Treatment method of arsenic-containing organic wastewater

A technology of organic wastewater and treatment methods, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., to achieve the effects of improving utilization rate, simplifying process flow, reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

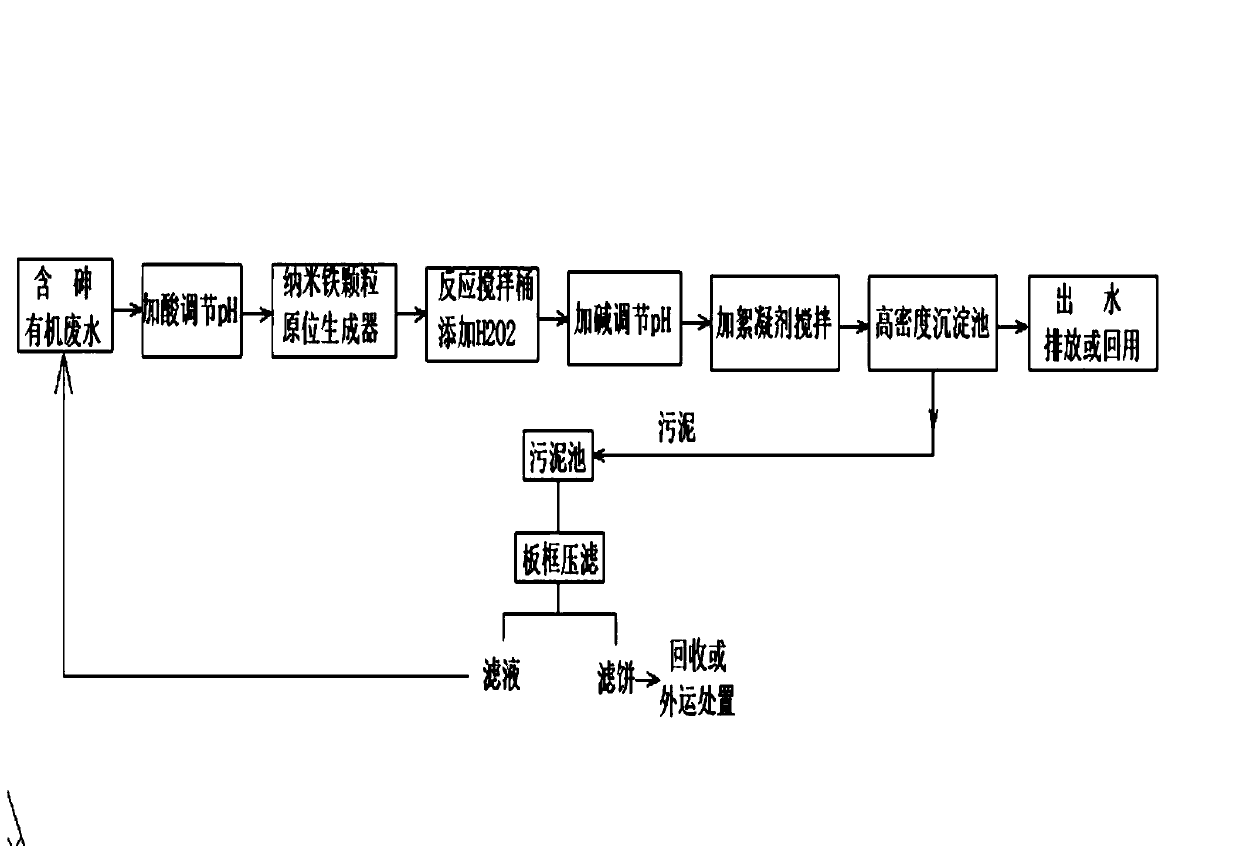

Method used

Image

Examples

Embodiment

[0051] Example: Water quality of arsenic-containing wastewater from an arsenic product enterprise:

[0052] Arsenic-containing acid-alkali wastewater: pH=6, arsenic content in wastewater TAs=200mg / L, COD=150mg / L, wastewater production 10m 3 / day, collected up to 800m 3 Reconciliation pool pending.

[0053] Step 1: Pump the arsenic-containing wastewater in the adjustment tank to a 400L mixing tank, adjust the pH of the wastewater to 3 with dilute sulfuric acid, set a 500L reaction tank downstream of the mixing tank, and set up a connecting pipeline between the mixing tank and the reaction tank The nano-iron particle generation device controls the flow rate of the waste water from the 400L mixing tank into the 500L reaction tank to be 1m3 / hour. The waste water enters the 500L reaction barrel;

[0054] Step 2: Dosing H into the reaction barrel 2 o 2 , the metering pump flow rate is set to 3.5L / hour, H 2 o 2 The molar ratio to iron is 3:1, ORP>450mV is controlled, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com