A self-supporting functional interlayer for lithium-sulfur batteries and its preparation method

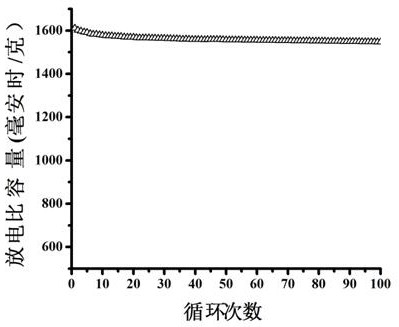

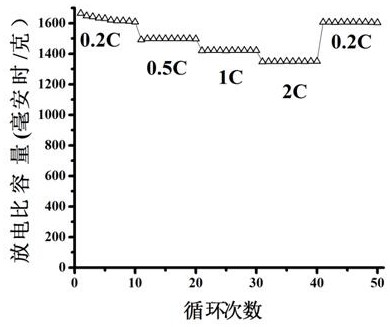

A self-supporting film, copper sulfide technology, applied in the field of material chemistry, can solve the problems of low conductivity of sulfur and lithium sulfide, damage to electrode structure, difficult operation, etc., and achieve excellent rate performance, large specific surface area, and multiple storage sites. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of nitrogen-doped MXene:

[0027] Immerse the ground MAX phase ceramic powder in HF solution with a mass concentration of 40%, the mass ratio of ceramic powder to HF solution is 1:20, heat up to 60°C, stir magnetically for 18 hours, then centrifuge to obtain the product, and use deionized water Wash until neutral, and dry in an oven at 70°C for 18 hours to obtain MXene. The obtained MXene was placed in a tube furnace, heated to 400°C under an argon atmosphere, passed through ammonia gas, and kept for 30 minutes, then the ammonia gas was turned off, and cooled with the furnace under an argon atmosphere to obtain nitrogen-doped MXene. Wherein the MAX phase ceramic is Ti 3 AlC 2 . Get MXene material as Ti 3 C 2 T x .

[0028] (2) Preparation of nitrogen-doped MXene composite copper sulfide self-supporting film:

[0029] 0.8 g of copper sulfate, 0.8 g of thioacetamide and 1.5 g of the nitrogen-doped MXene prepared in step (1) were dissolved in 80 mL ...

Embodiment 2

[0033] (1) Preparation of nitrogen-doped MXene:

[0034]Immerse the ground MAX phase ceramic powder in HF solution with a mass fraction of 30%, the mass ratio of ceramic powder to HF solution is 1:30, heat up to 50°C, stir magnetically for 12 hours, then centrifuge to obtain the product, and use deionized water Wash until neutral, and dry in an oven at 60°C for 12 hours to obtain MXene. The obtained MXene was placed in a tube furnace, heated to 300°C under an argon atmosphere, passed through ammonia gas, and kept for 20 minutes, then the ammonia gas was turned off, and cooled with the furnace under an argon atmosphere to obtain nitrogen-doped MXene. Wherein the MAX phase ceramic is Ti 3 AlC 2 . Get MXene material as Ti 3 C 2 T x (T x are -OH, -F and other functional groups).

[0035] (2) Preparation of nitrogen-doped MXene composite copper sulfide self-supporting film:

[0036] 0.5 g of copper sulfate, 0.5 g of thioacetamide and 1 g of the nitrogen-doped MXene prepare...

Embodiment 3

[0038] (1) Preparation of nitrogen-doped MXene:

[0039] Immerse the ground MAX phase ceramic powder in HF solution (mass fraction is 50%), the mass ratio of ceramic powder to HF solution is 1:10), heat up to 90°C, stir magnetically for 24 hours, then centrifuge to obtain the product, use The MXene was obtained by washing with ionized water to neutrality and drying in an oven at 80°C for 24 hours. The obtained MXene was placed in a tube furnace, heated to 500°C under an argon atmosphere, passed through ammonia gas, and kept for 40 minutes, then the ammonia gas was turned off, and cooled with the furnace under an argon atmosphere to obtain nitrogen-doped MXene. Wherein the MAX phase ceramic can be Ti 3 AlC 2 . The obtained MXene material can be Ti 3 C 2 T x (T x are -OH, -F and other functional groups).

[0040] (2) Preparation of nitrogen-doped MXene composite copper sulfide self-supporting film:

[0041] 1 g of copper sulfate, 1 g of thioacetamide and 2 g of the nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com