Prefabricated modular composite floor

A combined floor, modular technology, applied in the direction of floor, building components, construction, etc., can solve the problems of increased labor, high consumption, long movement of workers, etc., to achieve convenient management and production, saving plant area, and easy quality. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

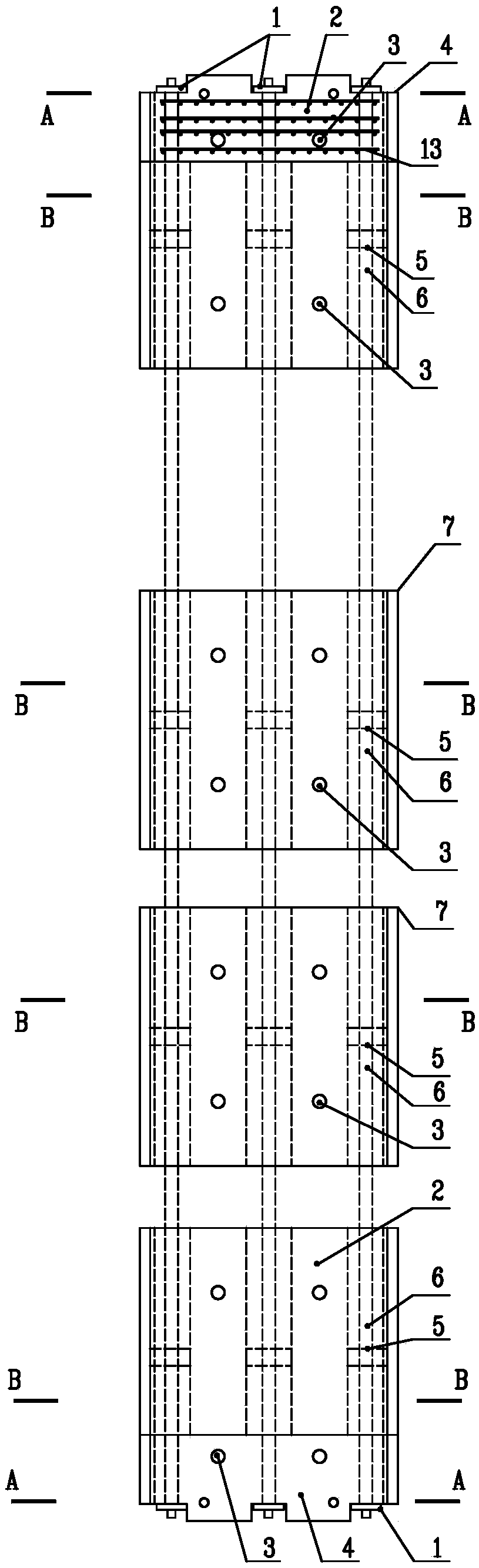

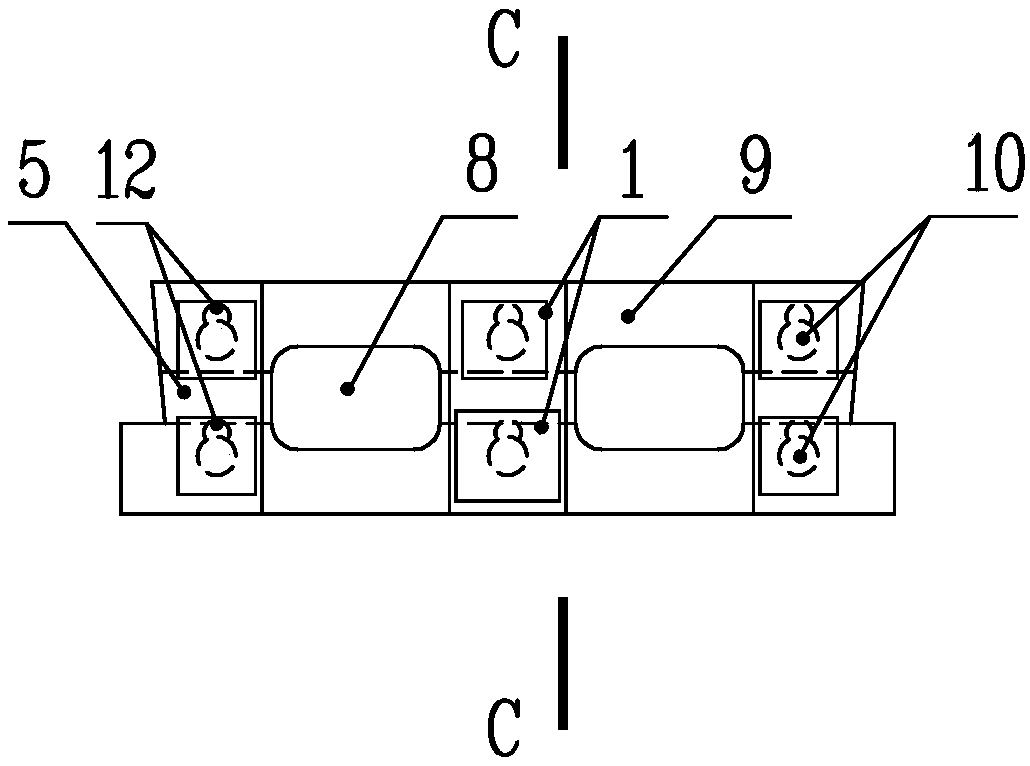

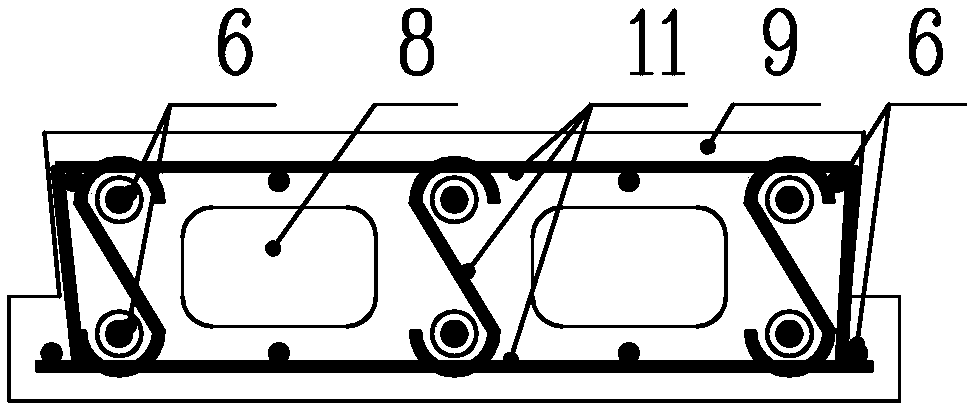

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as Figure 1~4 As shown in , the prefabricated modular composite floor slab is combined into a prefabricated floor slab by independently prefabricated end modules 4 and intermediate modules 7 through prestressed steel bars 6, including a plurality of intermediate modules 7 and an end module assembled at both ends of the prefabricated floor slab. Module 4, the outline size of the joint surface of the end module 4 and the middle module 7 is the same, for the floor slabs of the same width, the end module 4 can be prefabricated into a unified structure, and the middle module 7 can be set to have the same modulus as required Based on several different lengths, cooperate with each other into the required length to reduce the number of intermediate modules. Through such cooperation, the production of prefabricated floor slabs of different lengths only requires the combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com