Method for producing GlcNAc salts by enzymic method and purifying GlcNAc salts

A technology of glucosamine salt and purification method, which is applied in the field of enzymatic production of glucosamine salt and its purification, can solve problems such as high energy consumption and high pollution, and achieve the effects of low raw material consumption, high conversion rate and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

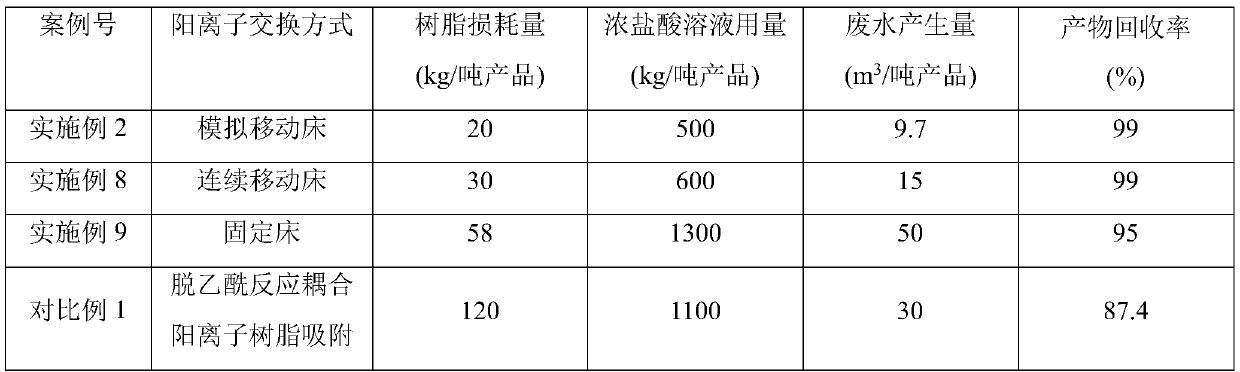

Examples

Embodiment 1

[0059] according to figure 1 The process route shown, the operation steps are as follows:

[0060] (1) Use acetylglucosamine solution with a concentration of 40-150g / L as raw material, add deacetylase solution or deacetylase preparation according to the ratio of 10-30U / g acetylglucosamine, and the pH range of the enzyme reaction is 4.0-8.0 , the reaction temperature is 25-45°C, and the reaction is stirred for 10-40min;

[0061] This step specifically removes the acetyl group in the N-acetylglucosamine molecule, and reacts to obtain an enzyme hydrolyzate whose main components are glucosamine and acetic acid. The pH of the enzyme reaction is preferably 7.0-8.0;

[0062] (2) The enzyme hydrolyzate after the step (1) reaction is transported in the ultrafiltration membrane equipment, the molecular weight cut-off of the ultrafiltration membrane is 5-200kDa, preferably 5-30kDa; Ultrafiltration membrane dialysate and deacetylase-containing membrane concentrate, the recovery rate of ...

Embodiment 2

[0078] according to figure 1 The process route shown, the operation steps are as follows:

[0079] (1) Collect 350m 3 The concentration is 102kg / m 3 The acetylglucosamine solution in the storage tank, pump the acetylglucosamine solution into the enzyme reaction tank, add the deacetylase solution according to the ratio of 10-25U / g acetylglucosamine, the pH of the enzyme reaction is 7.0-8.0, and the reaction temperature at 37°C, stirring for 30 minutes;

[0080] (2) Pump the enzyme hydrolyzate after the reaction in step (1) into the ultrafiltration membrane equipment, the molecular weight cut-off of the ultrafiltration membrane is 5000Da, add 60m 3 Pure water is used for the dialysis membrane concentrate, and the ultrafiltration membrane dialysis fluid and the membrane concentrate are collected separately; a total of 380m 3 The content is 56.3kg / m 3 of glucosamine dialysate; 30m of membrane concentrate 3 The enzyme liquid is returned to the deacetylase liquid storage tank to...

Embodiment 3

[0095] according to figure 1 The process route shown is different in that, on the basis of Example 2, the nanofiltration membrane concentration equipment is replaced with reverse osmosis ceramic membrane equipment, that is, the column liquid under the negative column obtained in step (4) is collected to the reverse osmosis ceramic membrane equipment, the pore size of the reverse osmosis membrane is 1nm, and the operating pressure is 0.5-1.0MPa. The liquid concentrated by the reverse osmosis ceramic membrane equipment is returned to the enzyme reaction tank to participate in the next batch of enzyme reaction process.

[0096] In this production process, the production of 1 ton of glucosamine hydrochloride consumes 11 tons of pure water and produces 10.5 tons of waste water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com