Coating material for functional interlayer of lithium-sulfur battery and preparation method thereof

A coating material, a technology for lithium-sulfur batteries, applied in lithium batteries, carbon preparation/purification, battery pack components, etc. Chemical adsorption capacity, large specific surface area, effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

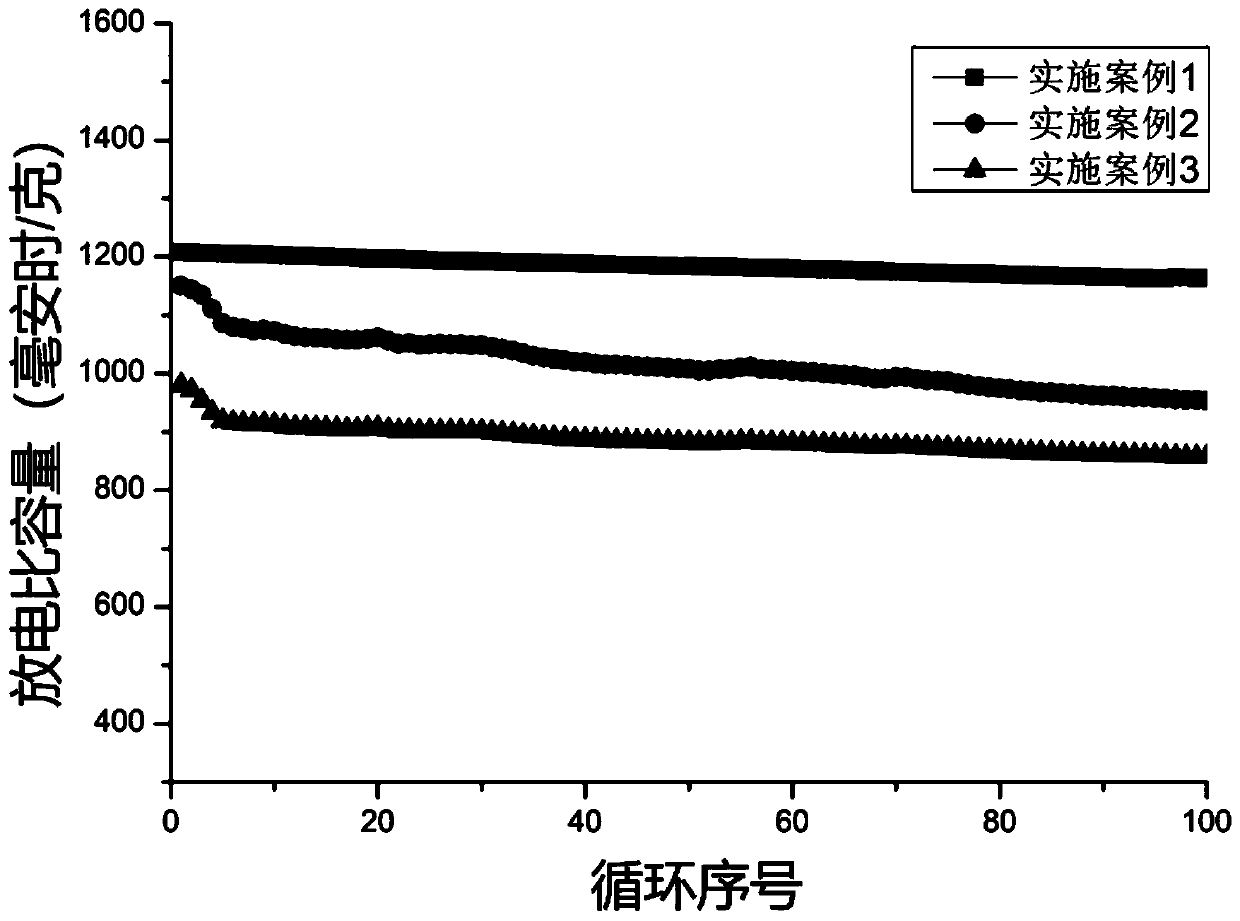

Embodiment 1

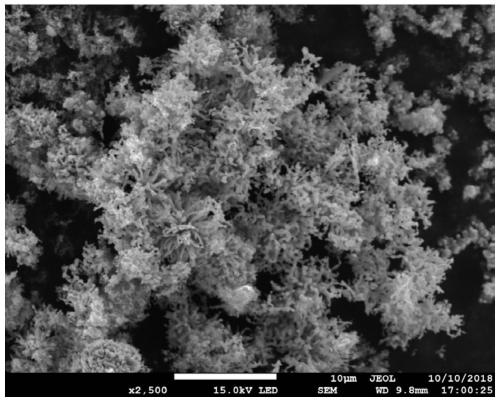

[0024] The coating material used for the functional interlayer of the lithium-sulfur battery is a sea urchin-like carbon-coated cobalt sulfide composite material.

[0025] The preparation method of the coating material for the functional interlayer of lithium-sulfur battery comprises the following steps:

[0026] (1) Preparation of sea urchin-like cobalt tetroxide: First, weigh 0.2g of cobalt chloride and dissolve it in 10mL of deionized water and stir it on a magnetic stirrer for 2h to obtain a cobalt chloride solution; weigh 2g of urea and dissolve it in 10mL of deionized water on a magnetic stirrer Stir for 2 hours to obtain a urea solution; then add the cobalt chloride solution into the urea solution, stir evenly, place it in a 150mL reactor, react for 6 hours at 150°C, and cool to room temperature naturally. Each was centrifuged and washed 3 times, dried at 60°C for 12 hours, and then placed in a muffle furnace for calcination at 200°C to obtain sea urchin-like cobalt tet...

Embodiment 2

[0031] The preparation method of the coating material for the functional interlayer of lithium-sulfur battery comprises the following steps:

[0032] (1) Preparation of sea urchin-like cobalt tetroxide: First, weigh 0.1g of cobalt chloride and dissolve it in 20mL of deionized water and stir it on a magnetic stirrer for 3h to obtain a cobalt chloride solution; weigh 1g of urea and dissolve it in 20mL of deionized water on a magnetic stirrer Stir for 3 hours to obtain a urea solution; then add the cobalt chloride solution into the urea solution, stir evenly, place it in a 150mL reactor for 4 hours at 120°C, and cool it down to room temperature naturally. Each was centrifuged and washed 3 times, dried at 60°C for 12 hours, and then placed in a muffle furnace for calcination at 150°C to obtain sea urchin-like cobalt tetroxide powder;

[0033] (2) Preparation of sea urchin-shaped carbon-coated cobalt oxide: Weigh 0.2 g of sea urchin-shaped cobalt tetroxide powder obtained in step (...

Embodiment 3

[0036] The preparation method of the coating material for the functional interlayer of lithium-sulfur battery is characterized in that it comprises the following steps:

[0037] (1) Preparation of sea urchin-like cobalt tetroxide: first weigh 0.4g of cobalt chloride and dissolve it in 20mL of deionized water and stir it on a magnetic stirrer for 1h to obtain a cobalt chloride solution; weigh 4g of urea and dissolve it in 20mL of deionized water on a magnetic stirrer Stir for 1 hour to obtain a urea solution; then add the cobalt chloride solution into the urea solution, stir evenly, place it in a 150mL reactor, react for 8 hours at 170°C, and cool to room temperature naturally. Each was centrifuged and washed 3 times, dried at 60°C for 12 hours, and then placed in a muffle furnace for calcination at 300°C to obtain sea urchin-like cobalt tetroxide powder;

[0038] (2) Preparation of sea urchin-shaped carbon-coated cobalt oxide: Weigh 0.6 g of sea urchin-shaped cobalt tetroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com