Polyurethane foams for comfort applications

A polyurethane and foam technology, applied in the field of flexible polyurethane foam, can solve the problems of low compression set, heat dissipation, low foam density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-2

[0095] Examples 1-2 and Comparative Samples A-F

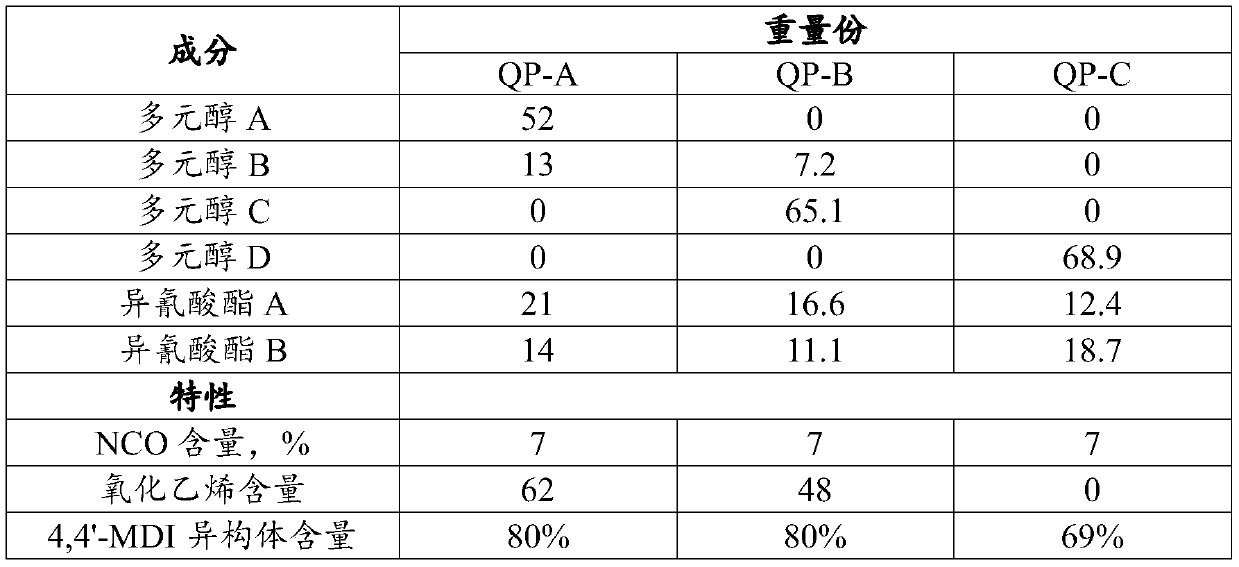

[0096] A. Quasi-prepolymer formation

[0097] Quasi-prepolymers A-C were prepared from the ingredients as indicated in Table 1 in the following general manner. One or more polyols were dried to a moisture content of less than 250 ppm by heating the polyol to 100° C. overnight with stirring under nitrogen. A trace amount of benzoyl chloride was added to the dry polyol and stirred. Separately, one or more polyisocyanates are heated to 50°C and combined with one or more polyols. No urethane catalyst is added to the resulting reaction mixture, which contains not more than 1 part per million by weight of metal and not more than 100 parts per million of amine compound. The reaction mixture was heated at 75°C under nitrogen until a constant isocyanate content was obtained. The quasi-prepolymer was then cooled to room temperature and stored under nitrogen.

[0098] NCO content was measured according to ASTM D5155. The ethylene o...

example 2

[0122] Example 2 is the same as Comparative Sample B and Comparative Sample C except that both the silicone surfactant and the ethylene oxide / propylene oxide block copolymer are present in the aqueous phase. Density reduced to less than 60kg / m 3 , and the compression set was significantly reduced to 10%. At the same time, good moisture absorption is retained and a high air flow rate is obtained.

example 1

[0123] Example 1 shows the effect of using a quasi-prepolymer with a slightly lower ethylene oxide content. The density is significantly lower than any of Comparative Samples A-C, and the compression set is significantly lower. Moisture is retained. Example 1 represents a significant improvement over Comparative Samples A-C.

[0124] Comparative Sample D and Comparative Sample E demonstrate the effect of varying the amount of polymer polyol. Too little polymer polyol (D) or too much polymer polyol (E) can result in a significant and undesirable increase in compression set. Too little polymer polyol also results in a significant increase in density.

[0125] Comparative Sample F demonstrates the need for the quasi-prepolymer to contain oxyethylene groups. Quasi-prepolymers are not even capable of forming stable foams without the hydrophilic properties imparted by the oxyethylene groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com