Immobilized fermentation method for controlling higher alcohol content of yellow rice wine

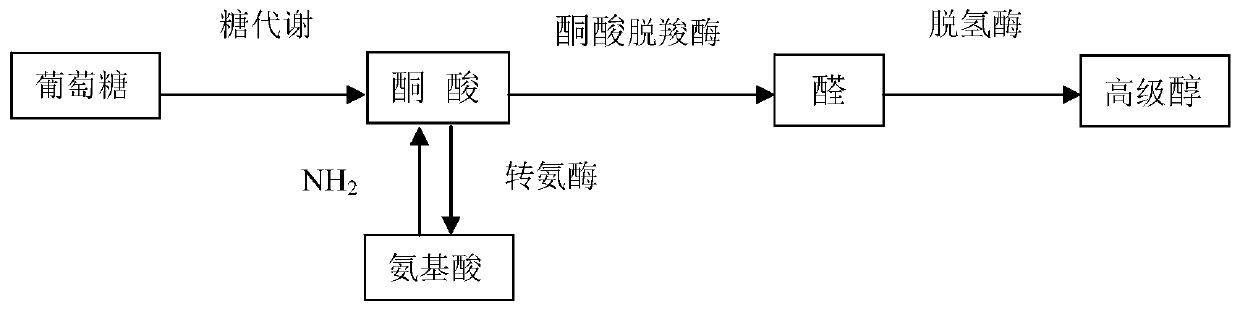

A technology of immobilized fermentation and immobilized yeast, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve problems such as large fluctuations in higher alcohol content, and achieve control content, simplified links, and the effect of improving the ability of other miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

