Degradable magnesium alloy laminating bone nail and preparation method

A magnesium alloy and bone nail technology, applied in the field of magnesium alloy, can solve the problems of poor plastic deformation ability and insufficient mechanical properties, and achieve strong mechanical properties, good biocompatibility, and reduce the concurrent effects of inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

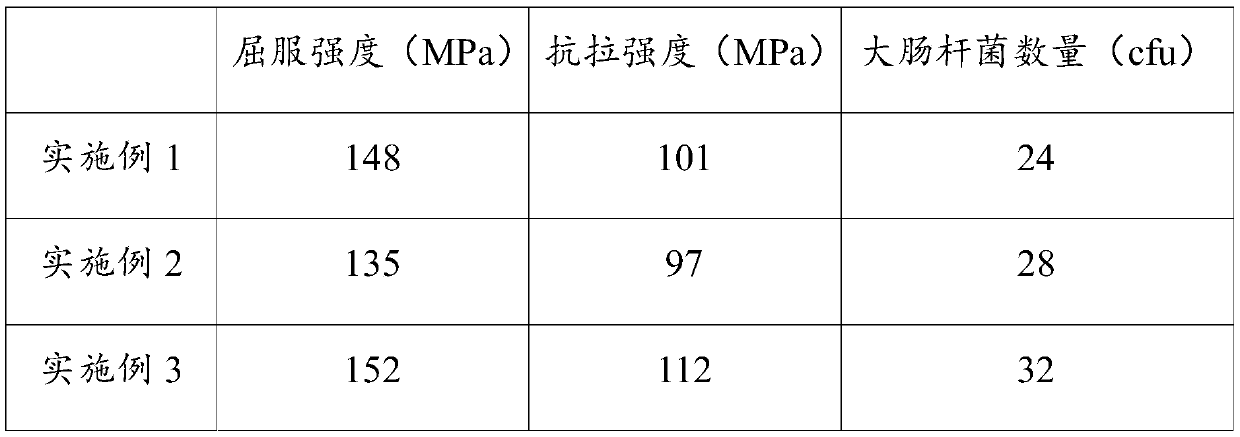

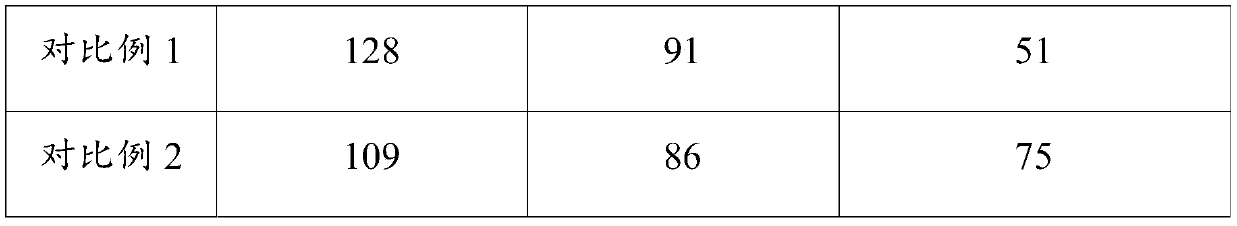

Examples

preparation example Construction

[0027] The preparation method of the degradable magnesium alloy covered bone nail of the present invention comprises the following steps in sequence:

[0028] (1) Pretreat the body of the magnesium alloy bone nail to remove surface impurities;

[0029] (2) Magnetron sputtering coating is carried out on the surface of the magnesium alloy bone nail body with a silver-copper target;

[0030] (3) Clean the body of the magnesium alloy bone nail.

[0031] Wherein, the pretreatment in step (1) may be pickling, sandblasting, or polishing, and the specific pretreatment process steps may be conventional operations, as long as the impurities on the surface of the magnesium alloy bone nail body can be removed.

[0032] In step (2), the preparation method of silver-copper target material comprises the following steps:

[0033] a. Melting copper and silver under a protective atmosphere to obtain a liquid alloy;

[0034] b. Spraying and depositing the liquid alloy to obtain a silver-coppe...

Embodiment 1

[0040] A degradable magnesium alloy covered bone nail, comprising a magnesium calcium alloy bone nail body and AgCu deposited on the magnesium calcium alloy bone nail body 3 layer, AgCu 3 The thickness of the layer is 1 μm.

[0041] Its preparation method comprises the following steps successively:

[0042] (1) Pre-polishing the body of the magnesium-calcium alloy bone nail to remove surface impurities;

[0043] (2) Magnetron sputtering coating is carried out on the surface of the magnesium-calcium alloy bone nail body using silver-copper targets;

[0044] (3) Clean the main body of the magnesium-calcium alloy bone nail with pure water.

[0045] Wherein, the preparation method of silver-copper target material comprises the following steps:

[0046] a. Melting copper and silver under a protective atmosphere to obtain a liquid alloy;

[0047] b. Spraying and cooling the liquid alloy in sequence to obtain silver-copper alloy ingots;

[0048] c. performing homogenization ann...

Embodiment 2

[0052] A degradable magnesium alloy covered bone nail, comprising a magnesium calcium alloy bone nail body and AgCu deposited on the magnesium calcium alloy bone nail body 3 layer, AgCu 3 The thickness of the layer is 0.5 μm.

[0053] Its preparation method comprises the following steps successively:

[0054] (1) Pre-polishing the body of the magnesium-calcium alloy bone nail to remove surface impurities;

[0055] (2) Magnetron sputtering coating is carried out on the surface of the magnesium-calcium alloy bone nail body using silver-copper targets;

[0056] (3) Clean the main body of the magnesium-calcium alloy bone nail with pure water.

[0057] Wherein, the preparation method of silver-copper target material comprises the following steps:

[0058] a. Melting copper and silver under a protective atmosphere to obtain a liquid alloy;

[0059] b. Spraying and cooling the liquid alloy in sequence to obtain silver-copper alloy ingots;

[0060] c. performing homogenization a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com