A kind of 1.70 refractive index polyurethane resin lens and preparation method thereof

A technology of polyurethane resin and refractive index, applied in the field of 1.70 refractive index polyurethane resin lens and its preparation, can solve the problems of low light transmittance, poor compatibility, complicated preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

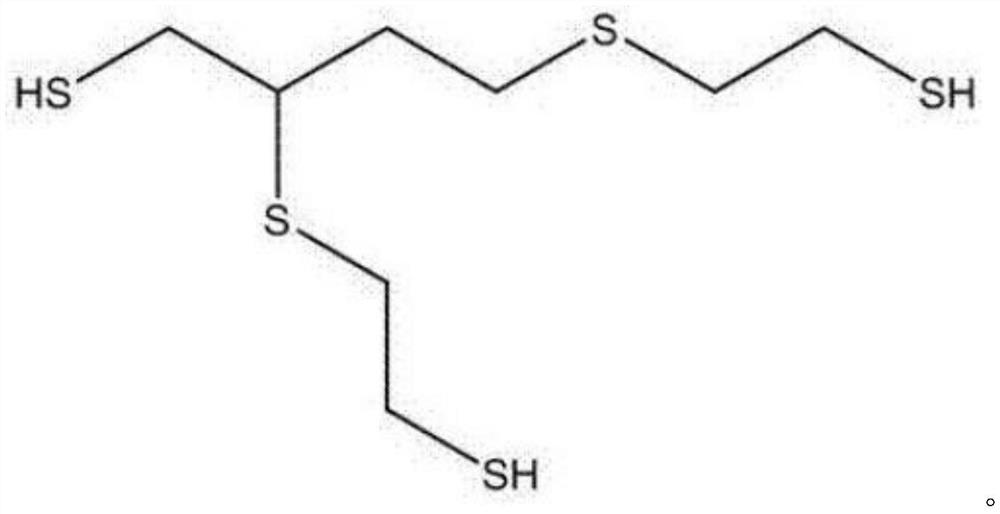

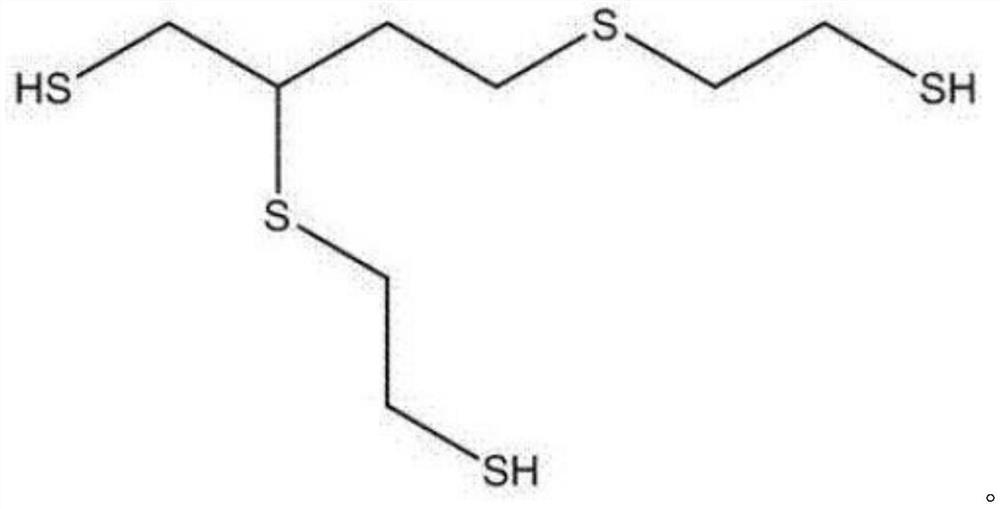

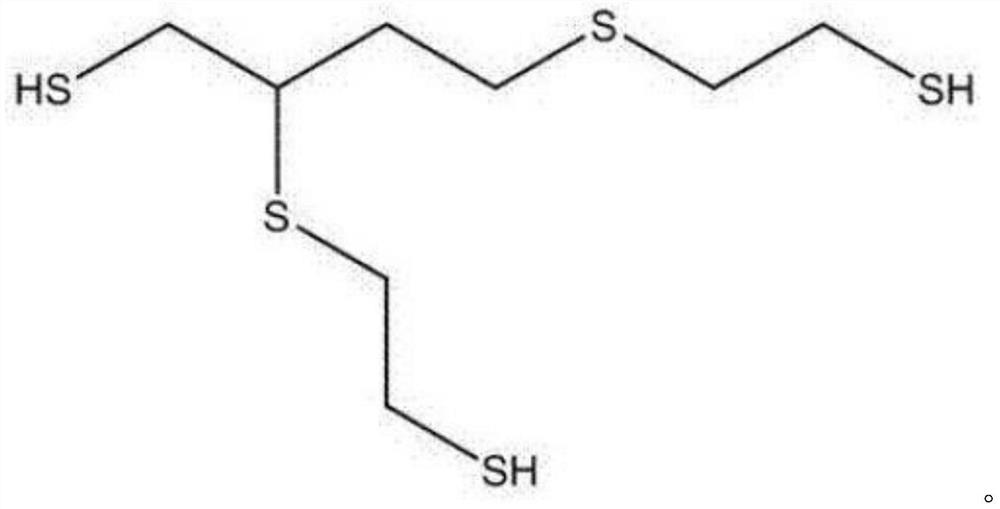

Image

Examples

example 1

[0037] Add β-cyclodextrin and sodium hydroxide solution with a mass fraction of 70% to the beaker at a mass ratio of 1:5, stir at room temperature for 10 minutes, and then add cyclodextrin with 10% cyclodextrin mass to the beaker. Trimethylammonium chloride, put the beaker in a water bath, heat up to 50°C, keep the temperature for 3 hours, filter and separate to obtain the filter residue, and dry to obtain cationic cyclodextrin; the cationic cyclodextrin prepared above and deionized After the water is mixed at a mass ratio of 1:10, stir at a high speed of 700r / min for 10 minutes to obtain a cationic cyclodextrin suspension, and transfer the cationic suspension into a three-necked flask with a dropping funnel and a stirrer; Move the flask into a water bath, heat up to 60°C, start the mixer, and stir at a speed of 200r / min. During the stirring process, add cyclodextrin four times the mass of cyclodextrin dropwise to the three-necked flask through the dropping funnel. Titanium ch...

example 2

