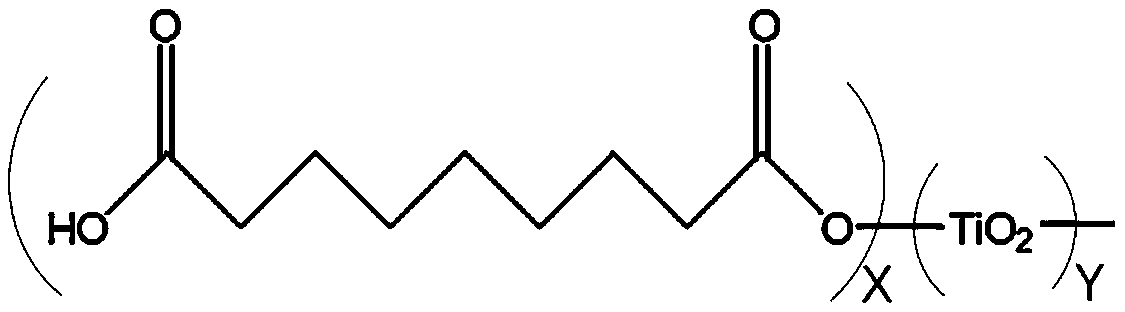

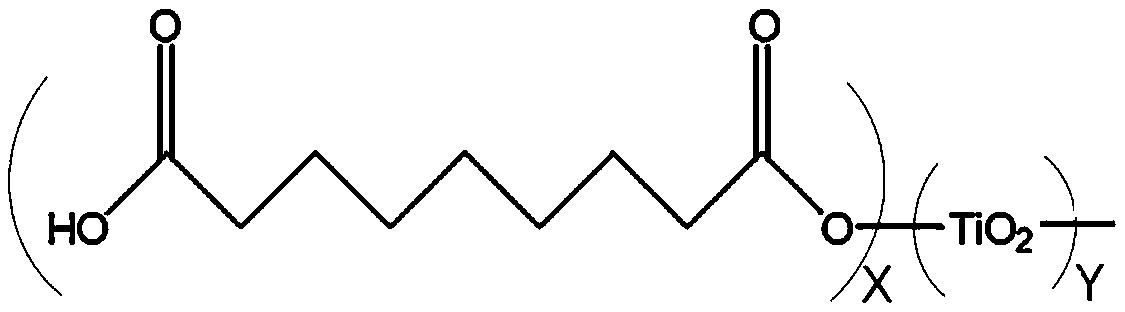

Azelaic acid/titanium dioxide hybrid composite material and preparation method thereof

A kind of azelaic acid, composite material technology, applied in cosmetic preparations, titanium organic compounds, cosmetics and other directions, to achieve the effect of improving sunscreen ability, enhancing structural stability, and ensuring orderly dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of rhododendronic acid / titanium dioxide hybrid composite material, comprising the following steps:

[0025] Step 1. Add 350mL of rutile nano-titanium dioxide aqueous solution with a mass concentration of 0.8% in the reaction vessel, stir until uniformly dispersed, then add 2.8mL of 50wt% sodium hydroxide aqueous solution dropwise, and heat up at a rate of 25°C / h after the addition is completed to 70°C, react for 12 hours; after the reaction is completed, cool down to below 60°C, wash and filter with 3 times of water, and obtain intermediate product of hydroxylated titanium dioxide;

[0026] Step 2. Under continuous stirring, dissolve the above hydroxylated titanium dioxide intermediate in 600g of isopropanol solution, stir for 30min at 80°C and 1000r / min, add 79mL of 10wt% rhododendronic acid isopropanol solution, and mix 30min; add 0.02wt% sulfuric acid accounting for the total mass of azalea in the rhododendron isopropanol solution, and react unde...

Embodiment 2

[0028] A preparation method of rhododendronic acid / titanium dioxide hybrid composite material, comprising the following steps:

[0029] Step 1. Add 350mL of rutile nano-titanium dioxide aqueous solution with a mass concentration of 0.5% into the reaction vessel, stir until uniformly dispersed, then add 4.36mL of 40wt% sodium hydroxide aqueous solution dropwise, and heat up at a rate of 30°C / h after the addition is completed to 80°C, react for 12 hours; after the reaction is completed, cool down to below 60°C, wash and filter with 3 times of water, and obtain the intermediate product of hydroxylated titanium dioxide;

[0030] Step 2. Under continuous stirring, dissolve the above-mentioned hydroxylated titanium dioxide intermediate in 600 g of isopropanol solution, stir for 30 min at 80 ° C and 1000 r / min, add 98.5 mL of 10 wt % rhododendron acid isopropanol solution, Mix for 30 minutes; add sulfuric acid accounting for 0.01wt% of the total mass of azelaic acid in the rhododendr...

Embodiment 3

[0032] A preparation method of rhododendronic acid / titanium dioxide hybrid composite material, comprising the following steps:

[0033] Step 1. Add 150mL of rutile nano-titanium dioxide aqueous solution with a mass concentration of 2% in the reaction vessel, stir until uniformly dispersed, then add 5.0mL of 60wt% sodium hydroxide aqueous solution dropwise, and heat up at a rate of 30°C / h after the addition is completed to 85°C, react for 12 hours; after the reaction is completed, cool down to below 60°C, wash and filter with 3 times of water, and obtain intermediate product of hydroxylated titanium dioxide;

[0034] Step 2. Under continuous stirring, dissolve the above hydroxylated titanium dioxide intermediate in 600g of isopropanol solution, stir for 30min at 80°C and 1000r / min, add 141mL of 10wt% rhododendronic acid isopropanol solution, and mix 30min; add 0.01wt% sulfuric acid accounting for the total mass of azalea in the rhododendron isopropanol solution, and react under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com