ab 3 Type gadolinium-containing hydrogen storage alloy, electrode, battery and preparation method thereof

A hydrogen storage alloy and electrode technology, applied in the direction of negative electrode, nickel storage battery, battery electrode, etc., can solve the problems of low Mg melting point, low capacity retention rate, low energy density, etc., achieve high maximum discharge capacity and fewer activation cycles , The effect of high capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

[0080] The raw materials of the hydrogen storage alloy composition shown in Table 1 were put into a vacuum induction melting furnace, and the furnace was washed 5 times with high-purity inert gas. The vacuum induction melting furnace is evacuated to 2Pa and then filled with inert gas until the pressure in the vacuum induction melting furnace is -0.055MPa. The raw material is melted into an alloy melt at 1400°C, and then the heating is stopped. When the temperature of the alloy melt reaches 1350° C., the alloy melt is cast to a cooling copper roll, and flakes are flaked into alloy flakes with a thickness of 0.2 mm. The alloy sheet was placed in a vacuum treatment furnace, and under the protection of inert gas, heat treatment was carried out for 16 hours at a vacuum degree of -0.05Pa and a temperature of 950°C.

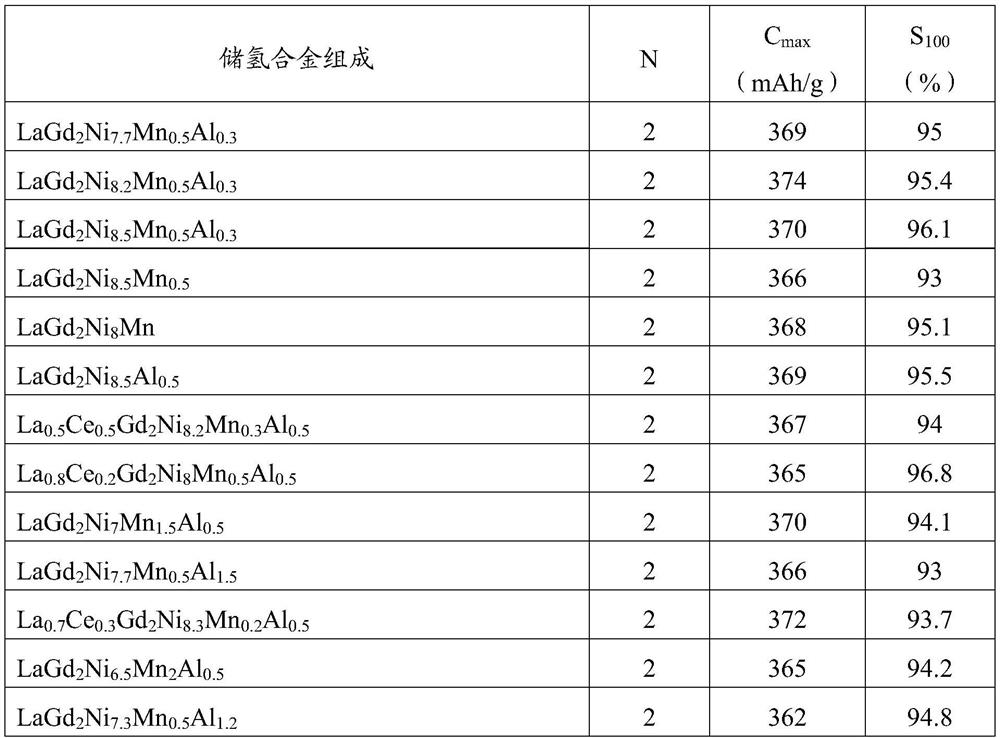

[0081] Table 1

[0082] serial number Hydrogen Storage Alloy Composition Example 1 LaG 2 Ni 7.7 mn 0.5 Al 0.3

Embodiment 14~26

[0084] The hydrogen storage alloys of Examples 1 to 14 were mechanically broken into hydrogen storage alloy powders of 200 to 300 meshes, and the hydrogen storage alloy powders with a mass ratio of 1:4 were mixed with carbonyl nickel powders, and the diameters were made into 15 mm under a pressure of 11 MPa. negative electrode material. The negative electrode material was placed between two sheets of nickel foam, and at the same time, a nickel strip as a tab was sandwiched, and then pressed under a pressure of 11 MPa to obtain an electrode. The spot welding around the negative electrode material ensures the close contact between the electrode sheet and the nickel foam. The electrochemical performance of the test is shown in Table 2.

[0085] Table 2

[0086]

[0087] N: the number of cycles required for the electrode to be fully activated;

[0088] C max : The maximum discharge capacity of the electrode;

[0089] S 100 : The capacity retention rate of the electrode fo...

Embodiment 27~39

[0091] The battery includes a battery case and a negative electrode, a positive electrode, a reference electrode, an electrolyte and a separator packaged in the battery case. Using the electrodes of Examples 14 to 26 as negative electrodes, sintered Ni(OH) with excess capacity 2 The / NiOOH electrode is the positive electrode, Hg / HgO is the reference electrode, 6mol / L KOH solution is used as the electrolyte, polyethylene is used as the diaphragm, and the battery is assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com