Visual test device and method for crushing coral sand around pile in pile sinking process

A test device, coral sand technology, used in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc., can solve problems such as laying stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

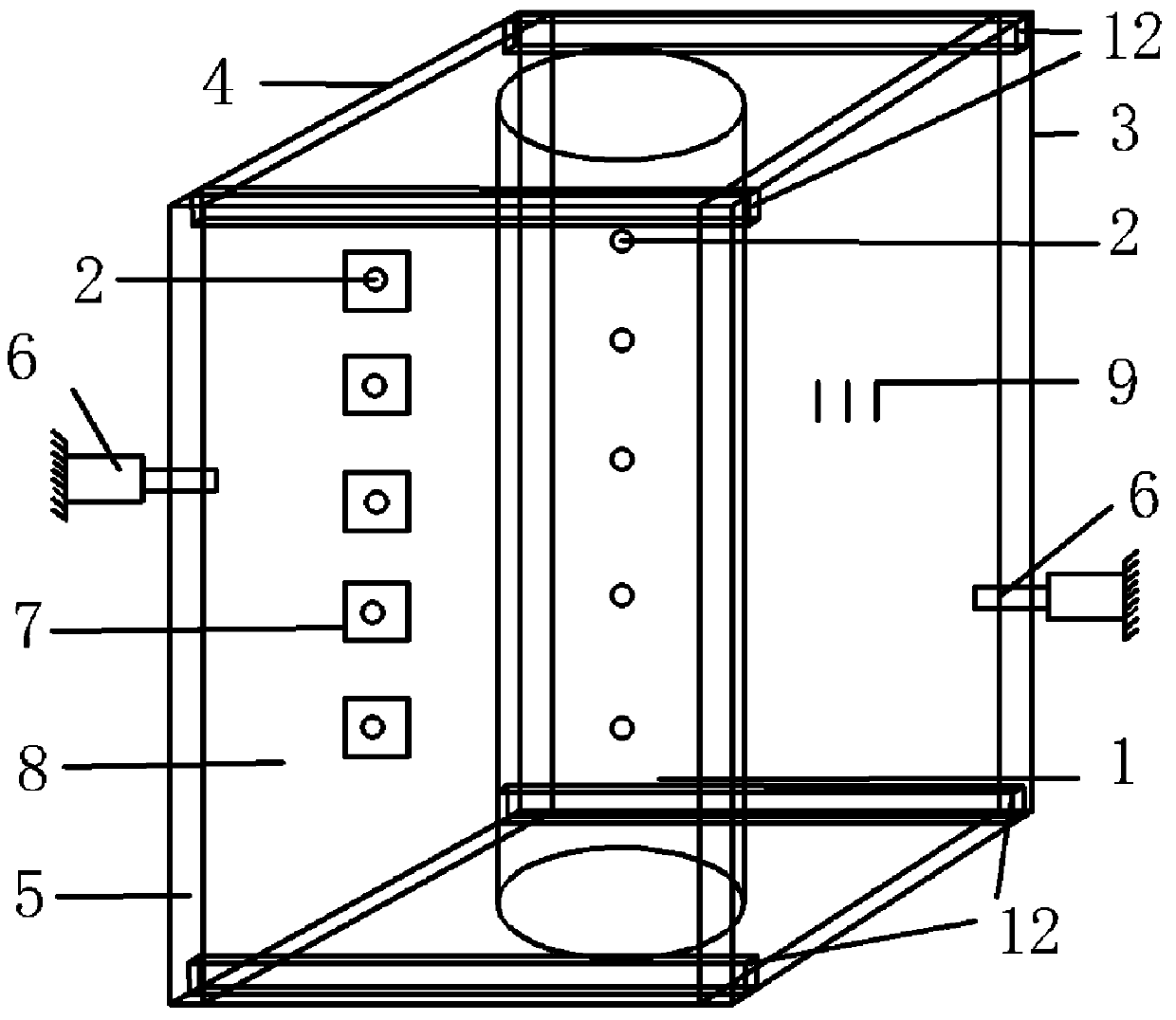

[0047] see Figure 1-5 , a visual test device for broken coral sand around piles in the pile sinking process, which includes three different structural forms, wherein the first structural form includes a cuboid test box 3, and a top cover 4 is fixed on the top of the cuboid test box 3 , wherein two paired side walls of the cuboid test box 3 are movable plates, the outside of the movable plate is provided with a jack 6 for applying pressure to it, and a window 7 is installed on the side wall of the movable plate , the different heights of the window 7 and the prefabricated pile 1 are respectively provided with a camera 2 for recording the test process; A multi-layer coral sand layer 8 is filled and laid, and pressure sensing sheets 9 are arranged at equal intervals in two different directions, transverse and radial, on the same plane of the coral sand layer 8 .

