Doped ab3 type rare earth-samarium-nickel hydrogen storage alloy, battery and preparation method

A technology of hydrogen storage alloys and rare earths, which is applied in the direction of nickel storage batteries, battery electrodes, alkaline storage batteries, etc., can solve the problems of low capacity retention and achieve high capacity retention, high discharge capacity, and fewer activation cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation process of the solid alloy can be a flake process or a casting process. Alloy flakes were prepared by flake flakes. The thickness of the alloy sheet may be 0.01-1.5 mm, preferably 0.1-0.8 mm, more preferably 0.1-0.5 mm. Alloy ingots were prepared by casting. The thickness of the alloy ingot may be 2-50 mm, preferably 6-30 mm, more preferably 10-25 mm.

[0061] The hydrogen storage alloy is obtained by heat-treating the solid alloy at a temperature of 850-1050° C. for 10-50 h under a vacuum degree below -0.1 Pa. Heat treatment can be performed in an inert atmosphere. The inert atmosphere can be argon or nitrogen, etc. The vacuum degree is a relative vacuum degree, and its value is below -0.1Pa, preferably -0.1~-0.001Pa, more preferably -0.09~-0.01Pa, most preferably -0.03~-0.01Pa. The heat treatment temperature may be 850-1050°C, preferably 800-1000°C, more preferably 900-1000°C. The heat treatment time is 10-50 h, preferably 15-30 h, more preferabl...

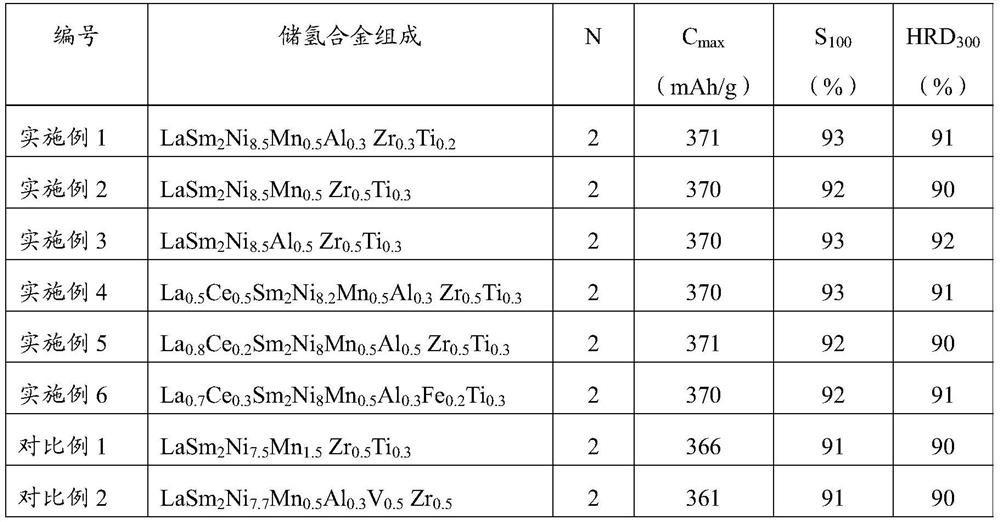

Embodiment 1~6

[0071] Prepare metal raw materials according to the hydrogen storage alloy formula in Table 1, and put the metal raw materials into a vacuum induction melting furnace. Wash the furnace with argon gas 5 times, evacuate the vacuum induction melting furnace to 2Pa, and fill it with argon until the pressure in the vacuum induction melting furnace is -0.055MPa.

[0072] Heat and melt the metal raw material at 1500°C. When the temperature of the melt reaches 1430° C., the melt is cast to a cooling copper roll, and flakes are flaked into alloy flakes (thickness is 0.2 mm).

[0073] The alloy sheet was placed in a vacuum treatment furnace and heat-treated at -0.01Pa and 950°C for 16h under the protection of argon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com