Preparation method of fluorine-containing polymer/polyimide composite film

A polyimide and composite film technology is applied in the field of preparation of fluorine-containing polymer/polyimide composite films, and can solve the problem of improving the dielectric constant and dielectric loss of the fluorine-based resin/polyimide composition. Environmental problems such as adverse effects, to achieve the effect of reducing dielectric constant, avoiding pollution, and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

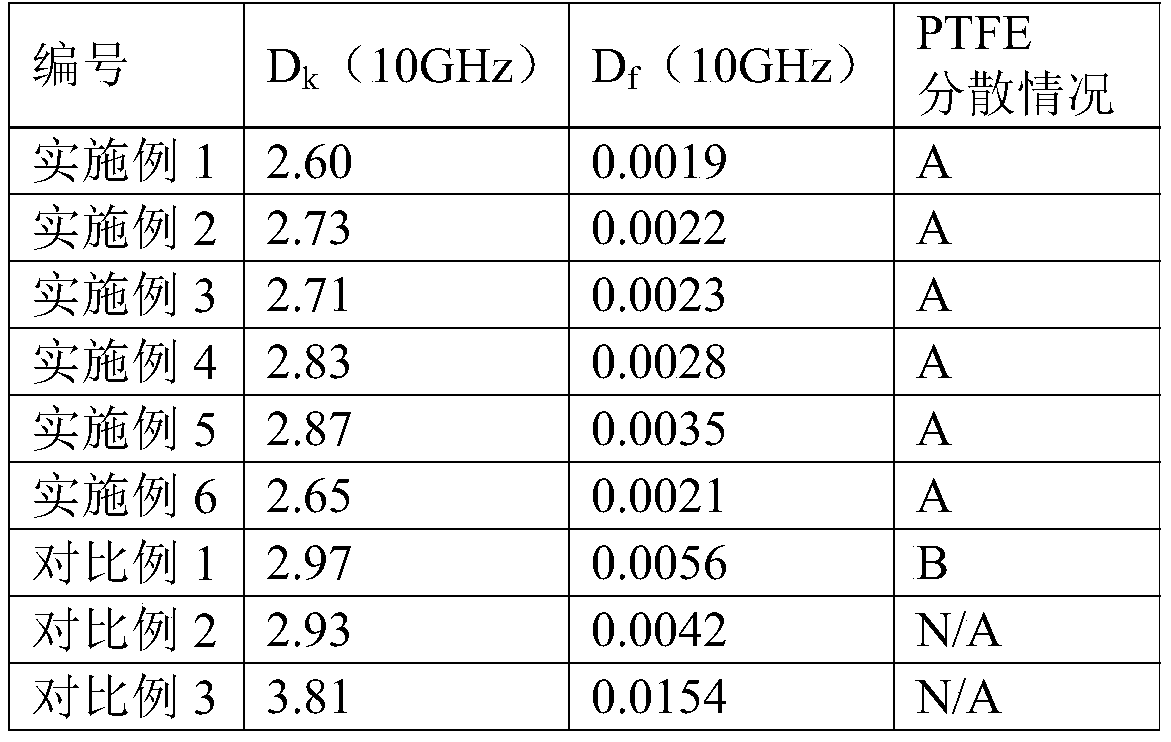

Examples

Embodiment 1

[0041] Add 6.0g of PTFE powder and 51g of NMP into the ball mill tank, carry out planetary ball milling at 500rpm for 24h, and obtain a dispersion in which PTFE powder is uniformly dispersed in NMP, and 3.6967g of 3,3'-dihydroxybenzidine (0.0171mol) and the above Add the dispersion into a four-neck flask, pass N 2 Protect, stir mechanically to completely dissolve 3,3'-dihydroxybenzidine, then add 5.3033g ODPA (0.0171mol) in 4 batches, with an interval of 15min between each batch, after adding all ODPA, continue stirring at 25°C for 24 hours, Add 7.9508g of heptafluorobutyryl chloride (0.0342mol), heat the reaction solution to 80°C, continue to stir and continue the reaction for 24 hours to obtain a fluoropolymer / polyamic acid combination solution, a fluoropolymer / polyamic acid combination solution Carry out defoaming treatment, after defoaming, apply it on a glass plate, and heat it in a vacuum oven at 100°C for about 30 minutes to remove most of the solvent, and then place it...

Embodiment 2

[0043] Add 6.0g of PTFE powder and 51g of NMP into the ball mill tank, carry out planetary ball milling at 500rpm for 24h, and obtain a dispersion in which PTFE powder is uniformly dispersed in NMP, and 3.6967g of 3,3'-dihydroxybenzidine (0.0171mol) and the above Add the dispersion into a four-neck flask, pass N 2 Protect, stir mechanically to completely dissolve 3,3'-dihydroxybenzidine, then add 5.3033g ODPA (0.0171mol) in 4 batches, with an interval of 15min between each batch, after adding all ODPA, continue stirring at 25°C for 24 hours, Add 3.9754g of heptafluorobutyryl chloride (0.0171mol), heat the reaction solution to 80°C, continue to stir and continue the reaction for 24 hours to obtain a fluoropolymer / polyamic acid combined solution, a fluoropolymer / polyamic acid combined solution Carry out defoaming treatment, after defoaming, apply it on a glass plate, and heat it in a vacuum oven at 100°C for about 30 minutes to remove most of the solvent, and then place it in a ...

Embodiment 3

[0045] Add 6.0g of PTFE powder and 51g of NMP into the ball mill tank, and carry out planetary ball milling at 500rpm for 24h to obtain a dispersion in which PTFE powder is uniformly dispersed in NMP, and 1.8769g of 3,3'-dihydroxybenzidine (0.0087mol), Add g 4,4'-ODA (0.0087mol) and the above dispersion into a four-necked flask, pass N 2 Protect, stir mechanically to dissolve 3,3'-dihydroxybenzidine and 4,4'-ODA completely, then add 5.3852g ODPA (0.0174mol) in 4 batches, with an interval of 15min between each batch, after all ODPA is added, put it at 25°C Continue to stir and continue to react for 24 hours, add 4.0452g of heptafluorobutyryl chloride (0.0174mol), heat the reaction solution to 80°C, continue to stir and continue to react for 24 hours, you can obtain a fluoropolymer / polyamic acid combination solution, fluoropolymer After degassing, apply it on a glass plate, and heat it in a vacuum oven at 100°C for about 30 minutes to remove most of the solvent, and then place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com