A kind of as-cast ti6321 titanium alloy for ships and preparation method thereof

A ti6321 and titanium alloy technology, applied in the field of as-cast Ti6321 titanium alloy for ships and its preparation, to achieve the effects of refining the interlayer spacing, meeting material requirements, and optimizing heat treatment processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of cast Ti6321 titanium alloy for ships, comprising the steps of:

[0024] Step 1: Use modified Ti6321 titanium alloy and other raw materials to smelt as-cast Ti6321 alloy ingots with a Si element content of 0.13%~0.17%. After smelting, the other elements of the ingot are 6.2% Al, 3.0% Nb, 2.5% Zr and 1.0% Mo, the balance being Ti;

[0025] Step 2, casting the cast Ti6321 alloy ingot obtained in step 1 into castings and test bars, and then performing hot isostatic pressing and stress relief annealing on the cast castings and test bars;

[0026] Step 3: send the castings and test rods treated in step 2 into a vacuum solid melting furnace and heat them to 1015°C, then keep them warm for 1.5h, and then carry out argon-filled cooling. The cooling rate is controlled between 35°C / min and 45°C / min. When the temperature is lower than 200°C, it is ventilated and cooled, and then it is released when the temperature is lower than 40°C to obtain the desired pr...

Embodiment

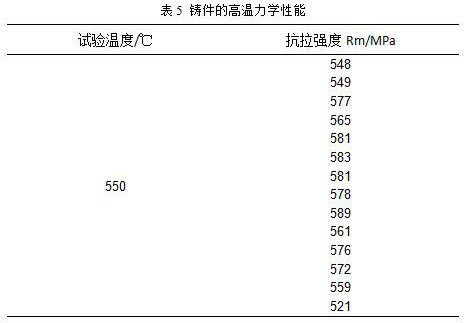

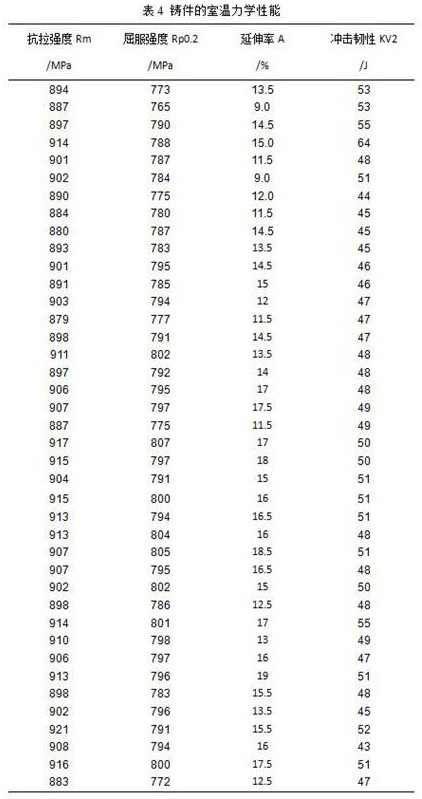

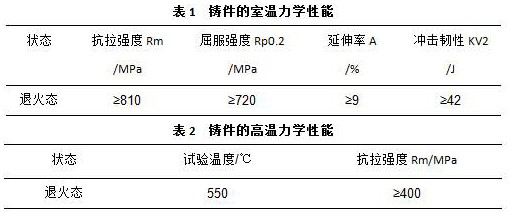

[0035] Embodiment: The present embodiment is the application of the cast Ti6321 titanium alloy for ships prepared by the method of the present invention, and the prepared titanium alloy material is cast into valve bodies, valve seats and valve covers for ships, and 40 Test rod, the size of the test rod is Φ15×120mm, the quantity and size of the valve body, valve seat and valve cover are shown in Table 3.

[0036]

[0037] The Si element content in the as-cast Ti6321 titanium alloy prepared in this example is 0.14%, and then it is casted in a vacuum shell-condensing furnace, and the casting mold is a machined graphite type to obtain the above-mentioned valve body, valve seat, valve cover and test rod , and then, after hot isostatic pressing treatment (910℃~930℃, heat preservation for 2 hours, cool to below 300℃ with the furnace), and then perform stress relief annealing (580℃, heat preservation for 1h, cool with the furnace to below 100℃ and release from the furnace) , follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com