Planar mask machine

A mask and plane technology, applied in the field of mask machines, can solve problems such as low degree of automation, low production capacity, and inability to cope with the huge demand for masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further described in conjunction with the following examples.

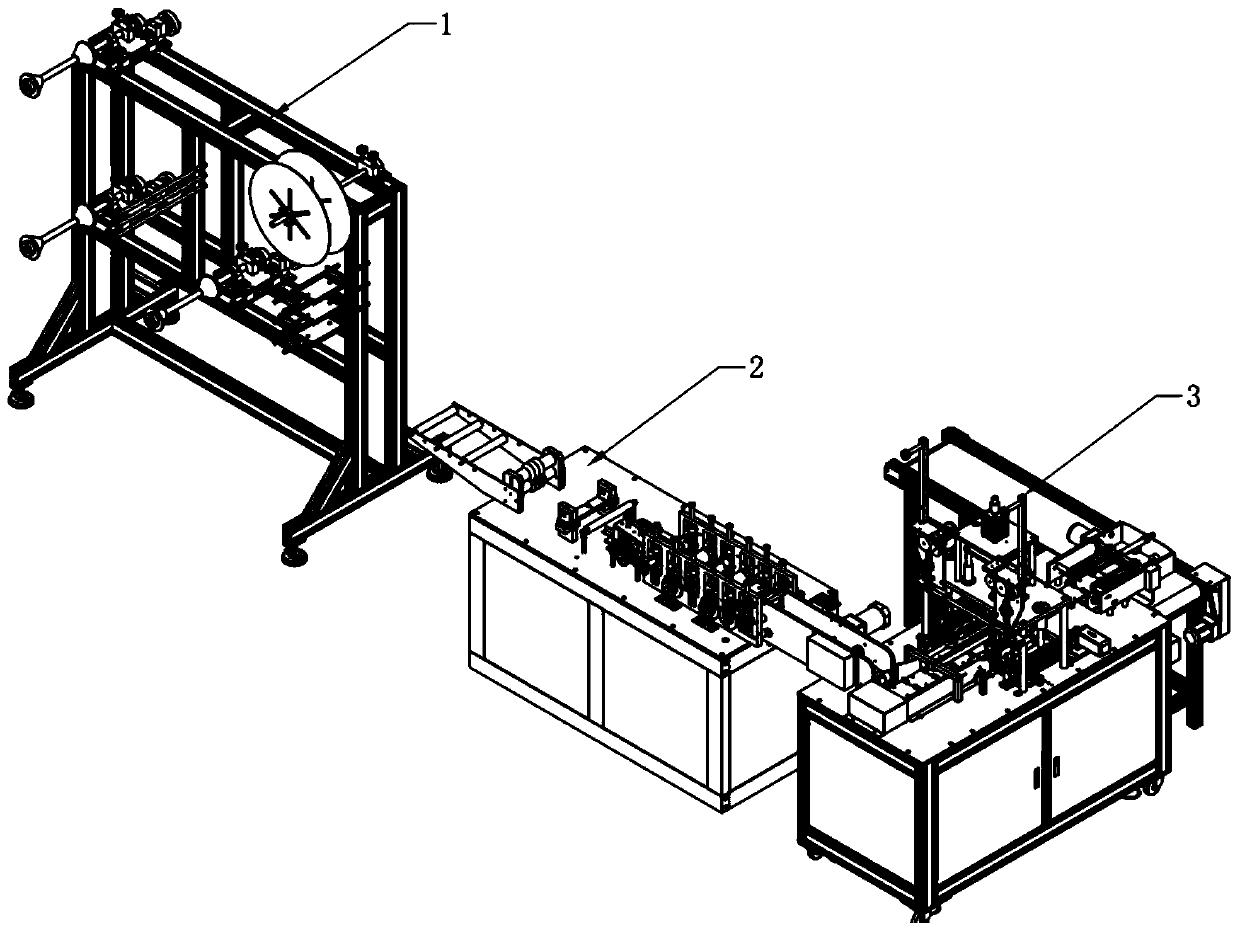

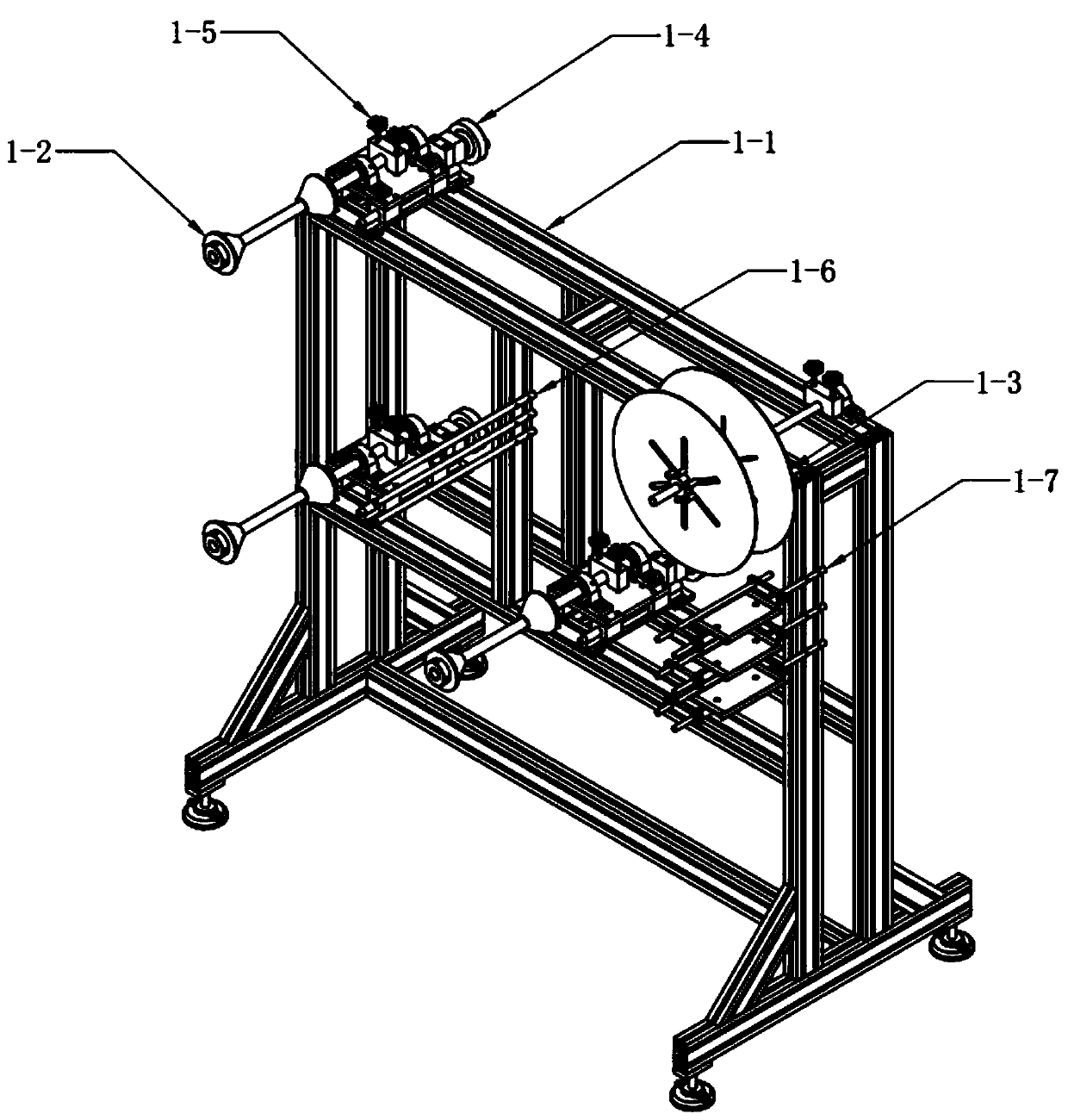

[0058] The specific embodiment of a kind of flat mask machine of the present invention, as Figure 1-Figure 30 As shown, it includes a discharge rack 1, a mask body film making machine 2 and an earband welding machine 3. One end of the mask body film making machine 2 is connected to the discharge rack 1, and the other end of the mask body film making machine 2 is connected to Earband fusion machine 3. The unwinding frame 1 includes a main frame 1-1 and a distribution rod group 1-2 for hanging coiled materials, a nose strip reel 1-3, and a cloth adjusting device 1-1 arranged on the main frame 1-1. 4. Coil braking device 1-5, material guide rod 1-6 and guide rod group 1-7 for guiding raw material loading, the guide rod group 1-7 is provided with multiple and stacked One side of the main frame 1-1 is close to the film making machine 2 of the mask body.

