Raw material batch for producing magma rock fibers and preparation method of magma rock fibers

The technology of magmatic rock and batching material is applied in the field of inorganic non-metallic material magmatic rock fiber and its preparation, and can solve the problem of the design of chemical composition and main mineral composition of difficult magmatic rock fiber material, poor heat permeability of pure natural basalt melt, It is difficult to scale and stabilize industrial production, etc., to achieve the effect of improving wire drawing performance, facilitating large-scale and stable industrial production, and being suitable for wire drawing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

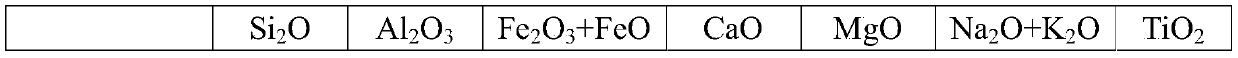

[0040] The raw material batching material used for producing magmatic rock fiber and the preparation method of magmatic rock fiber, according to weight percentage, 90% of magmatic rock 3 and 10% of diopside are evenly mixed, and after grinding, they are passed through an 80-mesh sieve to produce It is used as a batch material for the production of magma rock fiber; the main chemical composition and weight percentage of the batch material are: SiO 2 53.89%, A1 2 o 3 13.44%, Fe 2 o 3 +FeO 9.54%, CaO 9.99%, MgO 6.11%, Na 2 O+K 2 O 4.10%, TiO 2 1.47%, the remaining 1.46% (mainly a small amount of Mn, P, S, Ba, Sr, Zr, Cu, Zn, Nb, Rb, Y, Pr, La, Ni, Lu, Mo, Nd, Sc, Ta, Tb , W, Th, U, Tm, etc., ten or more compounds); the batch material was melted at 1450°C for 16 hours, and then drawn with a single-hole platinum wire drawing furnace at 1270°C to obtain a magma rock fiber with a diameter of 10 μm ; The tensile strength of new ecological original silk of magmatic rock fiber...

Embodiment 2

[0042] The raw material batching material for producing magmatic rock fiber and the preparation method of magmatic rock fiber, according to weight percentage, 40% magmatic rock 4, 50% diopside, 5% spodumene, 5% alumina are mixed evenly, Pass through 80-mesh sieve after grinding to make a batch material for producing magmatic rock fiber; the main chemical composition and weight percentage of the batch material are: SiO 2 52.44%, A1 2 o 3 12.29%, Fe 2 o 3 +FeO 5.87%, CaO 14.89%, MgO 9.14%, Na 2 O+K 2 O 1.77%, TiO 2 1.38%, Li 2 O 0.25%, the rest 1.97% (mainly a small amount of Mn, P, S, Ba, Sr, Zr, Cu, Zn, Nb, Rb, Y, Pr, La, Ni, Lu, Mo, Nd, Sc, Ta, Ten or more compounds of Tb, W, Th, U, Tm, etc.); the batch material was melted at 1430°C for 18 hours, and then drawn with a single-hole platinum wire drawing furnace at 1250°C to obtain a magma rock with a diameter of 10 μm fiber; the tensile strength of the new ecological original silk of magma rock fiber is 3508MPa.

Embodiment 3

[0044] The raw material batching material used to produce magmatic rock fiber and the preparation method of magmatic rock fiber, according to the weight percentage, 50% magmatic rock 5, 40% diopside, 10% pyrophyllite are mixed evenly, and after grinding, pass through an 80-mesh sieve, It is made into a batch for producing magma rock fiber; the main chemical composition and weight percentage of the batch are: SiO 2 51.94%, A1 2 o 3 11.40%, Fe 2 o 3 +FeO 7.64%, CaO 14.21%, MgO 8.56%, Na 2 O+K 2 O 2.13%, TiO 2 1.27%, the remaining 2.85% (mainly a small amount of Mn, P, S, Ba, Sr, Zr, Cu, Zn, Nb, Rb, Y, Pr, La, Ni, Lu, Mo, Nd, Sc, Ta, Tb Ten or more compounds among , W, Th, U, Tm, etc.); the batch material was melted at 1430°C for 18 hours, and drawn at 1240°C with a single-hole platinum drawing furnace to obtain magma rock fibers with a diameter of 10 μm ; The tensile strength of new ecological original silk of magmatic rock fiber is 3315MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com