[0041] Add β-cyclodextrin and sodium hydroxide solution with a mass fraction of 70% to the beaker at a mass ratio of 1:5, and stir at room temperature for 13 minutes, then add cyclodextrin mass 10% glycidyl Trimethylammonium chloride, put the beaker in a water bath, heat up to 55°C, keep the temperature for 3 hours, filter and separate to obtain the filter residue, and dry to obtain cationic cyclodextrin; the cationic cyclodextrin prepared above and deionized After mixing the water at a mass ratio of 1:10, stir at a high speed of 750r / min for 13 minutes to obtain a cationic cyclodextrin suspension, and transfer the cationic suspension into a three-necked flask with a dropping funnel and a stirrer; Move the flask into a water bath, heat up to 65°C, start the mixer, and stir at a speed of 250r / min. During the stirring process, add cyclodextrin tetrachloride, which is 7 times the mass of cyclodextrin, dropwise to the three-necked flask through the dropping funnel. Titanium chlori...

example 3

[0045] Add β-cyclodextrin and sodium hydroxide solution with a mass fraction of 70% to the beaker at a mass ratio of 1:5, stir at room temperature for 15 minutes, and then add cyclodextrin mass 10% glycidyl Trimethylammonium chloride, put the beaker in a water bath, heat up to 60°C, keep the temperature for 4 hours, filter and separate to obtain the filter residue, and dry to obtain the cationic cyclodextrin; the cationic cyclodextrin prepared above and deionized After the water is mixed at a mass ratio of 1:10, stir at a high speed of 800r / min for 15 minutes to obtain a cationic cyclodextrin suspension, and transfer the cationic suspension into a three-necked flask with a dropping funnel and a stirrer; Move the flask into a water bath, heat up to 70°C, start the mixer, and stir at a speed of 300r / min. During the stirring process, add tetracycline 8 times the mass of cyclodextrin dropwise to the three-necked flask through the dropping funnel. Titanium chloride, the dropping ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com