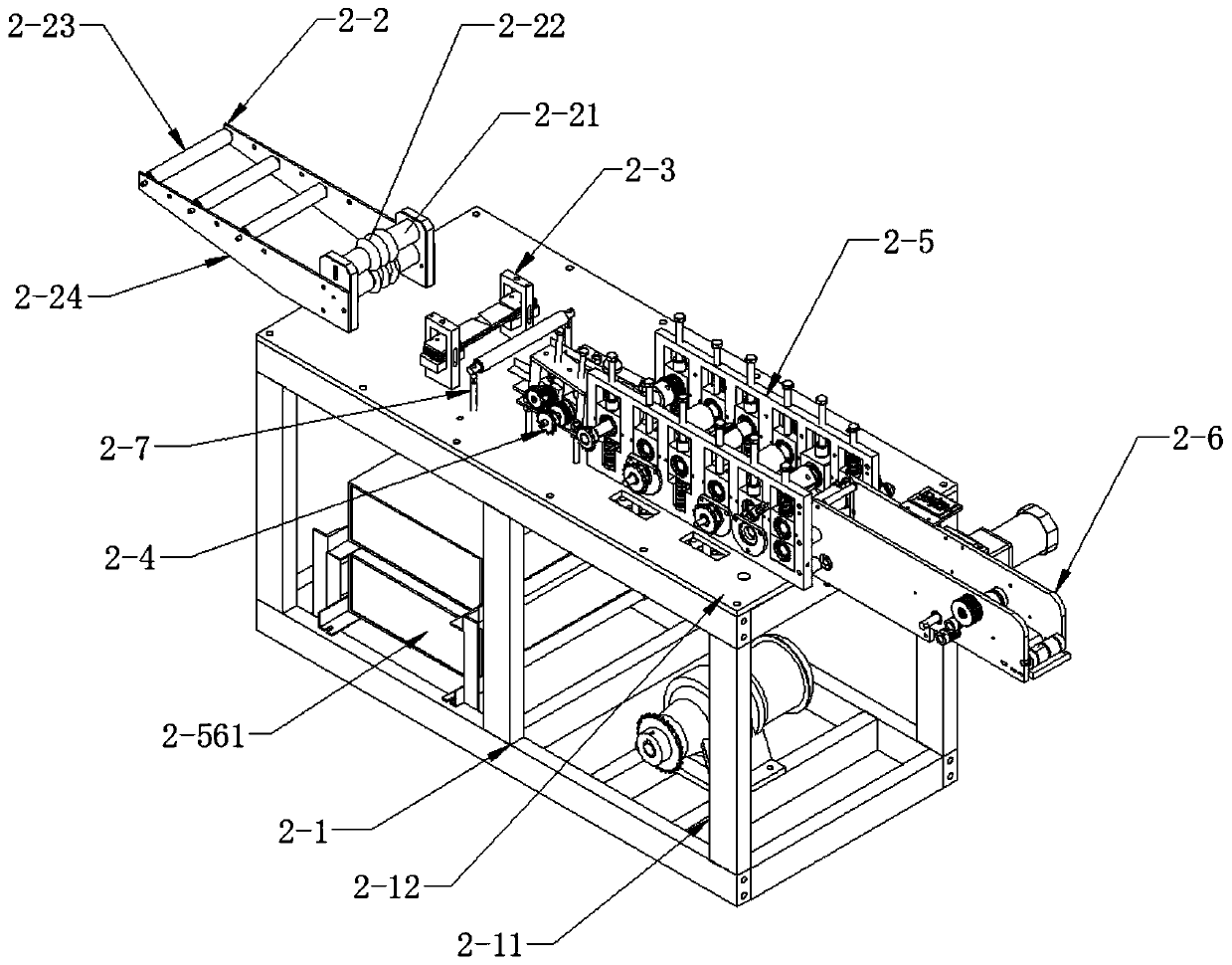

[0059] The mask body film ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com