Preparation method of antioxidant black phosphorus nanosheet

A nanosheet, anti-oxidation technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of insufficient stability, high cost, complicated operation process, etc., and achieve low cost, oxidation prevention, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

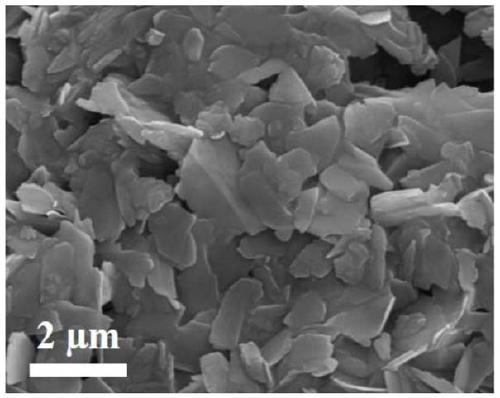

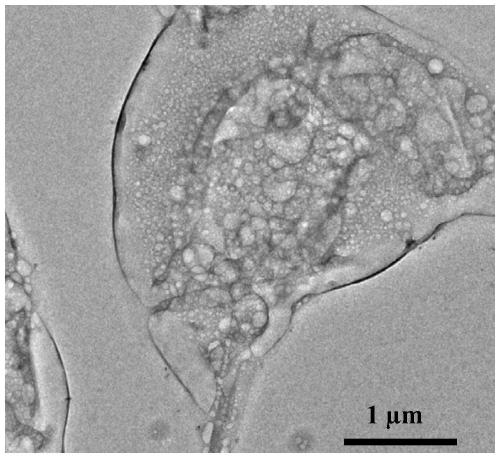

[0034] Step 1: Preparation of black phosphorus nanosheets with a diameter of 1-100nm: take the BP bulk material and disperse it in anhydrous nitrogen-nitrogen dimethylformamide / ethanol solution with a mass concentration of 0.5mg mL -1 , deoxygenated by argon for 0.5h, and ultrasonicated for 30h in an ice bath (KD250, 250W). Let stand overnight to remove the unstripped BP precipitate, centrifuge the supernatant suspension at 12000rpm for 20min to remove nitrogen nitrogen dimethylformamide solvent molecules, wash the precipitate with ethanol, and dry it in vacuum. At the same time, 7.59 g of triethylamine (TEA) was dissolved in 50 mL of CH 2 Cl 2 Prepare a solution of the alkanylamine in .

[0035] Step 2: Take 50 mg of black phosphorus nanosheets and disperse them in 50 mL of anhydrous DMF solution, add the above-mentioned alkane amine solution, and mix evenly by stirring for 1 h.

[0036] Step 3: After sealing the above mixed solution, heat it to 100° C. under the protectio...

Embodiment 2

[0039] Step 1: Preparation of black phosphorus nanosheets with a diameter of 1-100nm: take the BP body material and disperse it in anhydrous formamide / ethanol solution with a mass concentration of 0.5mg mL -1 , deoxygenated by argon for 0.5h, and ultrasonicated for 30h in an ice bath (KD250, 250W). Let stand overnight to remove the unstripped BP precipitate, centrifuge the supernatant suspension at 12000rpm for 20min to remove nitrogen nitrogen dimethylformamide solvent molecules, wash the precipitate with ethanol, and dry it in vacuum. At the same time, 9.59 g of diethylmethylamine (DEMA) was dissolved in 50 mL of CH 2 ClCH 2 Prepare a solution of the alkylamine in Cl.

[0040] Step 2: Take 50 mg of black phosphorus nanosheets and disperse them in 50 mL of anhydrous benzyl alcohol solution, add the above-mentioned solution for preparing alkane amine, and mix evenly by ultrasonication for 1 h.

[0041] Step 3: Heat the above mixture to 140° C. under nitrogen protection, and...

Embodiment 3

[0045] Step 1: Preparation of black phosphorus nanosheets with a diameter of 1-100nm: take the BP body material and disperse it in anhydrous nitrogen methyl pyrrolidone solution with a mass concentration of 0.5mg mL -1 , deoxygenated by argon for 0.5h, and ultrasonicated for 30h in an ice bath (KD250, 250W). Stand overnight to remove the unstripped BP precipitate, centrifuge the upper layer suspension at 12000rpm for 20min to remove NMP solvent molecules, wash the precipitate with ethanol, and dry it in vacuum. Meanwhile, 7.59 g of triethylamine (TEA) was dissolved in 50 mL of CH 2 Cl 2 Prepare a solution of the alkanylamine in .

[0046] Step 2: Take 50 mg of black phosphorus nanosheets and disperse them in 50 mL of anhydrous DMF solution, add the above-mentioned solution for preparing alkane amine, and mix evenly by ultrasonication for 1 h.

[0047] Step 3: Heat the above mixture to 90° C. under nitrogen protection, and reflux for 12 h.

[0048] Step 4: Allow the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com