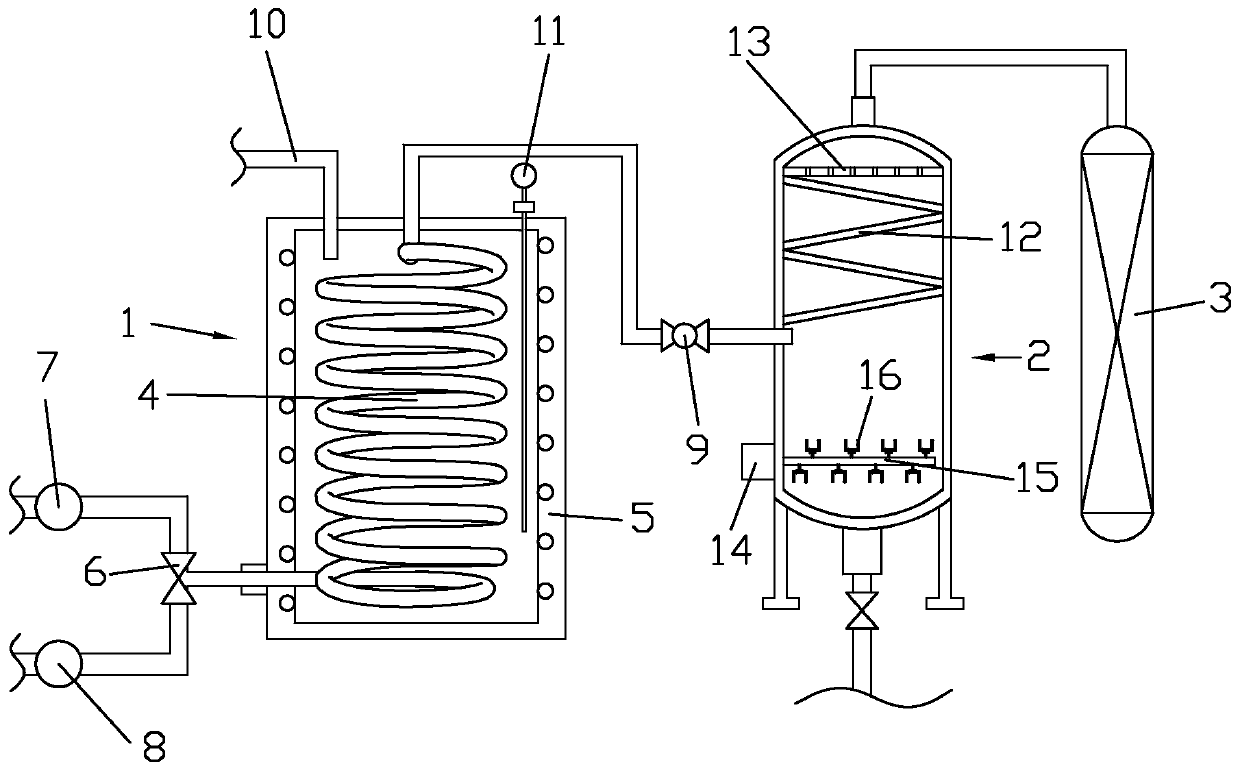

[0040] Ethanol and monomethyltrichlorosilane react instantaneously in reactor 1 of coil tube 4 to generate polymethyltriethoxysilane. Since the absolute amount of main raw materials used instantaneously is greatly reduced, safety risks are greatly reduced and production efficiency is greatly improved . The polymethyltriethoxysilane and hydrogen chloride gas generated by the reaction are separated through the gas-liquid separator 2, the hydrogen chloride gas escapes upwards, and the polymethyltriethoxysilane flows out from the bottom of the gas-liquid separator 2. The filler increases the resistance and plays the role of stirring ethanol and monomethyltrichlorosilane, so that the two can be fully mixed. Since hydrogen chloride gas is generated during the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com