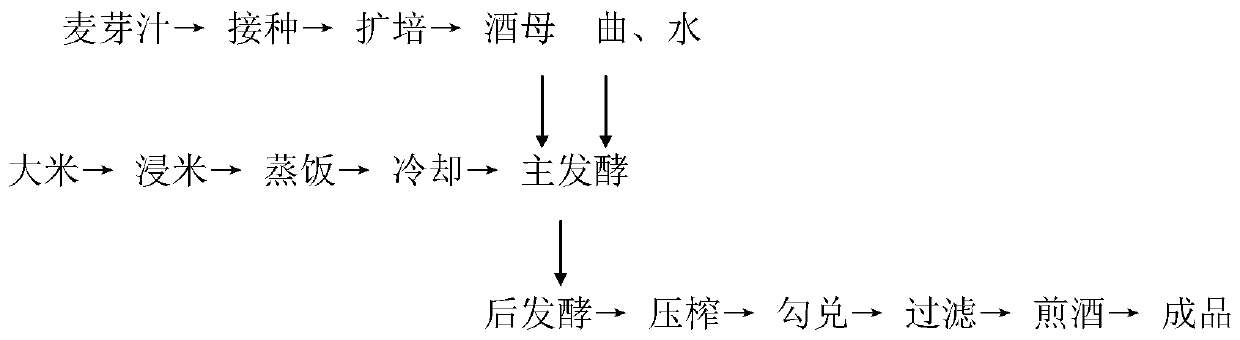

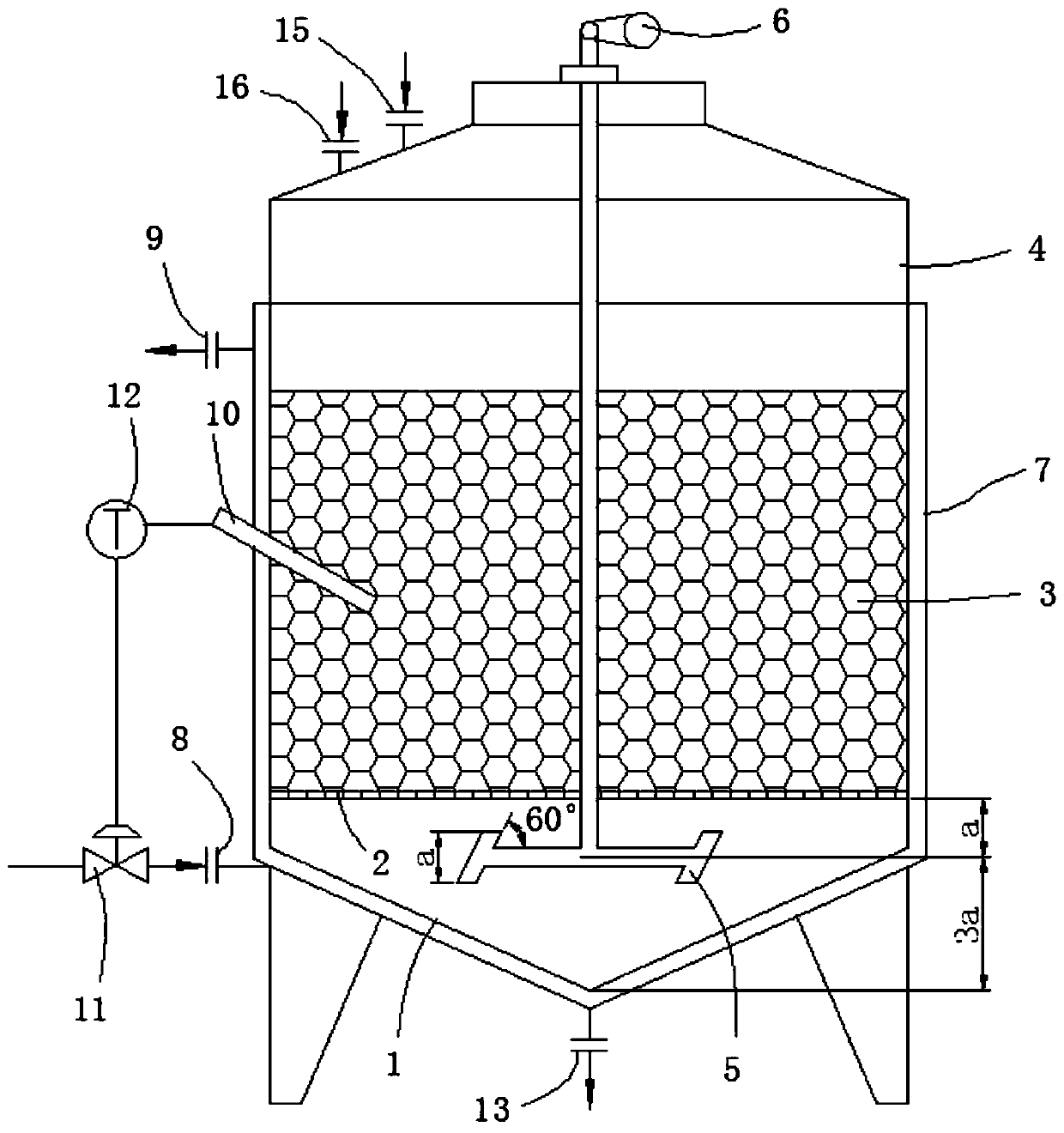

Method used

Image

Examples

Embodiment 1

[0040] An immobilized fermentation method for controlling the higher alcohol content of yellow rice wine, comprising the steps of:

[0041] Step 1: Whitening of rice and preparation of rice flour slurry

[0042] A. rice whitening 4400kg, whitening rate=89.5%, described whitening rate=white rice / brown rice×100%;

[0043]B. Grind into powder, pass through a 60-mesh sieve for later use, add water at a ratio of 1:2.5 to adjust the slurry, stir evenly and add α-amylase and CaCl at a ratio of 30U / g polished white rice 2 Dosage: 2.5g / kg polished white rice, liquefied at 90°C for 60min;

[0044] Step 2: Yeast and its immobilization

[0045] C. Use rice wine yeast, culture in wort of 12°Bx at 26-28°C for 24h, make the cells reach the logarithmic growth phase, and the yeast concentration reach 3.5×10 8 a / mL;

[0046] D. Mix the yeast collected after the centrifugation of the rice wine yeast cultured to the logarithmic phase with 9 times the weight of 2.0% sodium alginate solution, a...

Embodiment 2

[0057] An immobilized fermentation method for controlling the higher alcohol content of yellow rice wine, comprising the steps of:

[0058] Step 1: Whitening of rice and preparation of rice flour slurry

[0059] A. White rice 2200kg, the whitening rate is 89.0%;

[0060] B. Grind into powder, pass through a 60-mesh sieve for later use, add water at a ratio of 1:2.5 to adjust the slurry, stir evenly and add α-amylase and CaCl at a ratio of 30U / g polished white rice 2 Dosage: 2.5g / kg polished white rice, liquefied at 90°C for 60min;

[0061] Step 2: Yeast and its immobilization

[0062] C. Use yellow rice wine yeast, culture in wort of 12°Bx at 26~28°C for 24h, make the cells reach the logarithmic growth phase, and the yeast concentration reach 3.2×10 8 a / mL;

[0063] D. Mix the yeast collected after the centrifugation of rice wine yeast cultured to the logarithmic phase with 1.9% sodium alginate solution 9 times its weight, and add it dropwise to 4% CaCl with a 20L porous s...

Embodiment 3

[0074] An immobilized fermentation method for controlling the higher alcohol content of yellow rice wine, comprising the steps of:

[0075] Step 1: Whitening of rice and preparation of rice flour slurry

[0076] A. White rice 1100kg, white rate = 88.5%;

[0077] B. Grind into powder, pass through a 60-mesh sieve for later use, add water at a ratio of 1:2.5 to adjust the slurry, stir evenly and add α-amylase and CaCl at a ratio of 30U / g polished white rice 2 Dosage: 2.5g / kg polished white rice, liquefied at 90°C for 60min;

[0078] Step 2: Yeast and its immobilization

[0079] C. Use yellow rice wine yeast, culture it in 12°Bx wort at 26~28°C for 20h, make the cells reach the logarithmic growth phase, and the yeast concentration reach 2.8×10 8 a / mL;

[0080] D. Mix the yeast collected after the centrifugation of the rice wine yeast cultured to the logarithmic phase with 9 times the weight of 1.8% sodium alginate solution, and add it dropwise to 4% CaCl with a 20L porous syr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com