Antistatic agent, antistatic release film and preparation method of antistatic release film

An antistatic agent and antistatic technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of complex manufacturing process, affecting texture, and low production efficiency, and achieve stable chemical and physical properties, stable antistatic ability, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

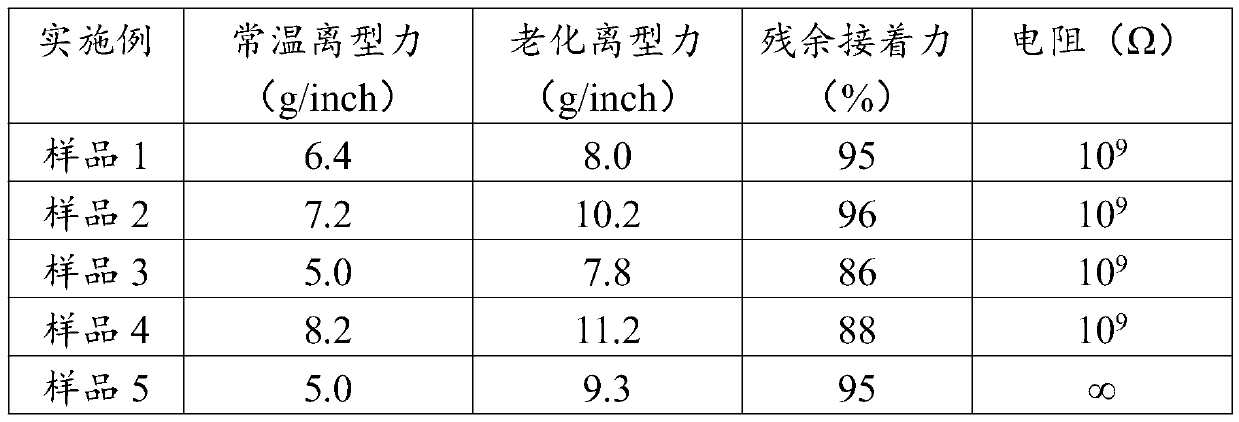

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing an antistatic release film, comprising the steps of:

[0038] Mixing the conductive monomer, photocurable organosiloxane resin, photocurable silicone release agent and photoinitiator according to the weight ratio to obtain a mixture, and placing the mixture on the surface of the base film layer;

[0039] The set base film layer is subjected to photocuring treatment to obtain an antistatic release film.

[0040] In the present invention, the thickness of the mixture disposed on the surface of the base film layer is preferably 0.4-0.6 μm, more preferably 0.45-0.5 μm.

[0041] In the present invention, the photocuring treatment is preferably ultraviolet curing, and the irradiation intensity of the ultraviolet light is preferably 80-120W / cm, more preferably 90-110W / cm; the irradiation dose is preferably 100-400J / cm 2 , more preferably 200-300J / cm 2 ; The irradiation time is preferably 3-20s, more preferably 8-15s....

Embodiment 1

[0045] Take 100 grams of vinylmethyl oxazolidinone, 100 grams of photocurable organosiloxane resin TEGO RC711, 800 grams of photocurable silicone release agent TEGO RC902, 20 grams of photoinitiator TEGO PHOTOINITIATOR A18; put the above raw materials in order Mix and stir for 30 minutes to prepare the mixture; place the mixture on the surface of the PET film with a coating thickness of 0.5 μm; then perform UV curing, the irradiation intensity of ultraviolet light is 120W / cm, and the irradiation dose is 300J / cm 2 , The irradiation time was 3s, and the antistatic release film sample 1 was obtained.

Embodiment 2

[0047]Take 100 grams of vinylmethyl oxazolidinone, 100 grams of photocurable organosiloxane resin TEGO RC722, 800 grams of photocurable silicone release agent TEGO RC902, 20 grams of photoinitiator TEGO PHOTOINITIATOR A18; put the above raw materials in order Mix and stir for 30 minutes to prepare the mixture; place the mixture on the surface of the PET film with a coating thickness of 0.5 μm; then perform UV curing, the irradiation intensity of UV light is 120W / cm, and the irradiation dose is 300J / cm 2 , The irradiation time was 3s, and the antistatic release film sample 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com