Integrated magnetic component

A technology of magnetic components and magnetic cores, applied in transformer/inductor parts, electrical components, magnetic cores/yokes, etc., can solve problems such as reducing the insulation properties of coils, and achieve effective heat dissipation, high-efficiency heat dissipation, and high energy density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

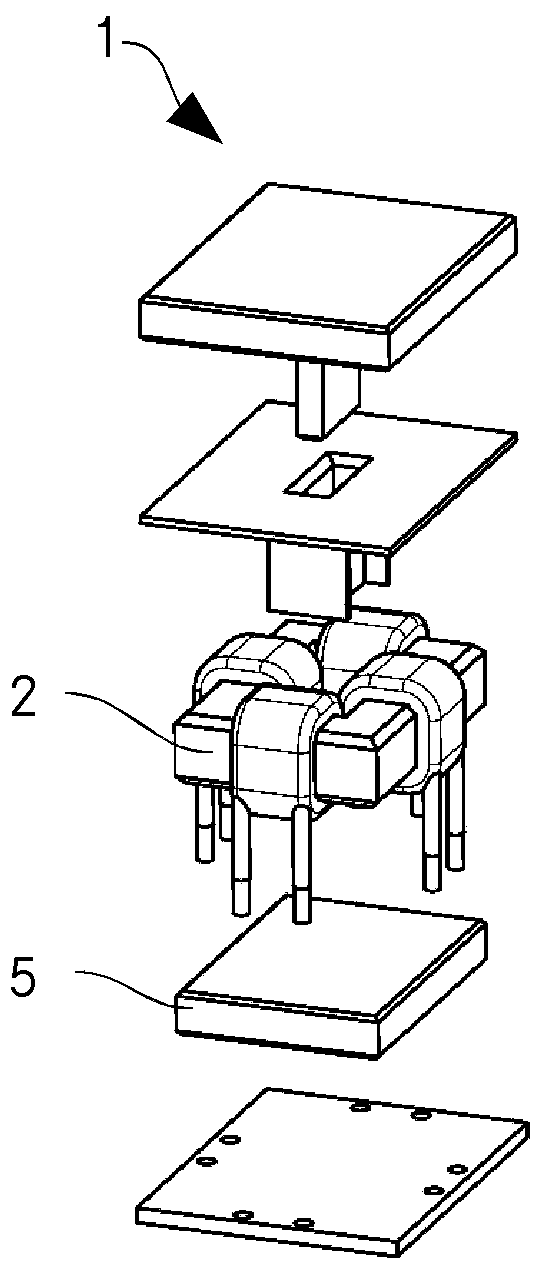

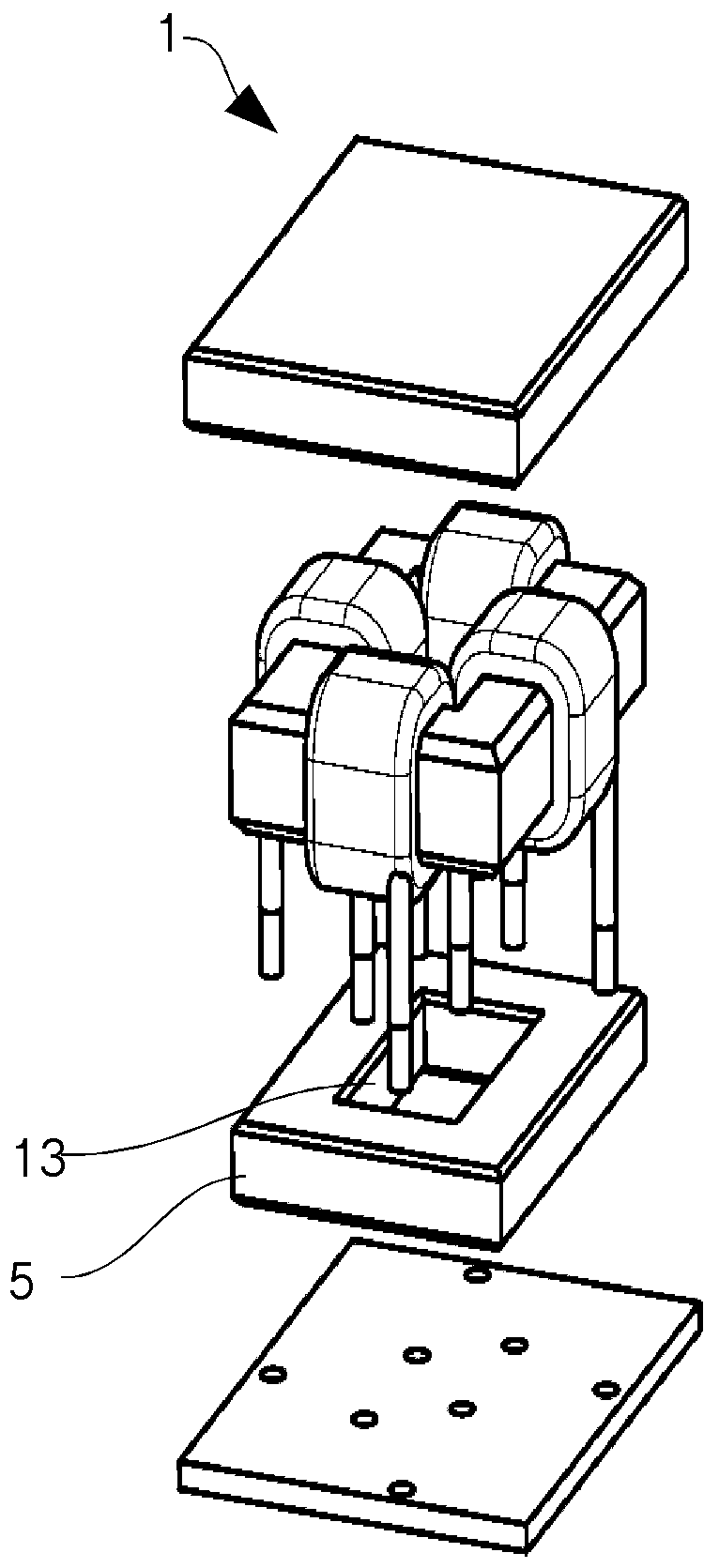

[0114] figure 1 An exploded view of an integrated magnetics component 1 with an annular common mode core 2 is shown. Two windings 4 are wound around the common mode core 2 and pass through the winding window 3 . The bar-shaped differential mode magnetic core 5 comprises a surface 6 which, when placed in the remaining space of the winding window 3, is adjacent to each of the two windings 4 (see also figure 2 ). The surface 6 of the bar-shaped differential mode core 5 has the same distance to each of the two windings 4 as the common mode core 2 has. In other words, the two windings 4 are tightly wound around the common-mode magnetic core 2 , and the rod-shaped differential-mode magnetic core 5 is tightly fitted into the remaining space of the winding window 3 . Each of the two windings 4 comprises two terminals 7 (only one terminal is shown per winding), which are arranged through openings 8 of a printed circuit board (PCB) 9 .

[0115] figure 2 shows the basis figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com