Low-temperature oxidation curing process of secondary particles

A technology of secondary granulation and curing process, which is applied in the granulation of special adhesives, the method of granulating raw materials, and the granulation in static tanks/tanks, etc. It can solve problems such as difficulty in meeting application requirements and achieve excellent curing effect. , the effect of low energy consumption and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

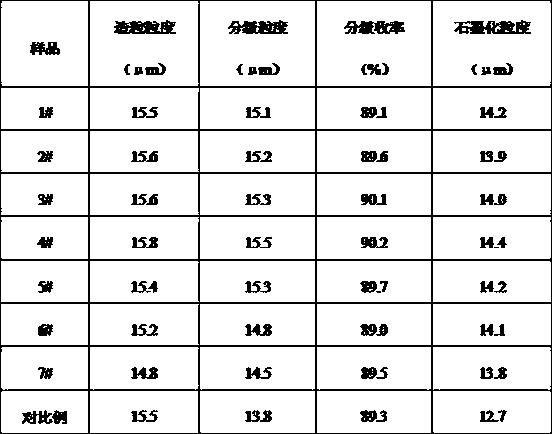

Examples

Embodiment 1

[0032] Feed the secondary particles ① into the cooling kettle. The cooling kettle maintains a nitrogen atmosphere, the stirring speed is 50rpm, the cooling method is cooling by circulating heat transfer oil, and the cooling speed is 120°C / min.

[0033] When the indicated temperature of the material drops to 320°C, close the feed valve and discharge valve of the circulating oil in turn; keep the cooling rate at 30°C / min, and when the temperature drops to 250°C, close the nitrogen inlet valve and open the oxygen inlet valve ; After the material is cooled to room temperature, the 1# sample can be obtained.

Embodiment 2

[0035] Feed the secondary particles ① into the cooling kettle. The cooling kettle maintains an argon atmosphere, the stirring speed is 60rpm, the cooling method is cooling by circulating heat transfer oil, and the cooling speed is 250°C / min.

[0036] When the indicated temperature of the material drops to 320°C, close the feed valve and discharge valve of the circulating oil in turn; keep the cooling rate at 30°C / min, and when the temperature drops to 250°C, close the nitrogen inlet valve and open the oxygen inlet valve ; When the material is cooled to room temperature, the 2# sample can be obtained.

Embodiment 3

[0038] Feed the secondary particles ② into the cooling kettle. The cooling kettle maintains a nitrogen atmosphere, the stirring speed is 70rpm, the cooling method is cooling by circulating heat transfer oil, and the cooling speed is 140°C / min.

[0039] When the indicated temperature of the material drops to 320°C, close the feed valve and discharge valve of the circulating oil in turn; keep the cooling rate at 30°C / min, and when the temperature drops to 250°C, close the nitrogen inlet valve and open the oxygen inlet valve ; When the material is cooled to room temperature, the 3# sample can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com