Preparation method of printing paste for reactive dye direct printing

A printing paste and reactive dye technology, applied in the field of chemical printing and dyeing, can solve the problems of poor thickening effect and water retention, printing color paste failure, short color paste stability period, etc., to achieve obvious thickening effect, soft hand feeling, Good printing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Take 1wt% sulfuric acid (catalyst) and add it to 55wt% glycolic acid and keep stirring at 60°C to fully dissolve the sulfuric acid.

[0020] 2) Add 100g of 15wt% alginic acid slurry to the above 7.8g solution while stirring, adjust the pH to 3.5, mix evenly, and stir and reflux for 24 hours at a reaction temperature of 120°C-135°C.

[0021] 3) Wash the product after the reaction in 2) with absolute ethanol for 3-4 times, recover the washing solution, dry the cleaned product at a temperature of 85°C-100°C, remove excess ethanol, and obtain alginate glycolate powder .

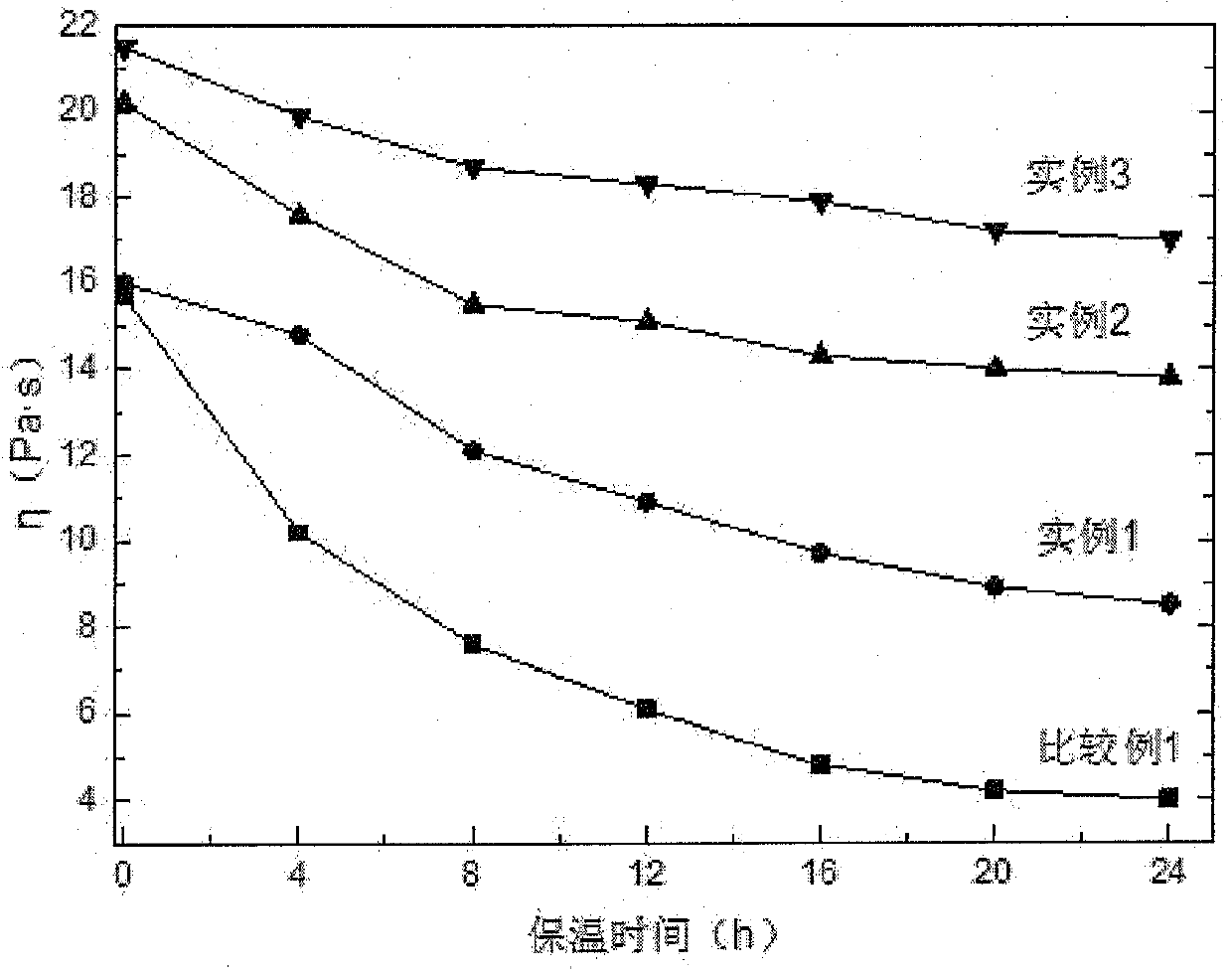

[0022] Take 3) the obtained powder and make it into a paste with a mass fraction of 2%, and use a viscometer to measure the viscosity. The higher the viscosity, the better the paste. The paste was kept at a constant temperature of 60°C for 24 hours, and the viscosity was measured every 4 hours. Track the viscosity change of the paste, the smaller the viscosity change, the better the paste stability. ...

Embodiment 2

[0024] 1) Take 1wt% sulfuric acid (catalyst) and add it to 15wt% oxalic acid solution, stir for 15 minutes to fully mix sulfuric acid and oxalic acid.

[0025] 2) Add 100g of 15wt% alginic acid slurry to the above 33.89g solution while stirring, adjust the pH to 3 after mixing evenly, and stir and reflux for 24 hours at a reaction temperature of 120°C-135°C.

[0026] 3) Wash the product after the reaction in 2) with absolute ethanol for 3-4 times, recover the washing solution, dry the cleaned product at a temperature of 85°C-100°C, remove excess ethanol, and obtain alginate oxalate powder.

[0027] Take 3) the obtained powder and make it into a paste with a mass fraction of 2%, and use a viscometer to measure the viscosity. The higher the viscosity, the better the paste. The paste was kept at a constant temperature of 60°C for 24 hours, and the viscosity was measured every 4 hours. Track the viscosity change of the paste, the smaller the viscosity change, the better the past...

Embodiment 3

[0029] 1) Take 1wt% sulfuric acid (catalyst) and add it to 55% propionic acid, stir in a cold water bath for 15 minutes, so that the sulfuric acid and propionic acid are fully mixed.

[0030] 2) Add 100g of 15wt% alginic acid slurry to the above 9.24g solution while stirring, adjust the pH to 2 after mixing evenly, and stir and reflux for 24 hours at a reaction temperature of 100°C-135°C.

[0031] 3) Wash the product after the reaction in 2) with absolute ethanol for 3-4 times, recover the washing solution, dry the cleaned product at a temperature of 85°C-100°C, remove excess ethanol, and obtain alginate propylate solid.

[0032] Take 3) the obtained powder and make it into a paste with a mass fraction of 2%, and use a viscometer to measure the viscosity. The higher the viscosity, the better the paste. The paste was kept at a constant temperature of 60°C for 24 hours, and the viscosity was measured every 4 hours. Track the viscosity change of the paste, the smaller the visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com