High-temperature high-pressure less-water dyeing process

A high-temperature, high-pressure, high-tech technology, applied in the field of dyeing, can solve the problems of difficult treatment, heavy environmental pollution, and high technical requirements, and achieve the effects of recycling, reducing the number of washings, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] AF-R orange (azo type)

[0032] Test cloth: polyester T100D / 144F semi-dull

[0033] Disperse dye: AF-R orange Liquor ratio: 1:20

[0034] Test equipment: Rapid ECO-24

[0035] Test process: high temperature, high pressure and less water dyeing process:

[0036] Weighing (disperse dye 2% owf, high temperature leveling agent SY-WS 1% owf) → chemical material → dyeing (pH value 5, heat up to 130°C at 1.8°C / min and keep it for 40min, then cool down to 80°C) → Add reduction cleaning agent (3% owf) → reduction cleaning (pH value 5, heat up to 90°C at 1.8°C / min and keep it warm for 25min, then cool down to 80°C) → iron dry

[0037] In the water-less dyeing process, the residual liquid after reduction and cleaning is recycled again and used as water for the next dyeing, and the cycle is ten times.

[0038] The relevant performance test results are shown in Table 1.

Embodiment 2

[0046] FB red (anthraquinone type)

[0047] Test cloth: polyester T100D / 144F semi-dull

[0048] Disperse dye: FB red bath ratio: 1:50

[0049] Test equipment: Rapid ECO-24

[0050] Test process: less water dyeing process:

[0051] Weighing (disperse dye 2% owf, high temperature leveling agent SY-WS 1% owf) → chemical material → dyeing (pH value 5, heat up to 130°C at 1.8°C / min and keep it for 40min, then cool down to 80°C) → Add reduction cleaning agent (3% owf) → reduction cleaning (pH value 5, heat up to 90°C at 1.8°C / min and keep it warm for 25min, then cool down to 80°C) → iron dry

[0052] In the water-less dyeing process, the residual liquid after reduction and cleaning is recycled again and used as water for the next dyeing, and the cycle is ten times.

[0053] The relevant performance test results are shown in Table 2.

Embodiment 3

[0062] color matching navy blue

[0063] Test cloth: polyester T100D / 144F semi-dull

[0064] dye:

[0065] C-BN Black 0.6%

[0066] S-5BL Ruby 0.2%

[0067] ES-BR Deep Blue 1.2%

[0068] Bath ratio 1:20

[0069] Test equipment: Rapid ECO-24

[0070] Test process: less water dyeing process:

[0071] Weighing (disperse dye 2% owf, high temperature leveling agent SY-WS 1% owf) → chemical material → dyeing (pH value 5, heat up to 130°C at 1.8°C / min and keep it for 40min, then cool down to 80°C) → Add reduction cleaning agent (3% owf) → reduction cleaning (pH value 5, heat up to 90°C at 1.8°C / min and keep it warm for 25min, then cool down to 80°C) → iron dry

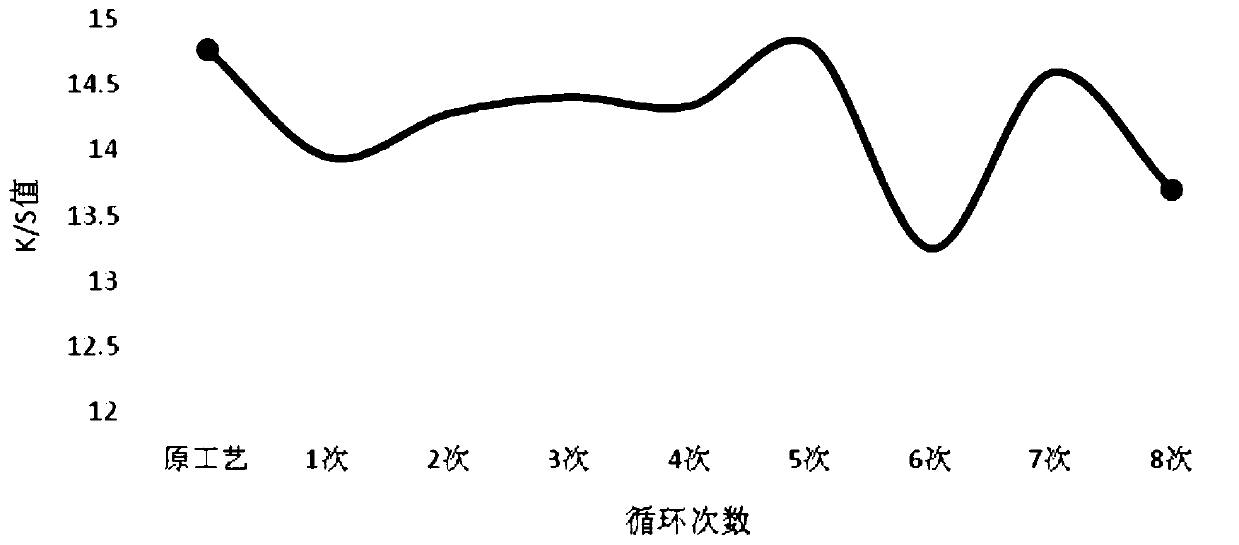

[0072] In the water-less dyeing process, the residual liquid after reduction and cleaning is recycled again and used as water for the next dyeing, and the cycle is eight times.

[0073] The relevant performance test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com