Unpowered sand suction device and method

A power and gravity technology, applied in the field of unpowered sand suction devices, can solve the problems of the decline of the water storage capacity of the reservoir, the influence of the use capacity of the reservoir, and the reduction of the water storage capacity, so as to reduce the waste of water resources, reduce the sand suction efficiency and save labor and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

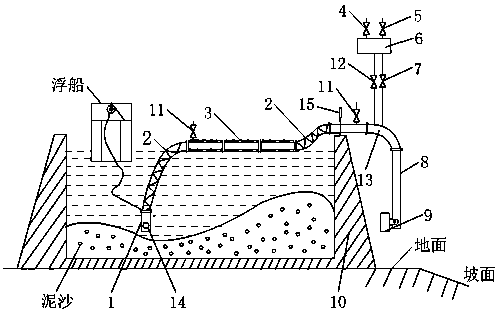

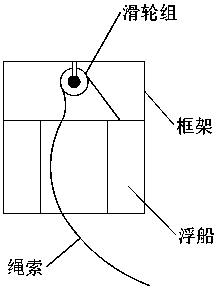

[0022] As shown in the figure, a non-powered sand suction device includes a polyurethane insulation pipe 3 , a water storage tank 6 and a siphon elbow 13 . The polyurethane insulation pipe 3 floats on the water surface, one end is connected with the vertical gravity suction head 1 through the metal hose 2, and the other end is connected with the siphon elbow 13 through the metal hose 2.

[0023] The upper end of the siphon elbow 13 is connected to the water storage tank 6 through a water inlet pipe 12 with a valve and a ventilation pipe 7 with a valve. The other side of the siphon elbow 13 is connected to the power generation pipe 8 through a flange; the bottom end of the power generation pipe 8 is connected to the siphon start valve 9 with a fixed shaft.

[0024] Diving goggles 14 are installed at the bottom of the vertical gravity suction head 1 .

[0025] The polyurethane insulation pipe 3 is provided with a vent valve 11 .

[0026] The siphon elbow 13 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com