Semiconductor laser integrated with slow optical waveguide on chip

A laser and optical waveguide technology, which is applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve problems such as poor device performance, increased optical field mode loss, and poor practicability, achieving low cost and expanding light output Aperture, the effect of reducing the divergence angle of the far field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

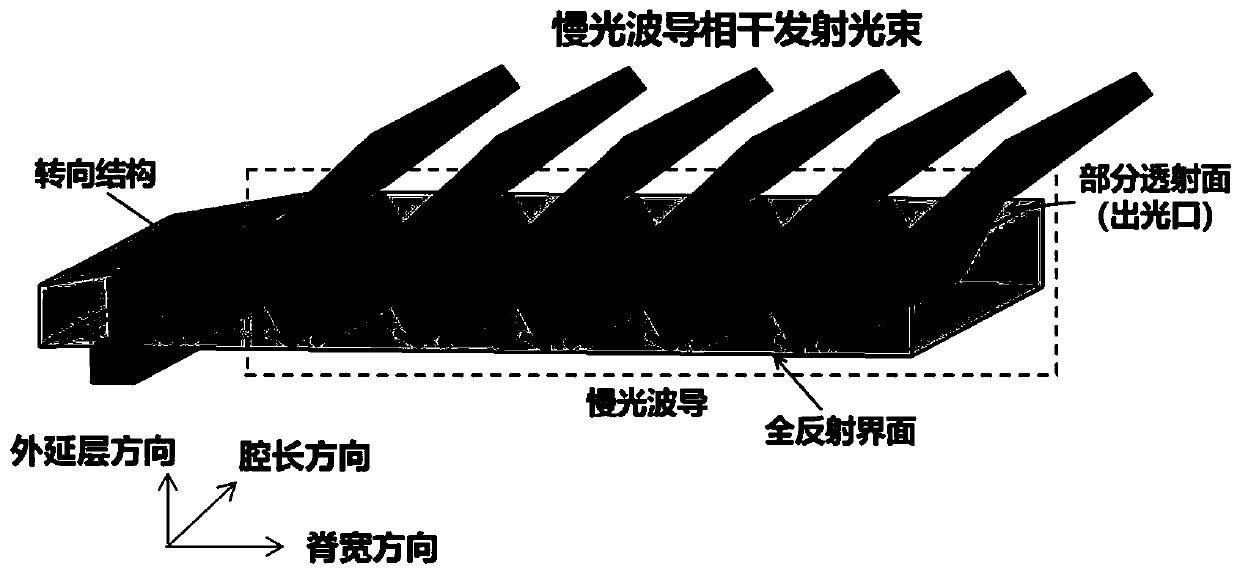

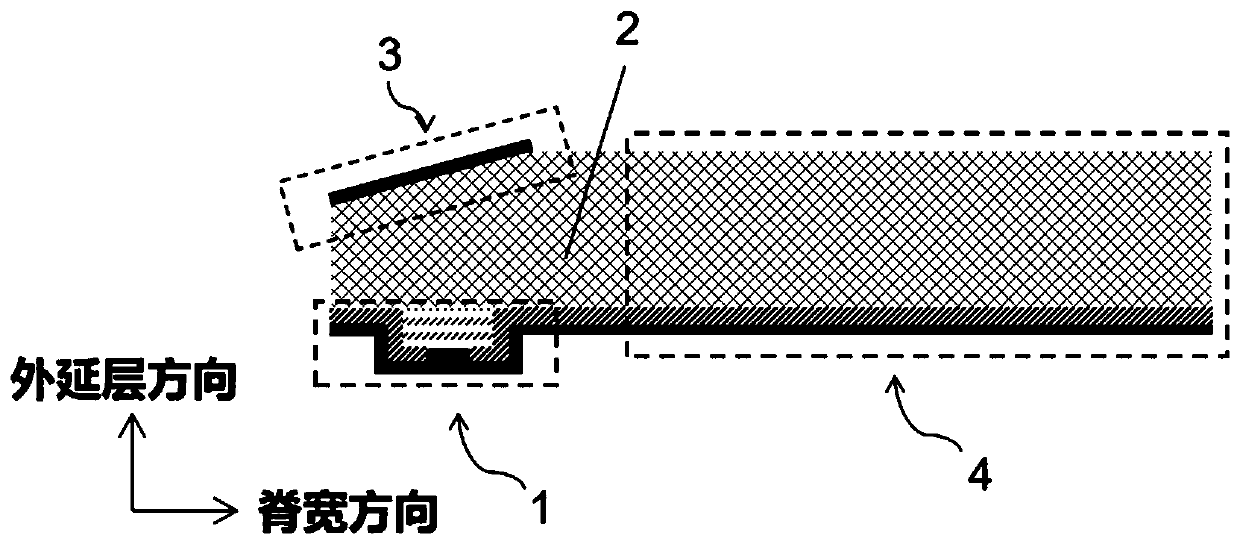

[0062] refer to Figure 10 , and combined with Figure 6 (a) and Figure 9 (a), in this example, the on-chip semiconductor laser with integrated slow light waveguide includes: laser active region 1, substrate 2, steering structure 3 and slow light waveguide structure 4. Wherein: the laser active region 1 is located on one side of the substrate 2 in the direction of the epitaxial layer, the steering structure 3 is located on the other side of the substrate in the direction of the epitaxial layer, and the slow optical waveguide structure 4 is located on the side of the substrate along the direction of the ridge width.

[0063] The laser active region 1 includes a ridge waveguide 11 , an electrical isolation layer 12 , a metal layer 14 and an electrical injection window 13 . Ridge waveguide 11 is the core area of laser light emission, which is prepared by metal oxide chemical vapor deposition MOCVD or molecular beam epitaxy MBE equipment. According to the order of film depos...

Embodiment 2

[0071] refer to Figure 11 , and combined with Figure 6 (b) and Figure 9 (b), in this example, the on-chip semiconductor laser with integrated slow light waveguide includes: laser active region 1 and substrate 2, steering structure 3 and slow light waveguide structure 4. The laser active region 1 is located on one side of the epitaxial layer of the substrate 2, the steering structure 3 is located on the other side of the epitaxial layer of the substrate, and is symmetrically distributed with the laser active region structure relative to the substrate 2, and the slow optical waveguide Structure 4 is located on one side of the substrate along the ridge width direction.

[0072] The laser active region 1 includes a ridge waveguide 11 , an electrical isolation layer 12 , a metal layer 14 and an electrical injection window 13 . Ridge waveguide 11 is the core area of laser light emission, which is prepared by metal oxide chemical vapor deposition MOCVD or molecular beam epita...

Embodiment 3

[0080] refer to Figure 12 , and combined with Figure 7 (a) and Figure 9 (a), the semiconductor laser integrated with slow light waveguide on chip in this example includes: laser active region 1, substrate 2, steering structure 3 and slow light waveguide structure 4. The laser active region 1 is located on one side of the substrate 2 in the direction of the epitaxial layer, the steering structure 3 is located on the other side of the substrate 2 in the direction of the epitaxial layer, and is symmetrical to the structure of the laser active region relative to the substrate 2, and the distribution of slow light The waveguide structure 4 is located on one side of the substrate 2 along the ridge width direction.

[0081] The laser active region 1 includes a ridge waveguide 11 , an electrical isolation layer 12 , a metal layer 14 and an electrical injection window 13 . Ridge waveguide 11 is the core area of laser light emission, which is prepared by metal oxide chemical vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com