Steel bar grinding and washing device assembly

A technology for washing devices and steel bars, applied in grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve problems such as low processing efficiency of steel bars, and achieve outstanding practicability, simple design, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

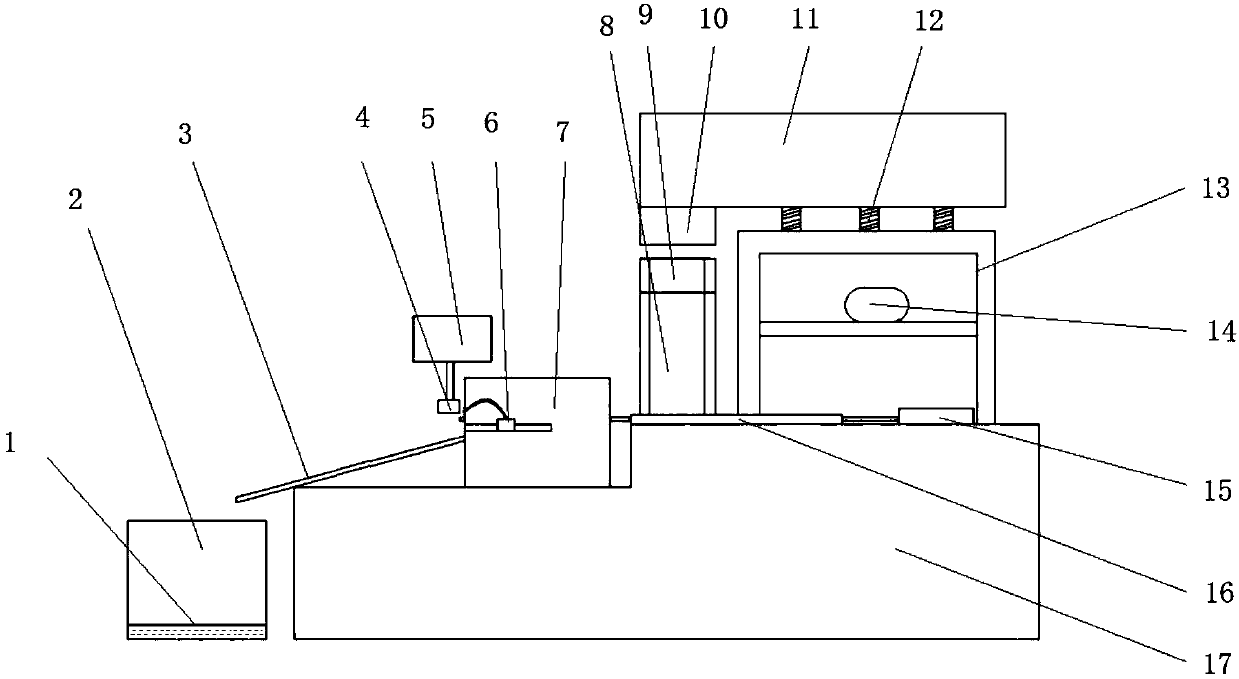

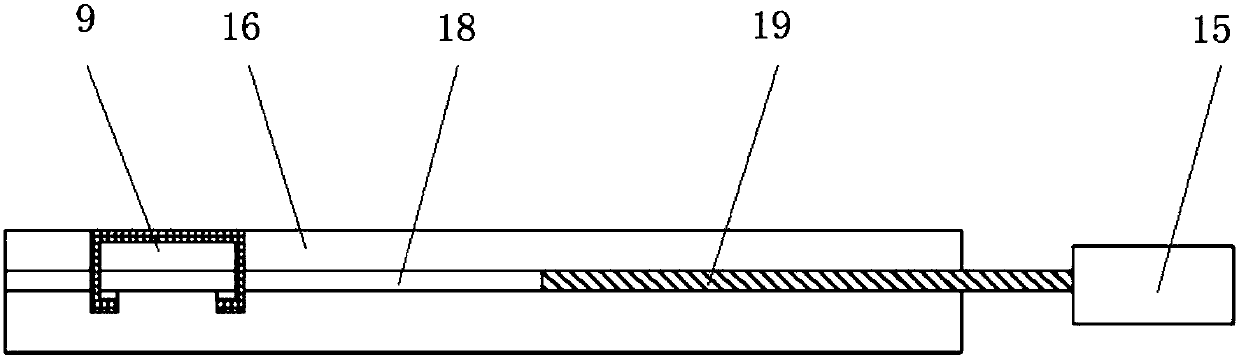

[0028] Such as figure 1 and figure 2 As shown, a steel bar grinding and washing device assembly includes a vibrating device, a material pushing device, a clamping device 7, a grinding device, a washing device 6 and a material receiving device, a material pushing device, a clamping device 7, a grinding device and a washing device The device 6 is placed on the base 17 in sequence, the base 17 is stepped, the pushing device is placed on a high-level step, the vibrating device is placed above the pushing device, the clamping device 17, the grinding device and the washing device 6 are placed on the same Low-level steps; the vibration device is made up of support 13, motor 14 and vibration box 11, motor 14 is placed on the support 13, vibration box 11 is placed on the top of support 13 by spring 12, the top opening of the vibration box 11, its bottom plate is a slope, The lower end of the bottom plate is provided with a discharge port 10, and a material guide plate is provided bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com