Electric arc furnace and furnace cover thereof

A technology of electric arc furnace and furnace cover, which is applied in the field of electric arc furnace, can solve the problems of reduced resource utilization, uneven temperature distribution, increased energy consumption, etc., and achieve the effects of reduced consumption, uniform temperature in the furnace, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

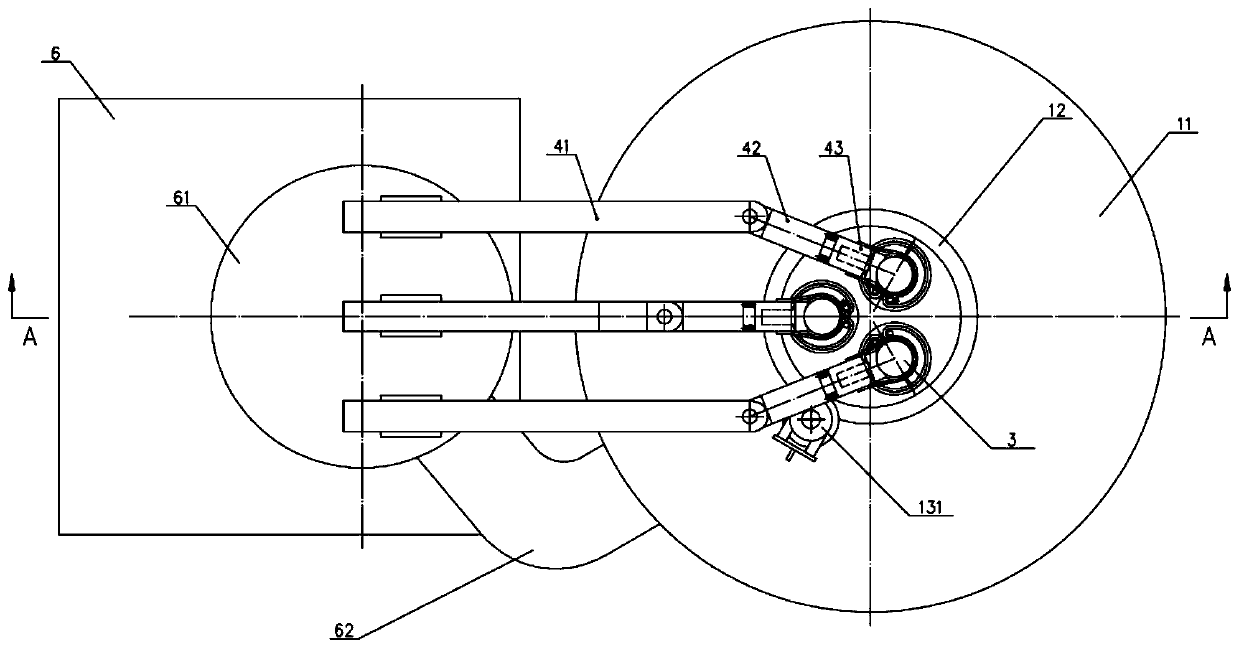

[0029] Such as figure 1 and Figure 7 , the embodiment of the present invention provides a furnace cover 1 for an electric arc furnace, including a fixed cover 11 and a movable cover 12, the movable cover 12 is provided with at least one electrode penetration installation position, and the fixed cover 11 is An electrode rotation drive mechanism for driving the movable cover 12 to rotate around its own axis is provided.

[0030] The above-mentioned fixed cover 11 is spliced with the above-mentioned movable cover 12 to form a furnace cover 1 that can cover and close the electric arc furnace body 2, that is, a hole is opened on the fixed cover 11 to install the movable cover 12, and through the movable The cover 12 closes the opening.

[0031] It can be understood that the movable cover 12 can rotate around its own axis, so it is preferably a circular / cylindrical cover or a conical / truncated cone cover. The above-mentioned fixed cover body 11 is basically the same as the exi...

Embodiment 2

[0044] Such as Figure 1-Figure 3 This embodiment provides an electric arc furnace, including a furnace body 2 and a furnace cover 1. The furnace cover 1 is preferably the furnace cover 1 provided in the first embodiment above, and the specific structure of the furnace cover 1 will not be repeated here. Wherein, the fixed cover body 11 is covered on the furnace body 2 , and the electrodes 3 are correspondingly pierced at the positions where the electrodes are pierced. As mentioned above, the number of electrodes 3 is generally three, which are evenly spaced around the central axis of the furnace body 2 / fixed cover 11 / movable cover 12 .

[0045] Further optimize the above embodiment, such as Figure 1-Figure 3 Each electrode 3 is equipped with an electrode clamping arm 4 and an electrode lifting drive mechanism 5 for driving the electrode clamping arm 4 up and down, and the electrode clamping arm 4 is driven up and down by the electrode lifting drive mechanism 5, which can d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com