Reactive waterproof coating

A kind of waterproof coating, reactive technology, applied in the direction of asphalt coating, natural resin coating, chloroprene homopolymer coating, etc., can solve the problem of no waterproof coating, improve the bonding strength and weather resistance, waterproof Long-lasting reliability and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

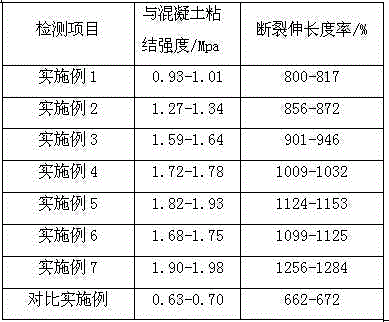

Examples

Embodiment 1

[0017] Take 20 parts of styrene-butadiene rubber latex with a solid content of 42 ± 0.5%, add 30 parts of styrene-butadiene rubber modified emulsified asphalt with a solid content of 42 ± 0.5% and 0.2 part of lauric acid rare earth compound under normal temperature stirring, and stir evenly to obtain a reaction Type waterproof coating.

Embodiment 2

[0019] Take 30 parts of neoprene rubber latex with a solid content of 50 ± 0.5%, add 20 parts of neoprene rubber modified emulsified asphalt with a solid content of 50 ± 0.5% and 0.6 parts of aluminum zirconate waterproof bridging agent under normal temperature stirring Uniform, get reactive waterproof coating.

Embodiment 3

[0021] Take 40 parts of SBS rubber latex with a solid content of 60±0.5%, add 60 parts of emulsified asphalt with a solid content of 60±0.5% and 1 part of trioctyltin chloride under normal temperature stirring, and stir evenly to obtain a reactive waterproof coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com