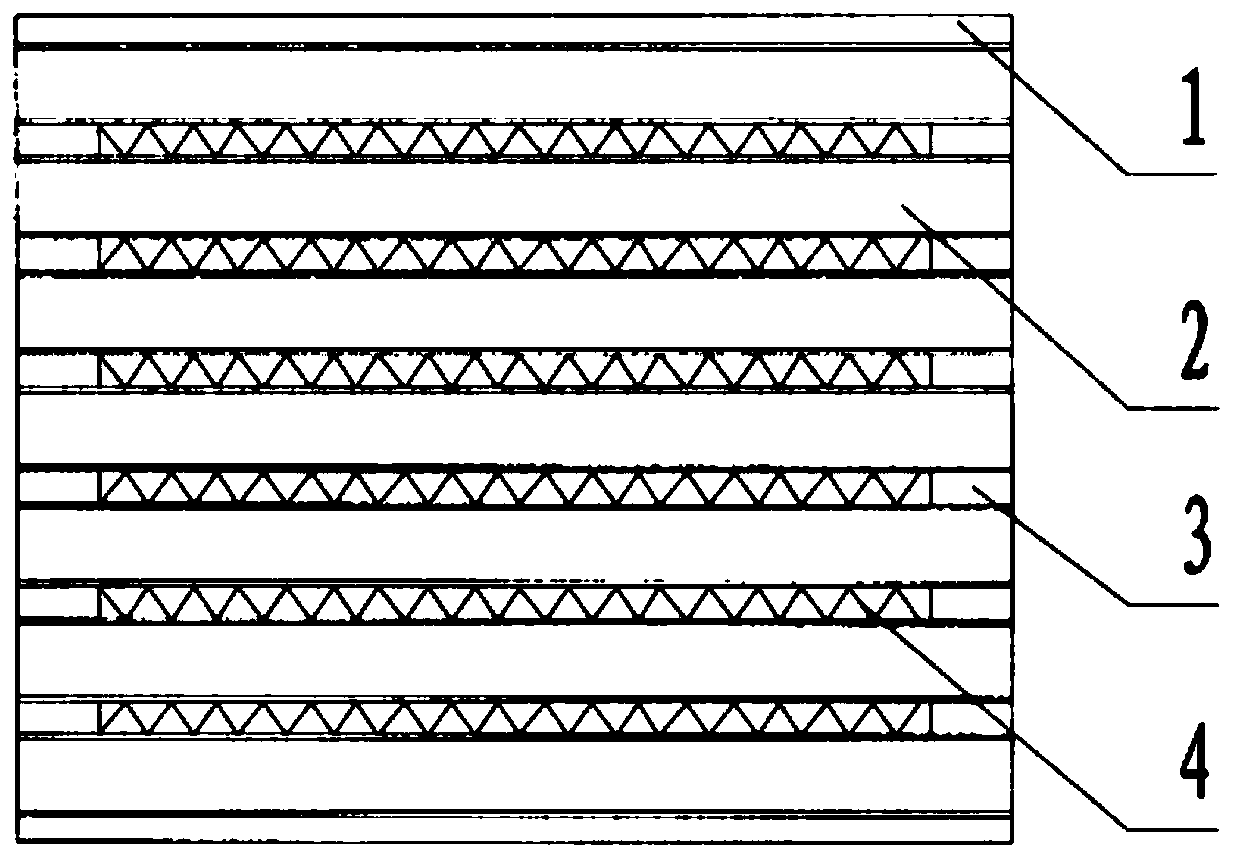

Stainless steel plate fin type radiator and processing method thereof

A stainless steel plate and processing method technology, applied in the field of mechanical processing, can solve the problems of easy deformation of fins, poor thermal stability of fins, easy damage of radiators, etc., and achieve the effect of ensuring normal operation, improving strength and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Take Fe: 85 parts, C: 0.05 parts, Si: 0.02 parts, Mn: 0.1 parts, S: 0.01 parts, Ni: 1 part, Cr: 15 parts, Cu: 0.1 parts, Al: 0.2 parts, Ti: 0.001 part, P: 0.01 part, Mg: 0.01 part, Nb: 0.01 part, W: 0.01 part and put them into a mixing container and mix evenly; put the mixed raw materials into a vacuum furnace for melting, specifically: mix Put the final raw material into a vacuum furnace and heat it to 1050°C, hold it for 12 hours and then remove the slag to remove impurities; after heat preservation, nitrogen gas is introduced and the furnace temperature is lowered to 850°C for 5 hours of refining; when the furnace temperature drops to 700°C, the molten iron is poured into the mold In the process, the bar is obtained after cooling and demoulding; the bar is drawn in an automatic wire drawing machine to obtain a steel wire with a diameter of 3mm; the steel wire is pressed into a strip steel wire with a thickness of 0.5mm and a width of 3mm through an automati...

Embodiment 2

[0034] Example 2: Fe: 100 parts, C: 0.1 parts, Si: 2 parts, Mn: 5 parts, S: 0.02 parts, Ni: 5 parts, Cr: 12 parts, Cu: 2 parts, Al: 3 parts, Ti: 0.005 parts, P: 0.05 parts, Mg: 0.1 parts, Nb: 0.3 parts, W: 0.1 parts and put them into a mixing container and mix evenly; put the mixed raw materials into a vacuum furnace for melting, specifically: mix Put the final raw material into a vacuum furnace and heat it up to 1250°C. After 14 hours of heat preservation, the slag is removed to remove impurities; after heat preservation, nitrogen gas is introduced and the furnace temperature is lowered to 900°C for 9 hours of refining; when the furnace temperature drops to 760°C, the molten iron is poured into the mold In the process, the bar is obtained after cooling and demoulding; the bar is drawn in an automatic wire drawing machine to obtain a steel wire with a diameter of 5mm; the steel wire is pressed into a strip steel wire with a thickness of 1mm and a width of 4mm through an automat...

Embodiment 3

[0035] Example 3: Fe: 90 parts, C: 0.06 parts, Si: 0.1 parts, Mn: 1.5 parts, S: 0.012 parts, Ni: 2 parts, Cr: 14.5 parts, Cu: 0.7 parts, Al: 0.6 parts, Ti: 0.002 parts, P: 0.02 parts, Mg: 0.03 parts, Nb: 0.05 parts, W: 0.04 parts and put them into a mixing container and mix evenly; put the mixed raw materials into a vacuum furnace for melting, specifically: mix The final raw material is put into a vacuum furnace and heated to 1100°C, and after 12.5 hours of heat preservation, the slag is removed to remove impurities; after heat preservation, nitrogen gas is introduced and the furnace temperature is lowered to 860°C for 6 hours of refining; when the furnace temperature drops to 720°C, the molten iron is poured into In the mold, the bar is obtained after cooling and demoulding; the bar is drawn in an automatic wire drawing machine to obtain a steel wire with a diameter of 3.5 mm; the steel wire is pressed into a strip steel wire with a thickness of 0.7 mm and a width of 3.2 mm th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com