[0048] Further, the movable plate matches with the chute 12 on the cuboid test box 3 .

[0049] Further, a filling...

Embodiment 2

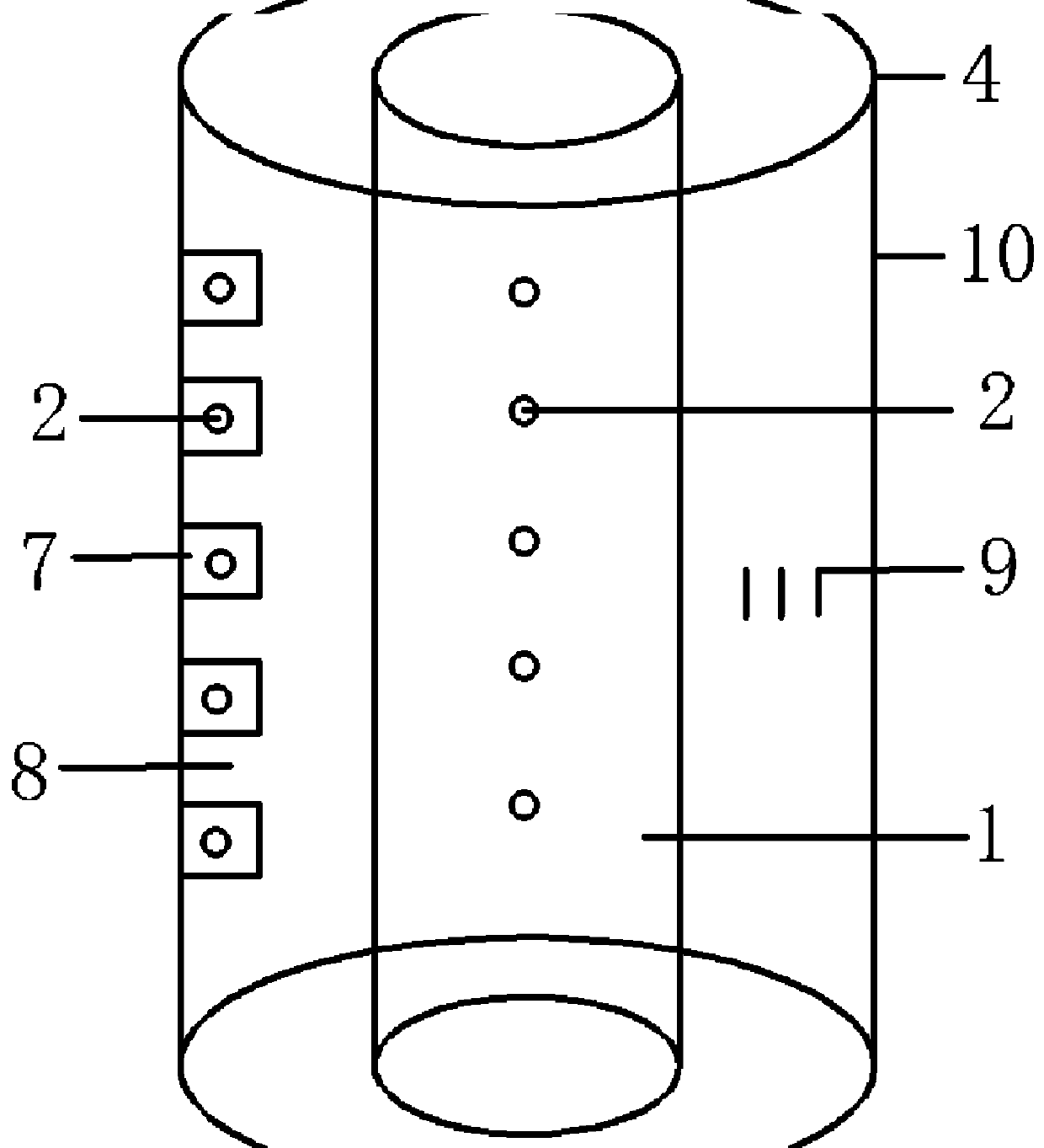

[0053] The second structure form comprises a hollow cylinder 10, a filling pad 5 is installed on the inner wall of the hollow cylinder 10, a top cover 4 is fixedly installed on the top of the hollow cylinder 10, and the inside of the hollow cylinder 10 is set There are prefabricated piles 1, and a plurality of equidistant windows 7 are arranged on the side wall of the hollow cylinder 10, and the inside of the hollow cylinder 10 is filled with multiple layers of coral sand layers 8 of different colors through laying. On the same plane of the coral sand layer 8 , pressure sensing sheets 9 are arranged at equal intervals in two different directions, transverse and radial, and a plurality of cameras 2 are arranged at equal intervals on the window 7 and the prefabricated pile 1 .

