A kind of printing ink composition and its application in cotton cloth printing

An ink composition and printing technology, applied in the directions of ink, application, household appliances, etc., can solve the problems such as failure to realize the commercialization of reactive dye cotton cloth printing, low color fixation rate of direct printing and dyeing, light color of printing pattern, etc. The effect of fixing color, dark printing pattern and high depaste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

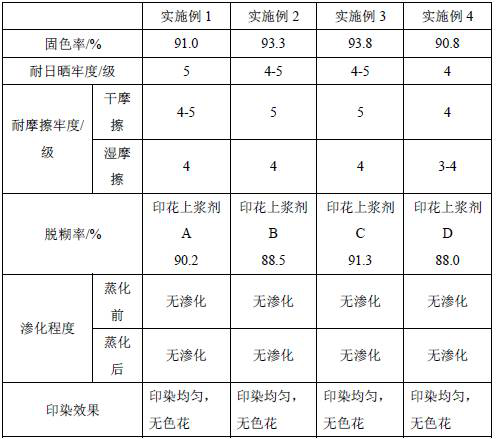

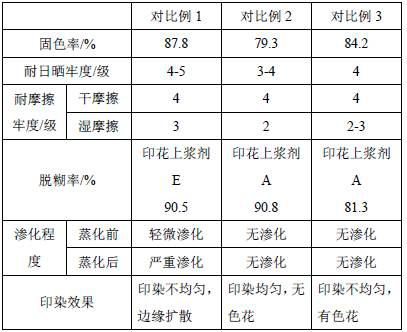

Examples

Embodiment 1~4

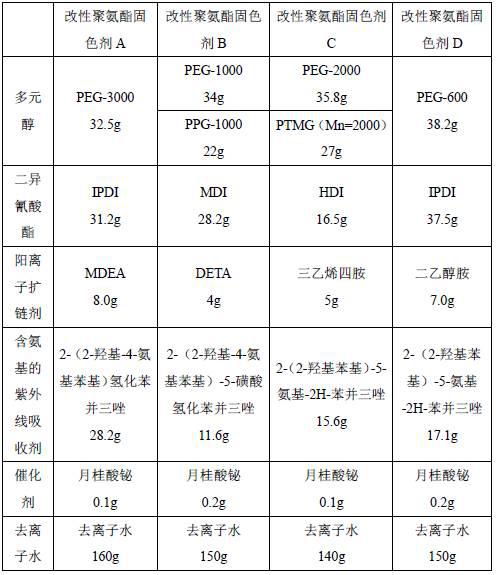

[0046] The main components of the modified polyurethane color fixing agents A to D are shown in Table 1.

[0047] The composition of table 1 modified polyurethane color fixing agent

[0048]

[0049] The concrete preparation process of modified polyurethane color fixing agent A is as follows:

[0050] S1. The dehydrated polyethylene glycol and isophorone diisocyanate were reacted together under the action of bismuth laurate for 2 hours, and then N-methyldiethanolamine was added for chain extension reaction for 2 hours to generate a terminal group of -NCO Polyurethane; the reaction temperature is 90°C;

[0051] S2. After the reactant is cooled to 50°C, add 2-(2-hydroxy-4-aminophenyl)hydrobenzotriazole for capping, and react for 1 hour; use acetone to reduce the viscosity during the polymerization process;

[0052] S3. Add deionized water and emulsify for 40 minutes at a stirring speed of 800r / min; remove acetone by vacuuming to obtain modified polyurethane color fixing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com