Method for preparing proanthocyanidin whitening sunscreen cream

A technology of proanthocyanidins and oligomeric proanthocyanidins, which is applied in the field of skin care products, can solve the problems of insufficient utilization of oligomeric proanthocyanidins, unreasonable preparation methods and formulations, and difficulty in achieving whitening and sunscreen effects, thereby improving whitening and sun protection. Sunscreen effect, preparation method and formulation optimization, effect applicable to a wide range of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

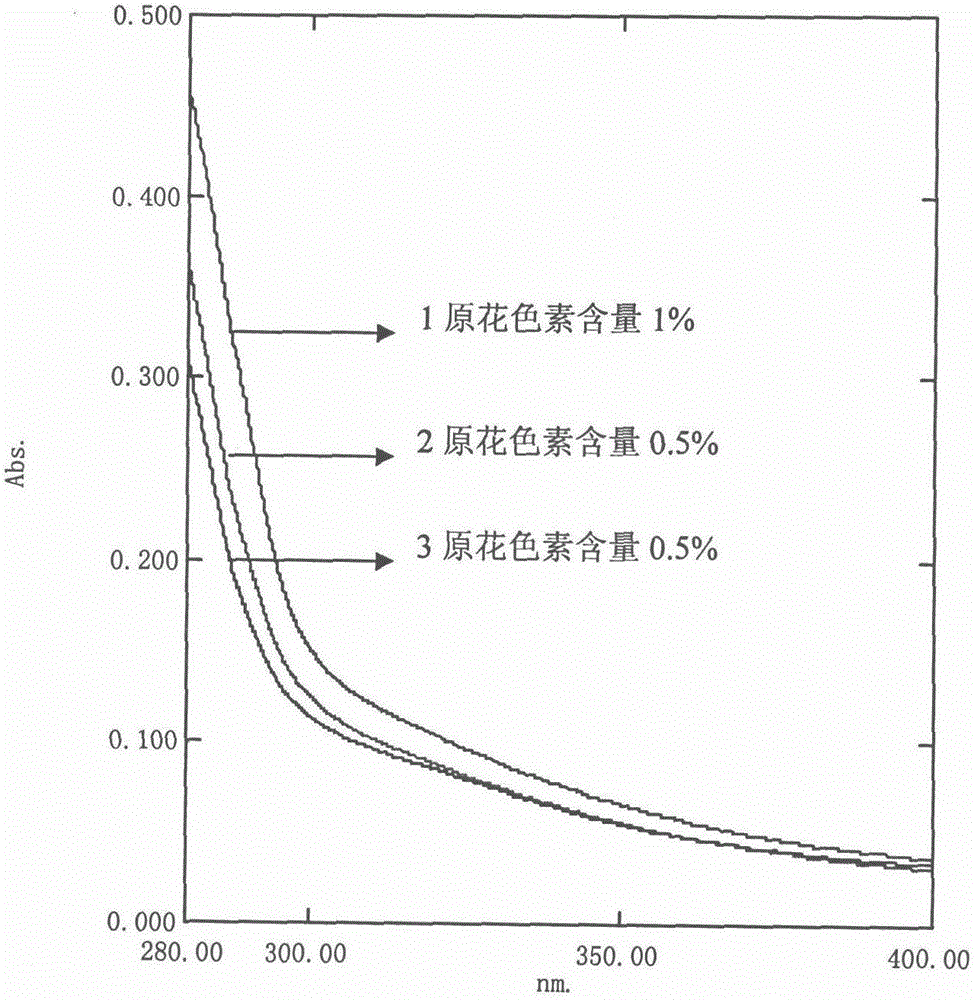

[0029] The oil phase and the water phase in the formula are prepared respectively, wherein the proanthocyanidin is 1g, and the content is 1%. Heat and stir separately to keep warm to 80°C, slowly add the water phase into the oil phase, and stir while heating. After complete addition, adjust the temperature to 85°C, stir at 500r / min, and keep it for 30 minutes. After the end, slowly lower the temperature to 80°C, add azone, and vacuum the pressure to -0.04mPa for 20 minutes. When the temperature drops to about 45°C, add a small amount of flavor and fragrance, continue to stir for 10 minutes and discharge. The obtained product has good stability and uniform texture.

Embodiment 2

[0031] The oil phase and the water phase in the formula are prepared respectively, wherein the amount of proanthocyanidin is 2g, and the content is 2%. Heat and stir separately to keep warm to 80°C, slowly add the water phase into the oil phase, and stir while heating. After complete addition, adjust the temperature to 85°C, stir at 500r / min, keep for 20min, then slowly cool down to 80°C, add azone, and vacuum the pressure to -0.05mPa for 20min. When the temperature drops to about 45°C, add a small amount of flavor and fragrance, continue to stir for 10 minutes and discharge. The obtained product has good stability and uniform texture.

Embodiment 3

[0033] The oil phase and the water phase in the formula are prepared respectively, wherein the amount of proanthocyanidin is 3g, and the content is 3%. Heat and stir separately to keep warm to 75°C, slowly add the water phase into the oil phase, and stir while heating. After complete addition, adjust the temperature to 80°C, stir at 500r / min, keep for 20min, then slowly cool down to 80°C, add azone, and vacuum the pressure to -0.05mPa for 30min. When the temperature drops to about 45°C, add a small amount of flavor and fragrance, continue to stir for 10 minutes and discharge. The obtained product has good stability, uniform texture, but darker color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com