Preparation method and application of metal surface anticoagulation layer

A metal surface, anti-coagulation technology, applied in the field of metal surface treatment, can solve the problems of difficult anti-coagulation treatment, no evaluation of anti-coagulation effect, etc., and achieve the effect of not easy to fall off and high anti-coagulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of metal surface anticoagulation coating of the present invention comprises the following steps:

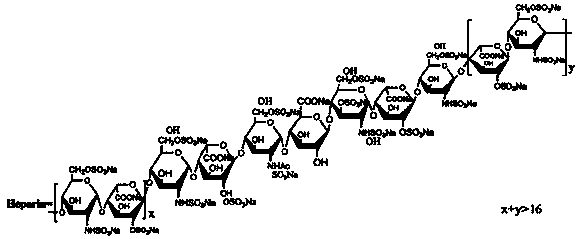

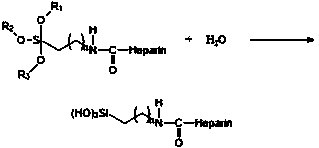

[0027] Step 1, preparation of siloxane-based heparin: the reaction between the isocyanate-based siloxane and the heparin occurs between the isocyanate group of the isocyanate-based siloxane and the hydroxyl group in the heparin, in order to ensure that the heparin is completely siloxane Alkylation should make the isocyanate group excess, that is, the molar ratio of isocyanate siloxane to heparin is greater than 1:1; the reaction temperature is controlled at 40°C-60°C; the reaction time is controlled for 4-6 hours. Obtain the heparin of silicon oxygen alkylation, concrete reaction formula is as follows:

[0028]

[0029]

[0030] Wherein: R1, R2, R3 are alkyl groups, and the alkyl groups are preferably -CH3, -CH2CH3

[0031] n is an integer greater than 0, preferably an integer between 2-10

[0032] Step 2, preparation of silanized heparin: pr...

Embodiment 1-3

[0040] Siloxylation of heparin: Dissolve 15g of heparin in 100mL of anhydrous THF, place in a three-necked bottle, stir evenly and pour into dry N 2 , heated to 60°C; 0.5g of 3-isocyanatopropyltriethoxysilane was dissolved in 20mL of anhydrous THF, placed in a dropping funnel, slowly added dropwise into a three-necked bottle, and the dropwise addition was completed in 30 minutes. Continue to maintain the temperature reaction for 4h. Precipitate twice with anhydrous ether and dry in a vacuum oven for 24 hours. A siloxanated heparin is obtained.

[0041] Preparation of siliconized heparin: Add siliconized heparin and purified water into a 500ml beaker according to the weight shown in Table 1, stir evenly at room temperature and fully dissolve, and use the obtained solution after standing for 24 hours.

[0042] Table 1 The formula of the siliconized heparin solution of different concentrations

[0043]

[0044] Coating preparation on the metal surface: ultrasonically clean ...

Embodiment 4

[0049] Siloxylation of heparin: Dissolve 15g of heparin in 100mL of anhydrous THF, place in a three-necked bottle, stir evenly and pour into dry N 2 , heated to 60°C; dissolve 0.65g of octyltriethoxysilane isocyanate in 20mL of anhydrous THF, put it in the dropping funnel, slowly drop it into the three-necked bottle, and drop it in 30 minutes, continue to maintain the temperature Reaction 4h. Precipitate twice with anhydrous ether and dry in a vacuum oven for 24 hours. A siloxanated heparin is obtained.

[0050] Preparation of siliconized heparin: Add 5g of siliconized heparin into a 500ml beaker, then add 95g of purified water, stir evenly and fully dissolve at room temperature, and use the obtained solution after standing for 24 hours.

[0051] Coating preparation on the metal surface: ultrasonically clean the titanium alloy sheet in absolute ethanol for 10 minutes, and dry it in a blast drying oven at 80°C for 2 hours, and then use a plasma gun to clean the surface, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com