Universal liquid perfusion lubricating coating and preparation method thereof

A liquid perfusion and lubricating coating technology, applied in the field of bionic material chemistry, can solve the problems of poor pressure stability, no liquid perfusion lubricating coating, easy adsorption of bacteria and proteins, etc., to achieve good universality and excellent anti-pollution characteristics , Excellent anti-bioadhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

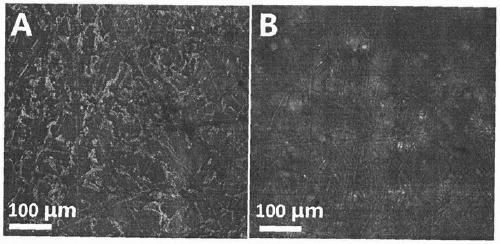

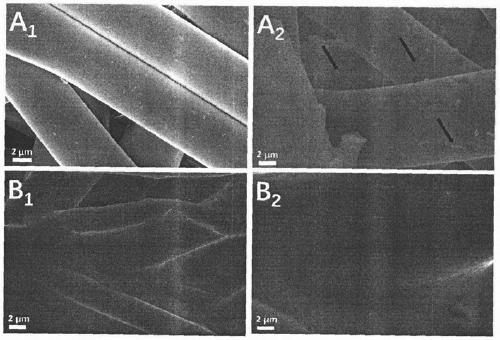

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of universal liquid perfusion lubricating coating and its preparation method, the specific steps are:

[0025] (1) Cleaning the solid substrate: take the polyester non-woven fabric as the solid substrate, ultrasonically clean it with absolute ethanol for 30 minutes, and dry it for later use.

[0026] (2) Polydopamine activation layer: 0.4 g of polyethyleneimine and 0.4 g of dopamine were respectively dissolved in 200 mL of Tris buffer solution (pH=8.5), and mixed thoroughly to prepare a dopamine / polyethyleneimine deposition solution. Then, (1) immerse the cleaned polyester non-woven fabric in the deposition solution, and react with air for 4 hours. Finally, take out the sample and wash it with pure water to remove the residual deposition solution on the surface, and put it in a vacuum drying oven to dry at 60°. A polydopamine activation layer was obtained on the surface.

[0027] (3) Silica nanoparticle layer: Add 1.5mL tetramethyl silicate to 100m...

Embodiment 2

[0032] Embodiment 2: A kind of universal liquid perfusion lubricating coating and preparation method thereof, the specific steps are:

[0033] (1) Cleaning the solid substrate: take the plastic sheet of a disposable lunch box as the solid substrate, ultrasonically clean it with absolute ethanol for 30 minutes, and dry it for later use.

[0034] (2) Polydopamine activation layer: 0.2 g of polyethyleneimine and 0.2 g of dopamine were respectively dissolved in 100 mL of Tris buffer (pH=8.5), and mixed thoroughly to prepare a dopamine / polyethyleneimine deposition solution. Then, (1) immerse the cleaned plastic sheet in the deposition solution, and react with air for 5 hours, finally take out the sample and wash it with pure water to remove the residual deposition solution on the surface, put it into a vacuum drying oven for drying at 60°, and obtain a polymer on the surface of the substrate. Dopamine activation layer.

[0035] (3) Silica nanoparticle layer: Add 3 mL of tetramethy...

Embodiment 3

[0040] Embodiment 3: A kind of universal liquid perfusion lubricating coating and its preparation method, the specific steps are:

[0041] (1) Cleaning the solid substrate: take a glass slide as the solid substrate, ultrasonically clean it with absolute ethanol for 30 minutes, and dry it for later use.

[0042] (2) Polydopamine activation layer: 0.3 g polyethyleneimine and 0.3 g dopamine were respectively dissolved in 150 mL Tris buffer solution (pH=8.5), and mixed well to prepare a dopamine / polyethyleneimine deposition solution. Then, (1) immerse the cleaned glass sheet in the deposition solution, and react with air for 4 hours. Finally, take out the sample and wash it with pure water to remove the residual deposition solution on the surface, and put it into a vacuum drying oven for drying at 60° to obtain a polymer on the surface of the substrate. Dopamine activation layer.

[0043] (3) Silica nanoparticle layer: Add 1.5mL tetramethyl silicate to 100mL hydrochloric acid (1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com