Top-blowing powder spraying method for electric furnace smelting

An electric furnace smelting and top blowing technology, applied in the direction of electric furnaces, furnaces, furnace types, etc., can solve problems such as uneven mixing in the full flow field, tight combination of spray guns and furnace walls, deformation and bending of obliquely inserted gun rods, and reach the installation limit of the furnace top. High requirements are low, improving the effect of smelting and improving the refining rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

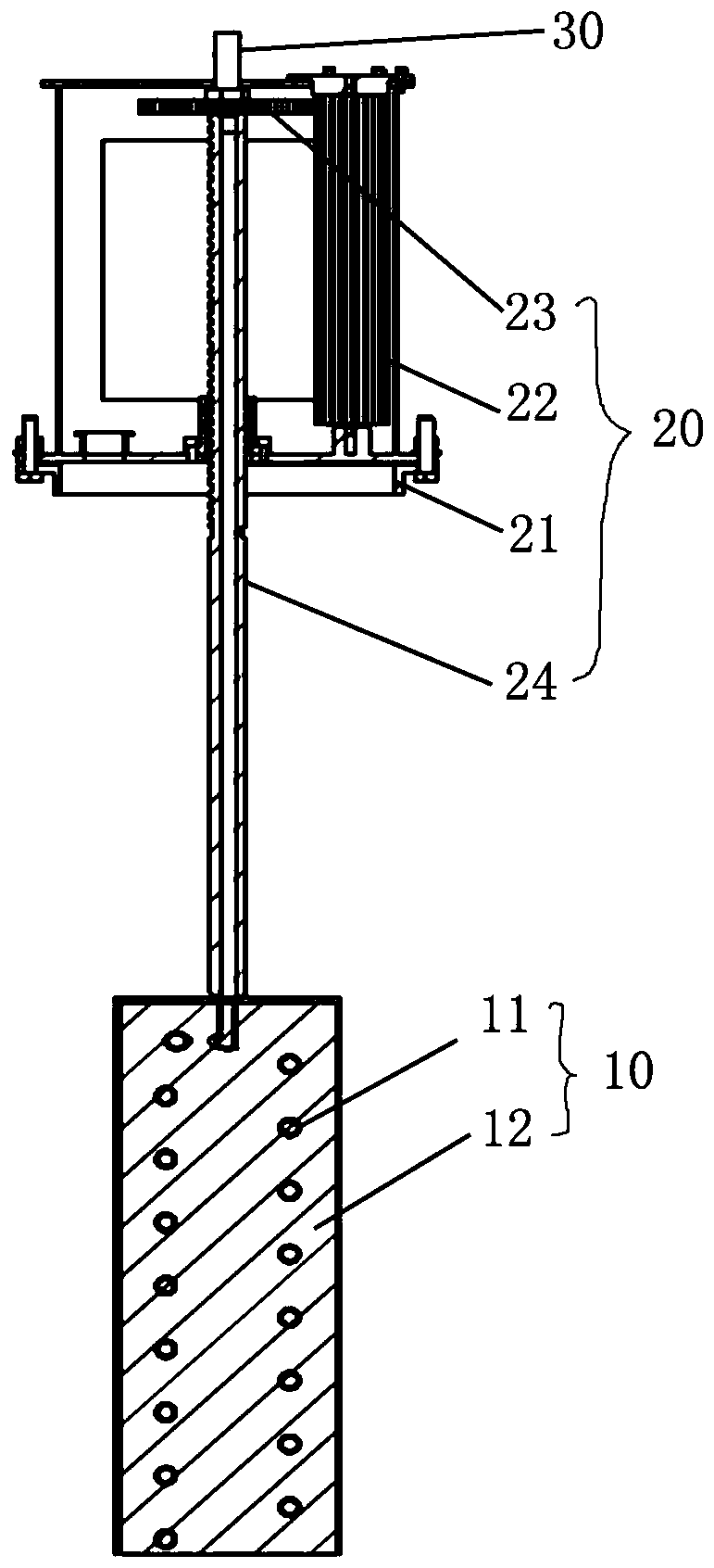

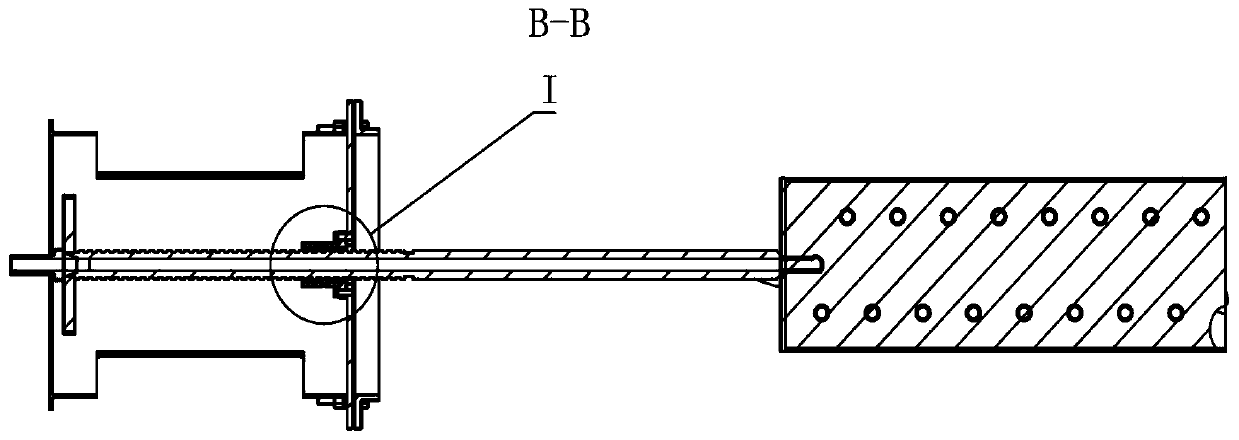

[0024] Hereinafter, the top blowing powder injection method for electric furnace smelting of the present invention will be described in detail with reference to exemplary embodiments. It should be understood that, in