cut off cutting tool

A cutting tool and metal cutting technology, applied in the direction of tool holder, cutting blade, manufacturing tool, etc., can solve the problems of coolant limitation, cutting cutting tool flat, etc., and achieve the effect of high cutting efficiency and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

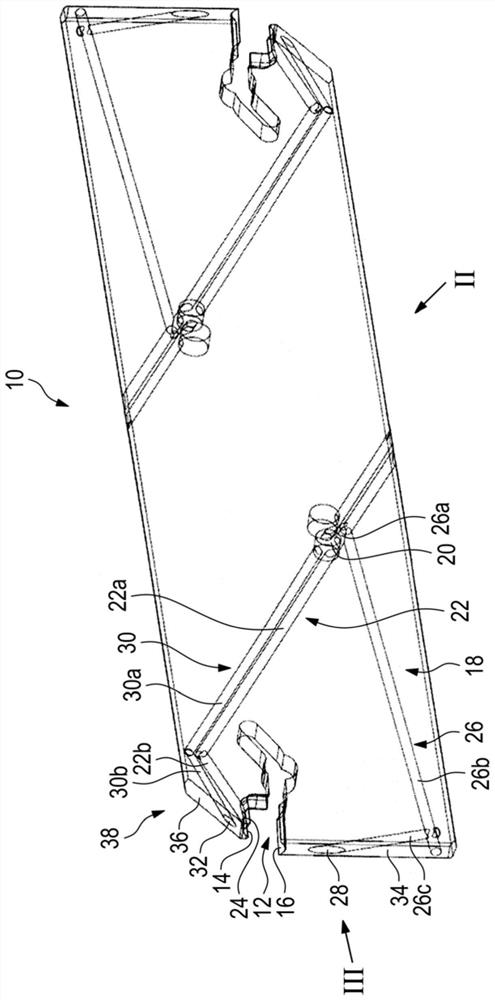

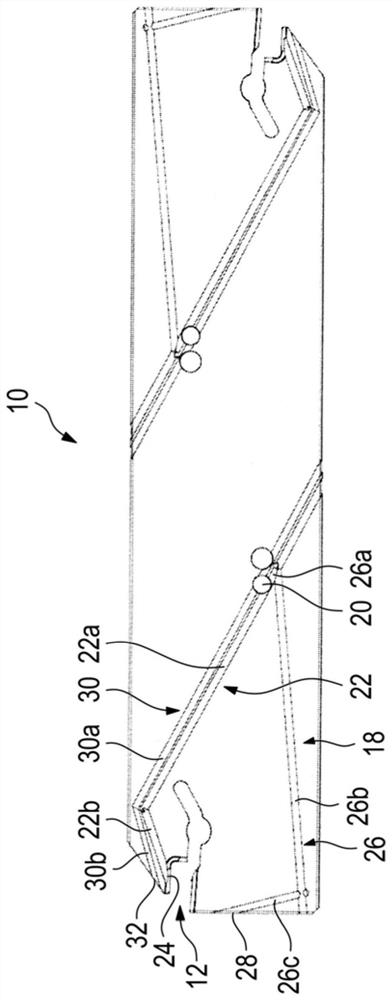

[0036] Figures 1 to 3 show a parting cutting tool 10 for cutting metal working.

[0037] The severing cutting tool 10 may also be referred to as a severing sword.

[0039] The severing cutting tool 10 also includes an internal coolant supply system 18 for supplying coolant to the cutting area.

[0040] A coolant supply opening 20 is provided on the parting cutting tool 10 on the part of the tool holder or on the lathe for this purpose.

[0042] The severing cutting tool 10 is thus supplied with coolant through the coolant supply aperture 20.

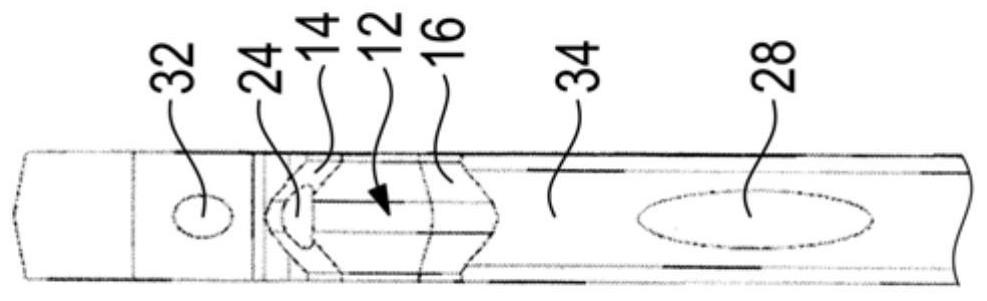

[0044] The coolant lines 22, 26, 30 are here in fluid connection with the associated coolant outlets 24, 28, 32, respectively.

[0045] Furthermore, these coolant lines run within the cutting tool 10 for severing.

[0047] The first coolant outlet is here configured to be in fluid connection with a coolant inlet of a cutting insert, not shown in detail.

[0049] The second coolant outlet 28 is provided at the workpiece-side end face 34 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com