Embodiment 3

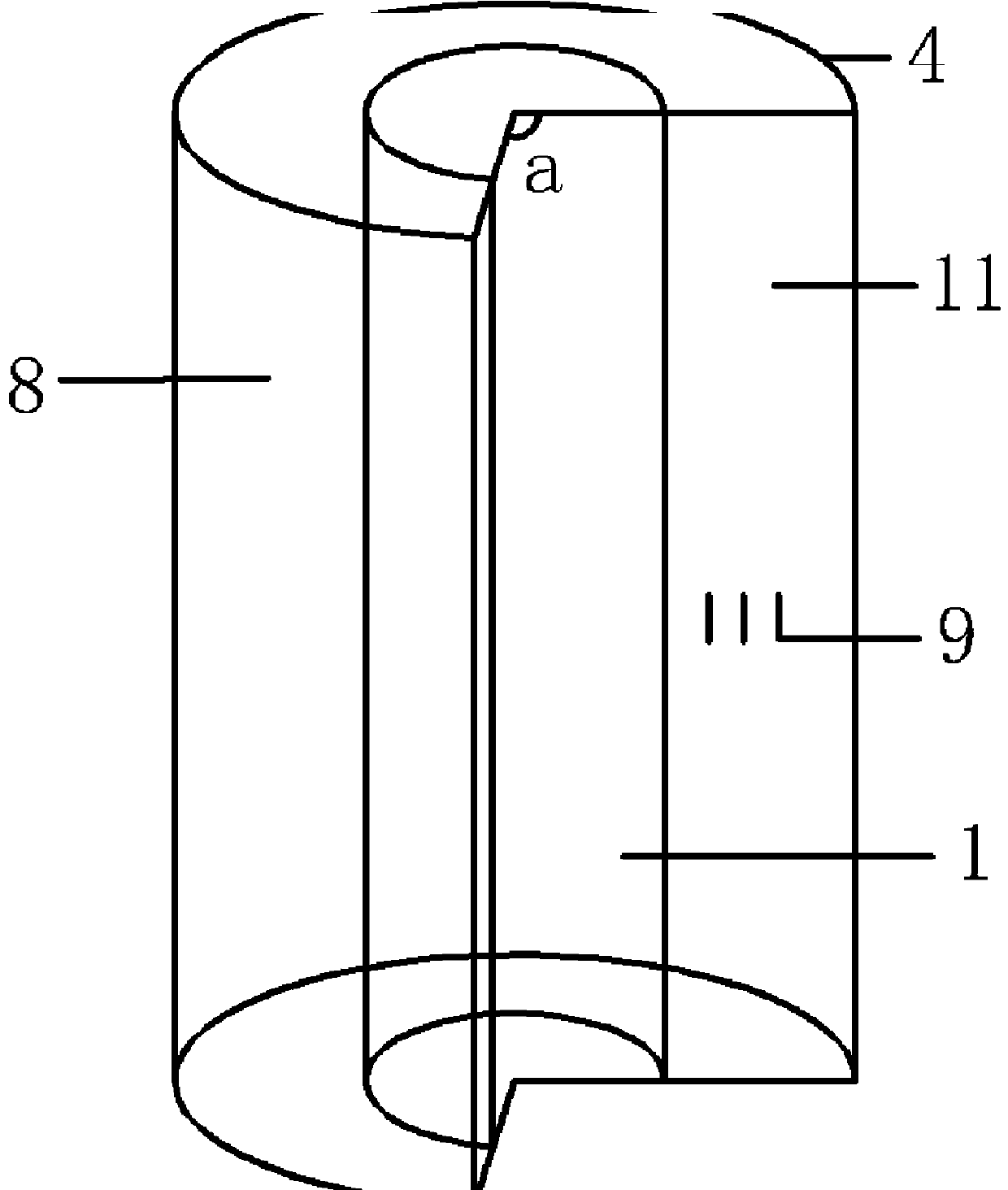

[0055] The third structural form includes a fan-shaped cylindrical barrel 11, the top of which is fixedly mounted with a matching top cover 4, and the inside of the fan-shaped cylindrical barrel 11 is provided with prefabricated piles 1 cut into a fan shape. The inside of the fan-shaped cylindrical barrel 11 is filled with multiple layers of coral sand layers 8 of different colors, and the same plane of the coral sand layer 8 is arranged with pressure sensing sheets 9 at equal intervals in two different directions, transverse and radial. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com