the present invention, the terms "upper end" and "lower end", "upper end" and "lower end" are for the convenience of describing the relative structural relationship of different components, rather than strict positional restrictions, for example, when When the telescopic rotary joint in the present invention is laid flat in the non-installed state, the "upper end" and "lower end", "upper end" and "lower end" can also be referred to as "left end" and "right end", " Left End” and “Right End”. In addition, the terms "first", "second", and "third" are only used to distinguish different components, and are not strictly limited to the order.

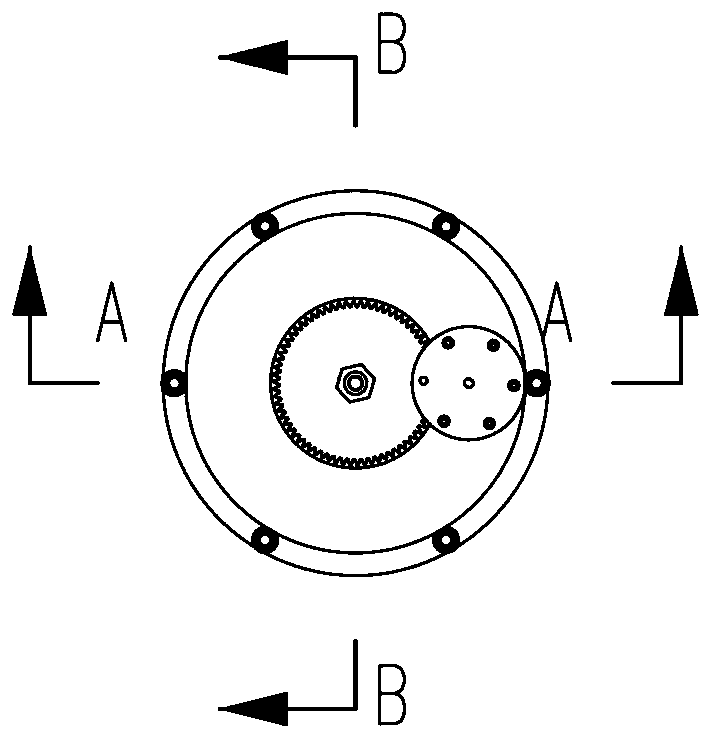

[0025] In order to more clearly and completely describe an exemplary embodiment of the method for top-blown powder injection in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com