Wet screening device and graphite ore short-process purification method comprising wet screening

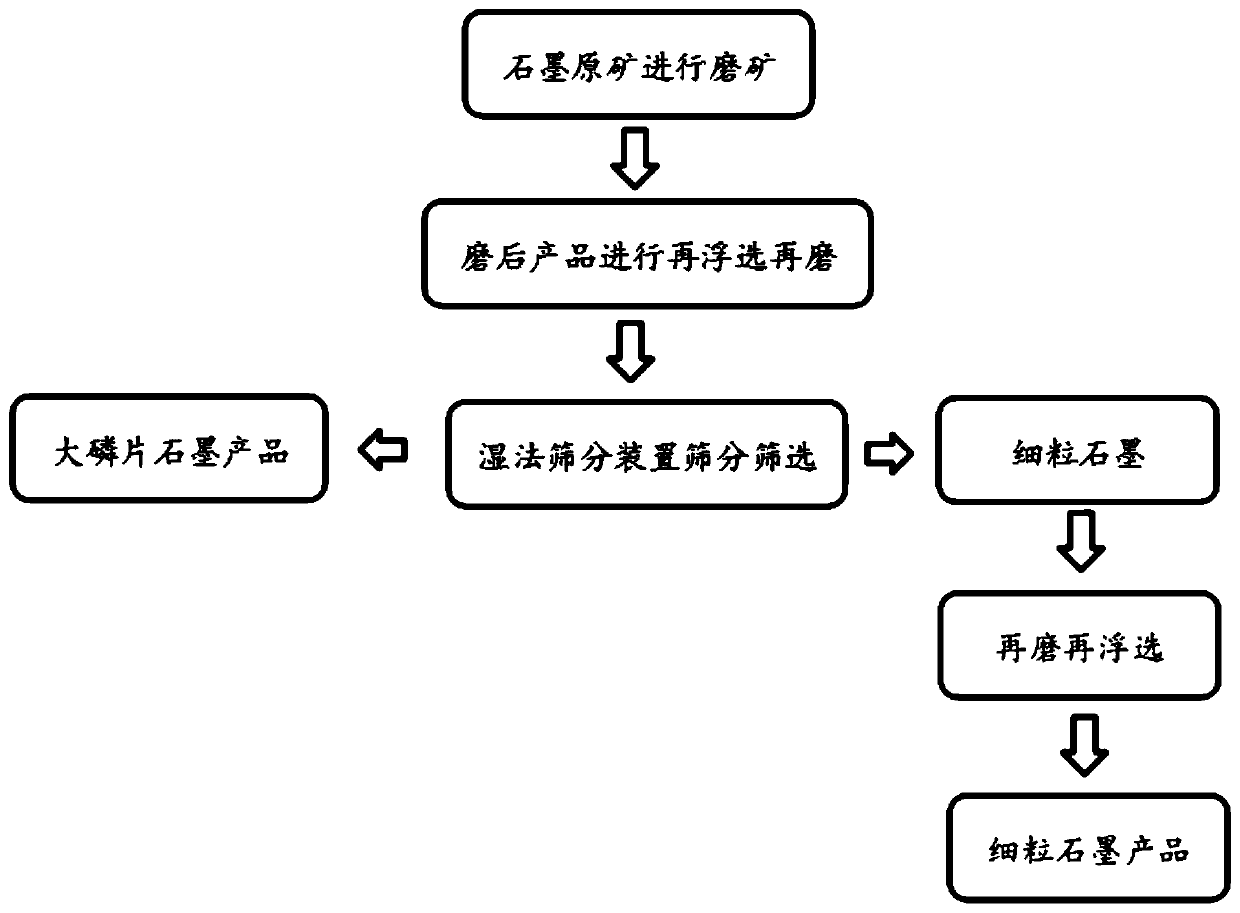

A technology of wet screening and screening device, applied in wet separation, graphite, chemical instruments and methods, etc., can solve the problems of small graphite flakes, long process, high cost, reduce clogging, improve quality, and increase production. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This Example 1 provides a short-process purification method for graphite ore containing wet screening. A graphite ore in Luobei, Heilongjiang is dried, crushed, sieved, shrunk, and dried. The raw ore has a fixed carbon content of 13%. The screen of the sieving device is a single layer with a screen hole diameter of 0.15mm. The embodiment specifically includes the following steps:

[0057] After coarsely selecting 400g of graphite ore, perform four ball milling and four flotation beneficiation processes. The total regrind time is 15 minutes. The flotation product is sieved for 10 minutes by the sieving device (screen aperture 0.15mm), with large scales on the screen Graphite is used as concentrate I; fine-grained graphite under the sieve enters the lower mill for re-grinding, and the fine particles after grinding are subjected to flotation. The process uses 4 grinding and 5 flotation, and the obtained fine graphite is used as concentrate II. After the graphite purification...

Embodiment 2

[0066] This Example 2 provides a short-process purification method for graphite ore containing wet screening, which adopts a process of grinding-flotation-sieving, and fine-grained graphite re-grinding and re-flotation. A certain graphite ore in Luobei, Heilongjiang is obtained by drying, crushing, sieving, shrinking, and drying. The fixed carbon content of the raw ore is 13%. The screen of the sieving device is a single layer with a screen hole diameter of 0.15mm.

[0067] The short-process purification method of graphite ore by wet screening provided in this embodiment specifically includes the following steps:

[0068] Take 400g of raw graphite ore for 8 minutes, and carry out four ball milling and four flotation (four milling and four flotation can produce sufficient quantity and grade of large flake graphite). The total regrind time is 21 min. The flotation product adopts the sieve. The separation device (screen mesh aperture 0.15mm) screens for 10 minutes, the large flake gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com