Production process of mobile phone heat dissipation plate

A technology for mobile phone heat dissipation and production process, which is applied in photosensitive material processing, cooling/ventilation/heating transformation, and modification through conduction heat transfer, etc. Problems such as cumbersome operations, to achieve the effect of improving the uniformity of the finished product, the stability of the fit and the matching degree, and the ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

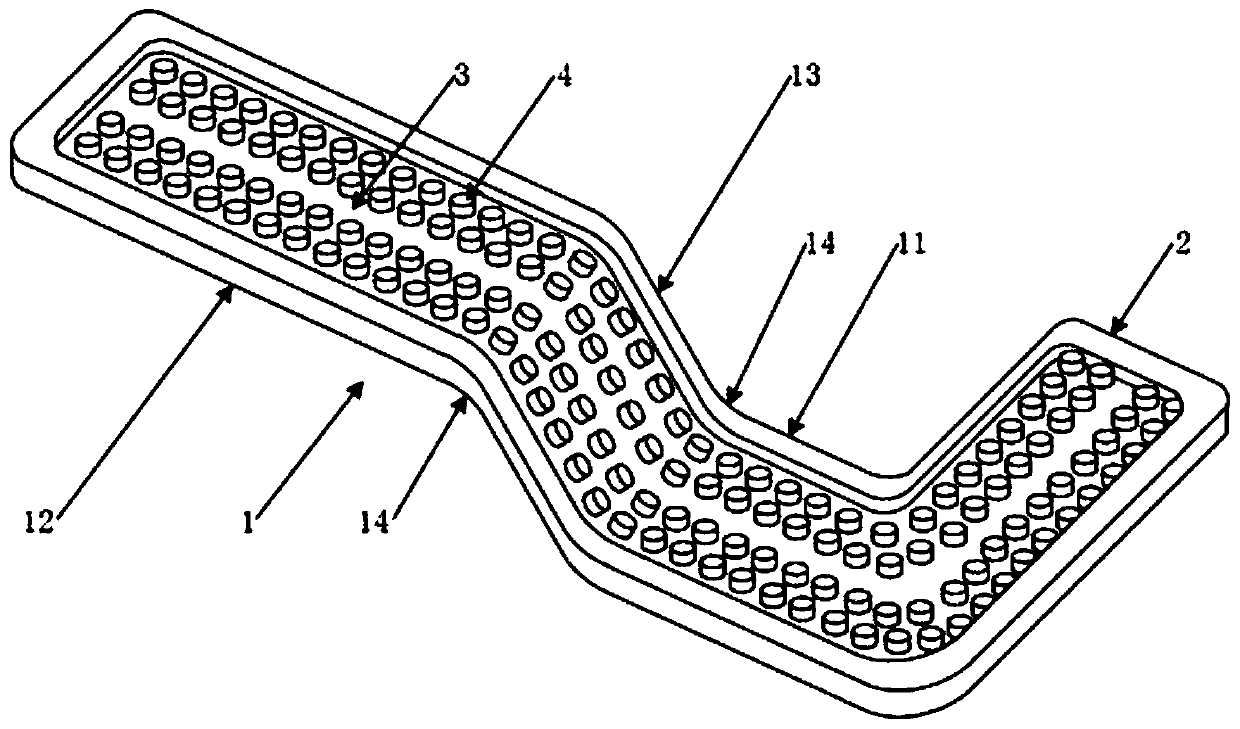

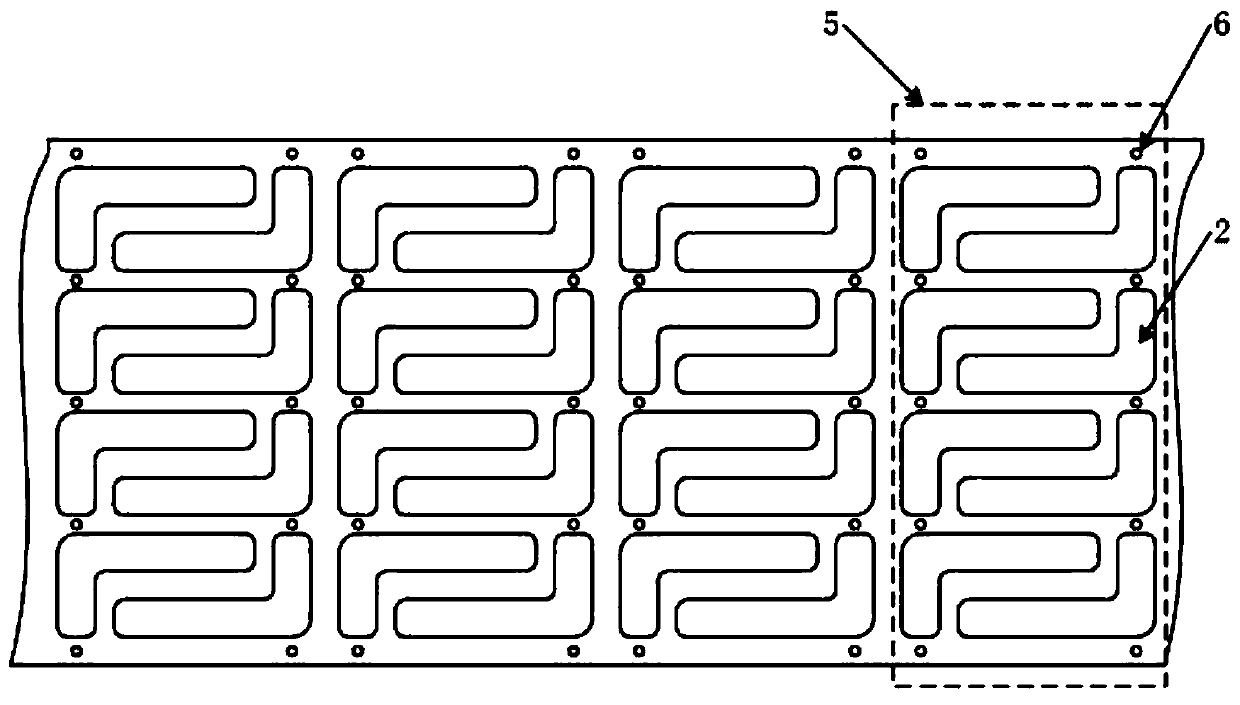

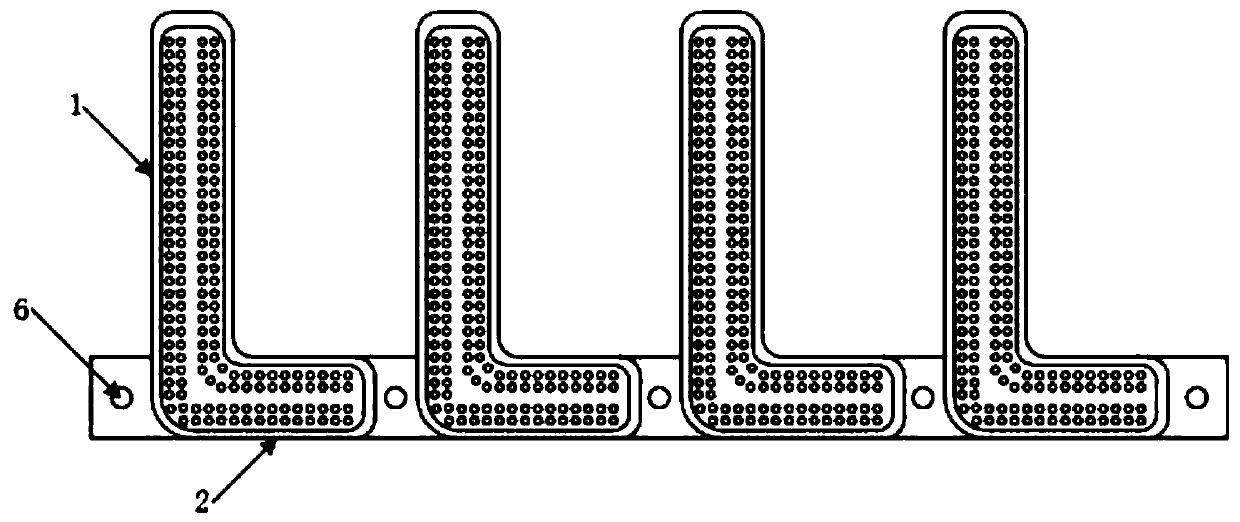

[0027] The invention provides a production process of a mobile phone cooling plate. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

[0028] The production process of mobile phone heat sink, such as figure 1 As shown, the mobile phone cooling plate includes an L-shaped copper plate main body formed by the first edge 1 and the second edge 2. The L-shaped copper plate main body has a sink cavity 3, and a number of raised heat dissipation columns 4 are arranged in the sink cavity 3. The first edge 1 It is a bent plate body with a bent section.

[0029] Specifically, the mobile phone heat sink in this case is the bottom plate of the traditional VC balanced heat sink. The traditional VC balanced heat sink is in a flat state, including the bottom plate, cover plate, and filling mesh layer. The process of this case aims to manufacture a heat dissipation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com